Adjustable non-nail chock

A technology of wheel chocks and rollers, which is applied in the field of fixed devices, can solve the problems affecting the mobility of troops, quick response ability, time-consuming and laborious removal of iron-plastic triangular wheel chocks, reinforcement of iron-plastic triangular wheel chocks, etc., to achieve good management and fast speed , good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

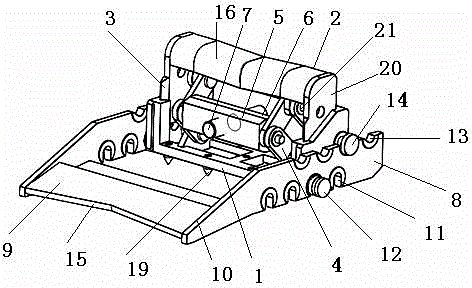

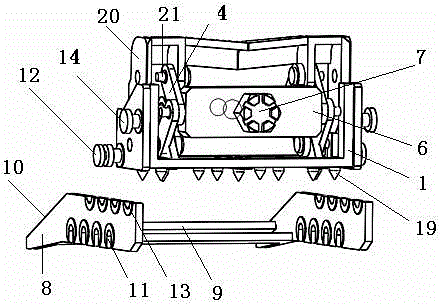

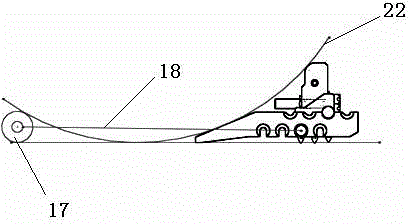

[0022] see figure 1 , 2 The names of the main parts are: anti-skid seat 1, beam 2, slideway 3, four-linkage 4, front connecting plate 5, rear connecting plate 6, screw rod 7, vertical plates on both sides 8, shovel plate 9, slope 10, Lower gap 11, lower convex shaft 12, upper gap 13, upper convex shaft 14, front end face 15, beam surface 16, roller 17, extension spring 18, cleat 19, vertical slide plate 20, bearing pin 21, tire 22.

[0023] Adjustable nailless wheel block comprises anti-skid seat 1, and anti-skid seat 1 bottom surface has a plurality of anti-skid nails 19, can be inserted in the compartment wooden floor surface, plays antiskid effect for iron plate surface. Crossbeam 2 two ends have vertical slide plate 20, and vertical slide plate 20 inserts and slides on the anti-skid seat 1, as respectively having slideway 3 about. Crossbeam 2 is supported by four connecting rods 4 on both sides, and crossbeam 2 is plugged with the upper hinge hole of four connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com