Press

A technology of a press and a workbench, applied in the field of presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

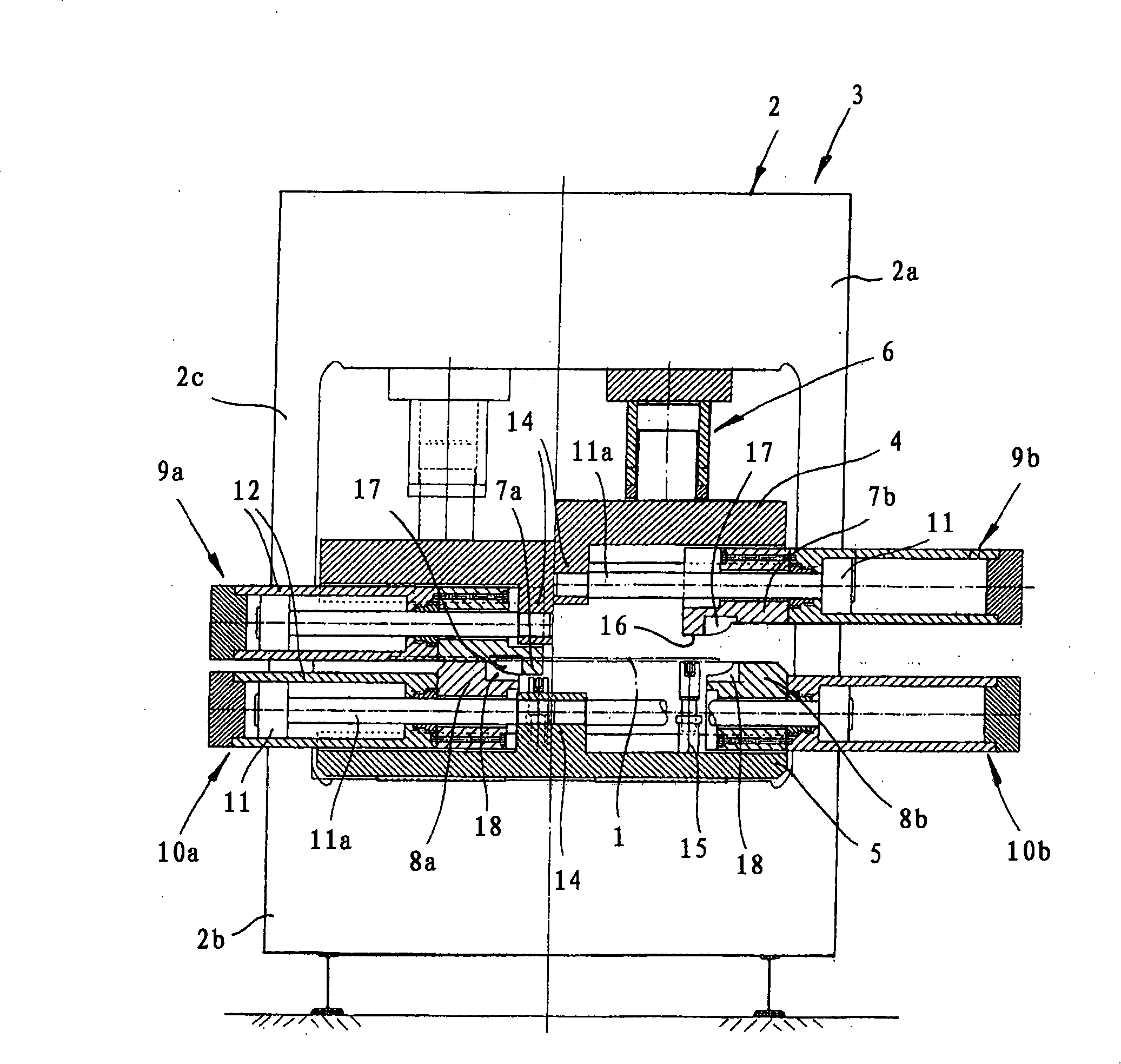

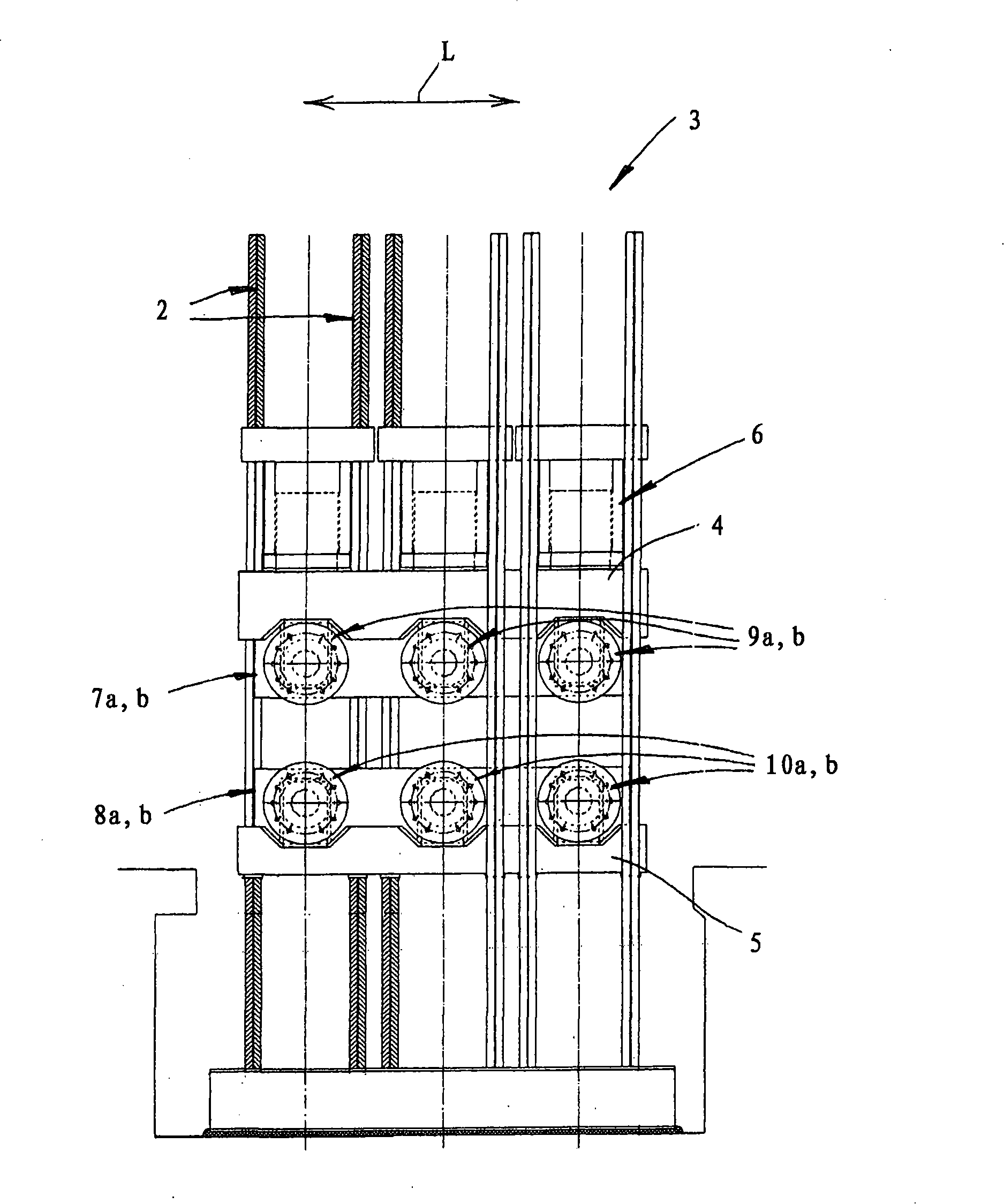

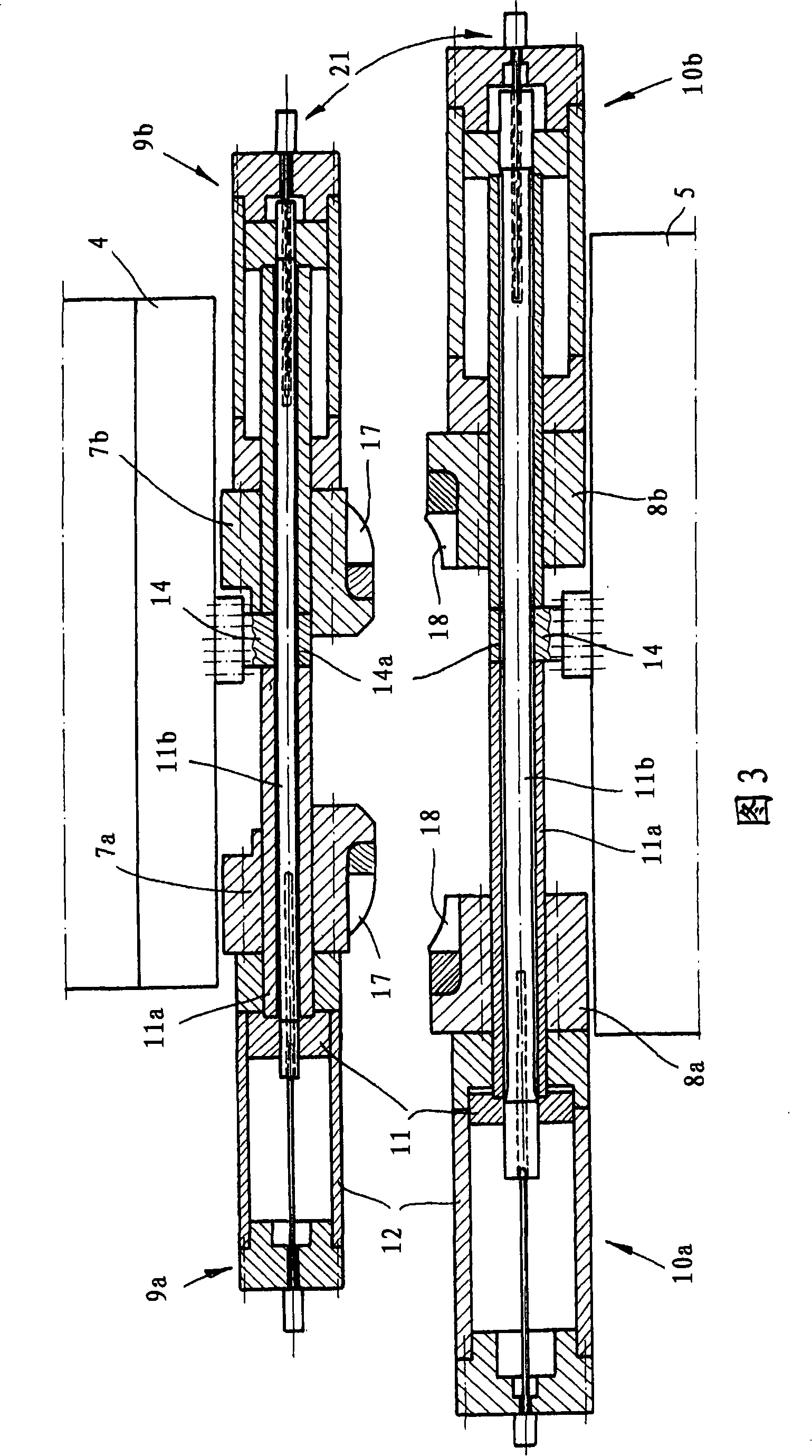

[0025] The figures show a hydraulic press brake or forming press for bending the edges of sheet material. This press is an integral part of the plant for the production of longitudinal seam welded pipes. The press according to the invention is used for bending the longitudinal edges of sheet metal 1 . Typically, the pre-bent sheets are subsequently formed in a U-shaped press and an O-shaped press, and finally welded into pipes. This further processing of the pre-bent sheet metal is not described in detail here.

[0026] The press according to the invention has a press body 3 formed from a plurality of press frames 2 . In addition, the press also has an upper press table 4 and a lower press table 5, wherein a plurality of forming cylinder-piston devices 6 supported on the press frame 2 are mounted on the upper press table 4 or the lower press table. Work on the press table 5. figure 1 with figure 2The shown press according to the invention is implemented as an upper pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com