Two-wheel drive intermittent rotary table

A technology of rotating table and double rollers, which is applied in the direction of manufacturing tools, transmission devices, transmission device parts, etc., can solve the problems of increased manufacturing costs, processing gaps and wear cannot be adjusted, energy loss, etc., to speed up production efficiency and improve bearings The effect of improving the service life and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

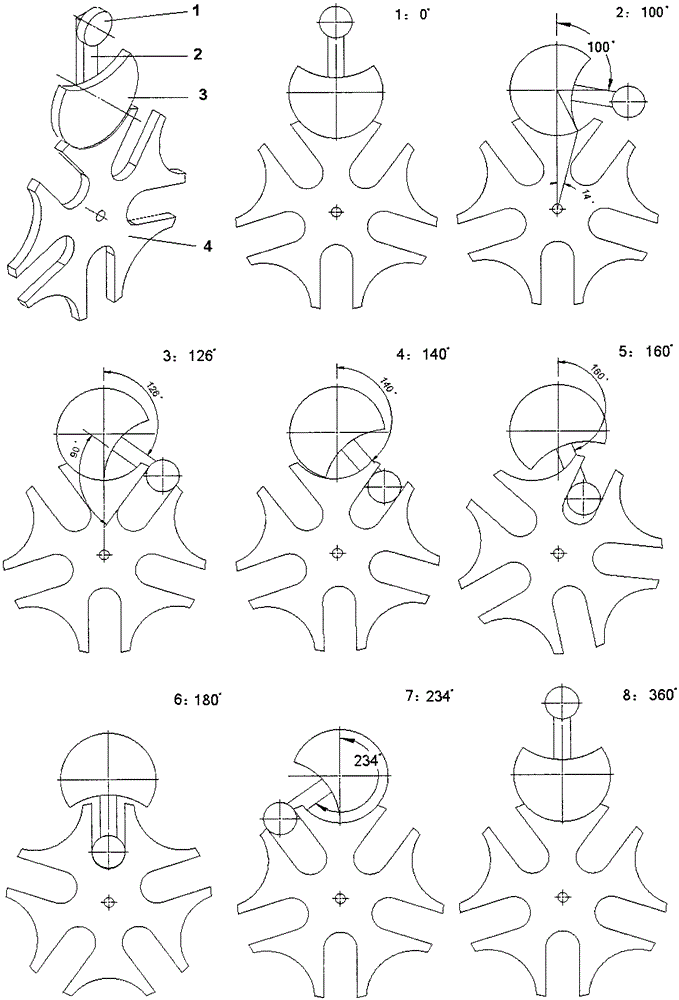

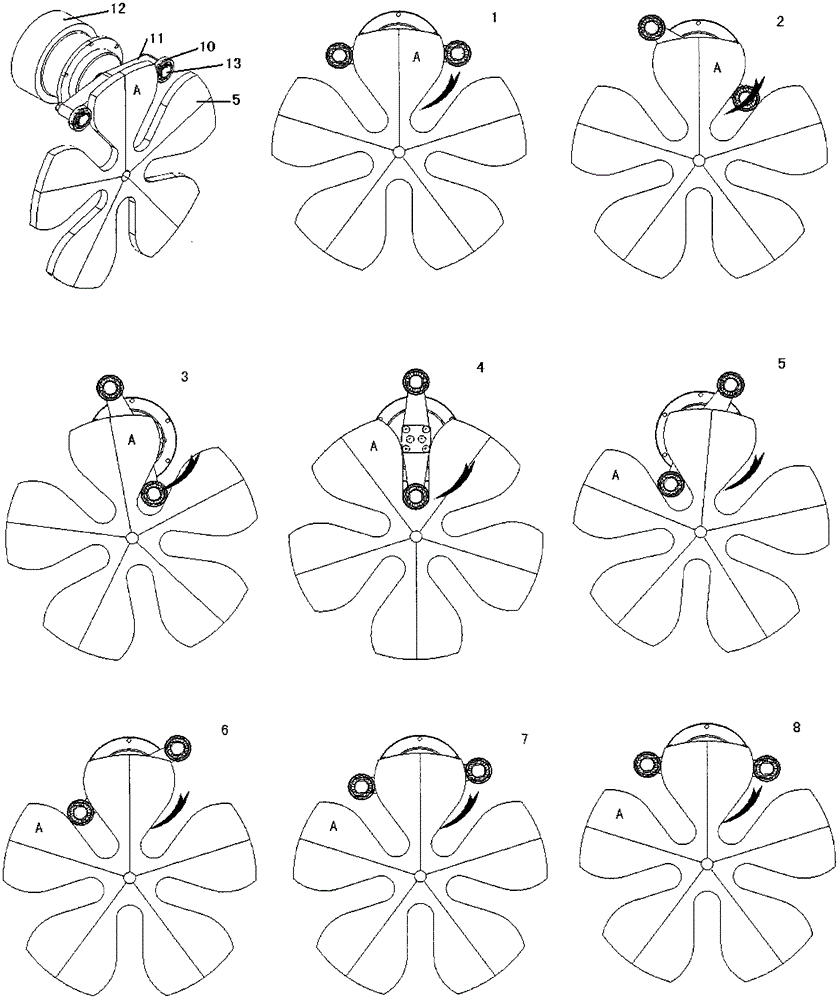

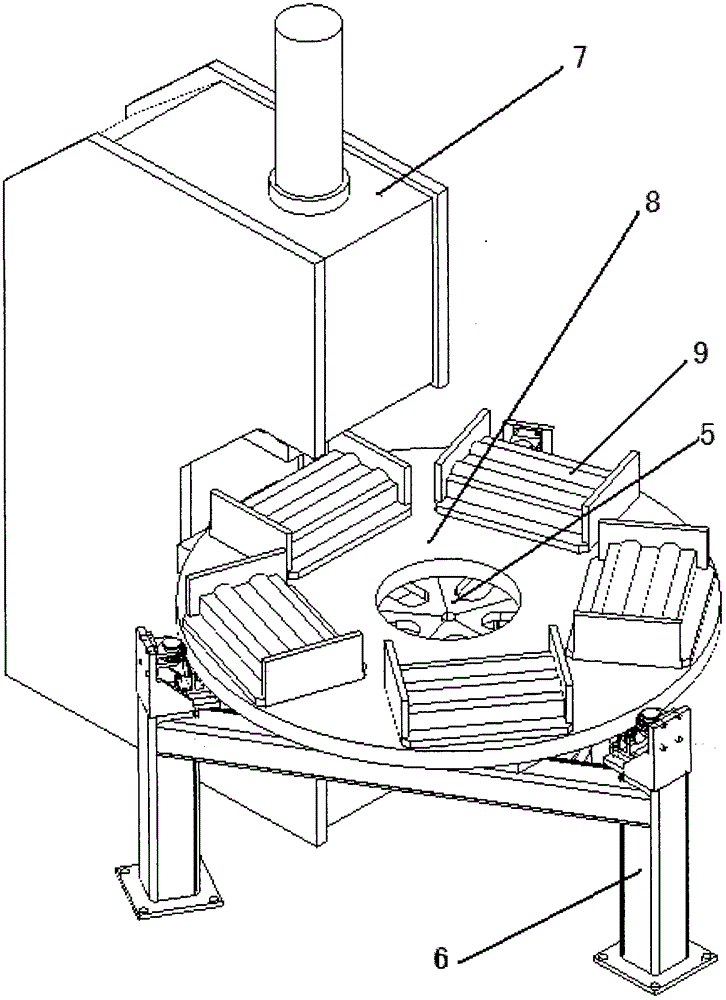

[0041] exist image 3 The main feature of the shown intermittent rotary table is that it uses a double-roller-driven intermittent rotary mechanism to complete the shift of the working position of the rotary table. movement and positioning tasks.

[0042] The double-roller driven intermittent rotation mechanism is composed of intermittent motion template (5), roller (10), rotating arm (11), hydraulic motor (12) or reducer, and electric motor; jointly complete the rotation of the rotary table (8) , acceleration, deceleration, braking, and positioning tasks. exist image 3 Among them, the stamping machine (7) drives the upper mold (21) to move up and down, the mold (9) is installed on the rotary table (8), the intermittent motion template (5) is connected with the rotary table (8), and the intermittent motion template (5) is an integral part of the double-roller-driven intermittent rotation mechanism, and the other part includes a rotating arm (11) and a roller (10) driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com