Hand high-lift operation riser

A high-altitude operation and lifter technology, applied in the direction of hoisting device, clockwork mechanism, etc., can solve the problems of workers falling and dying, unfavorable promotion and use, inconvenient use, etc., to ensure safety performance, light weight, easy to carry and effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

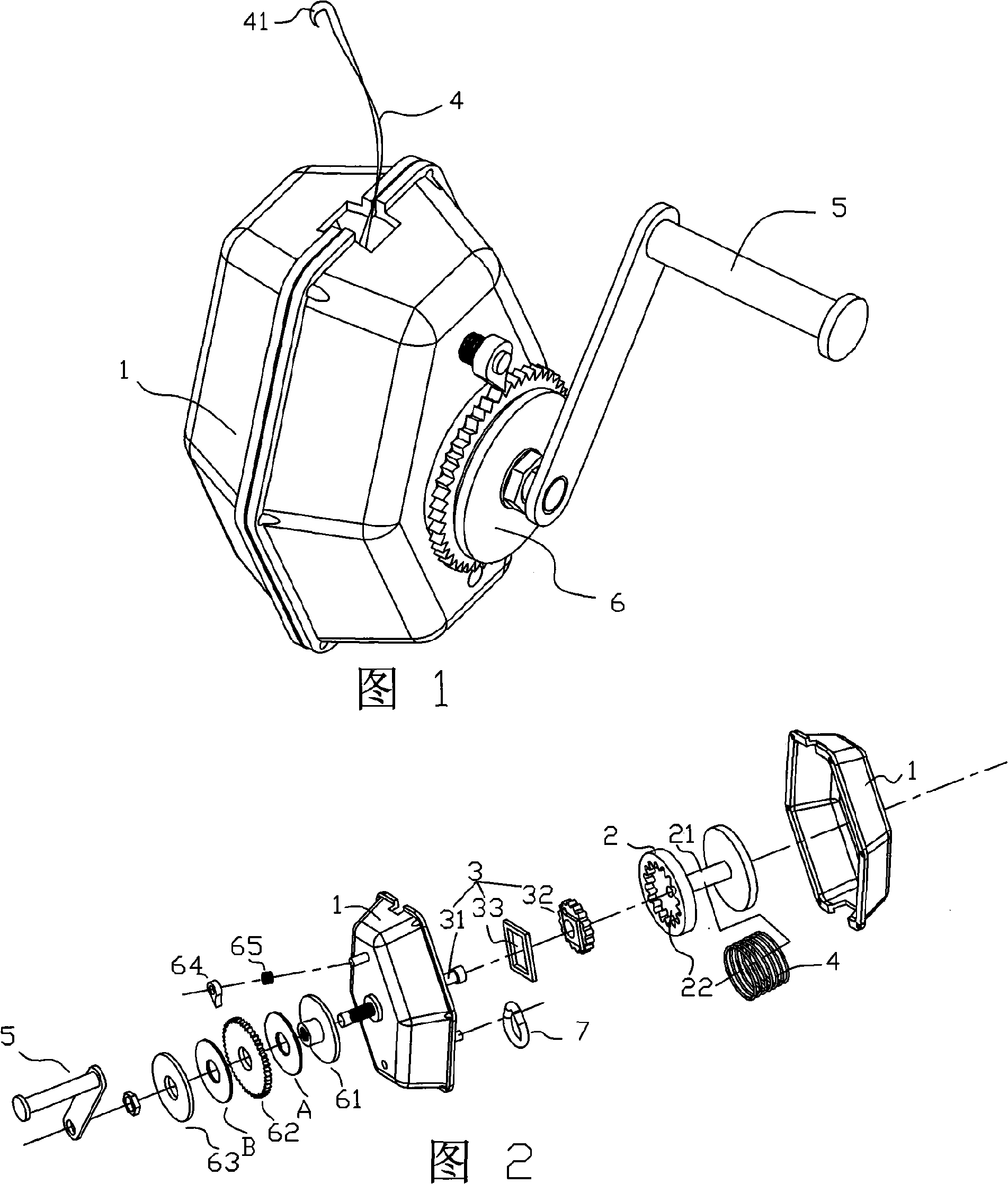

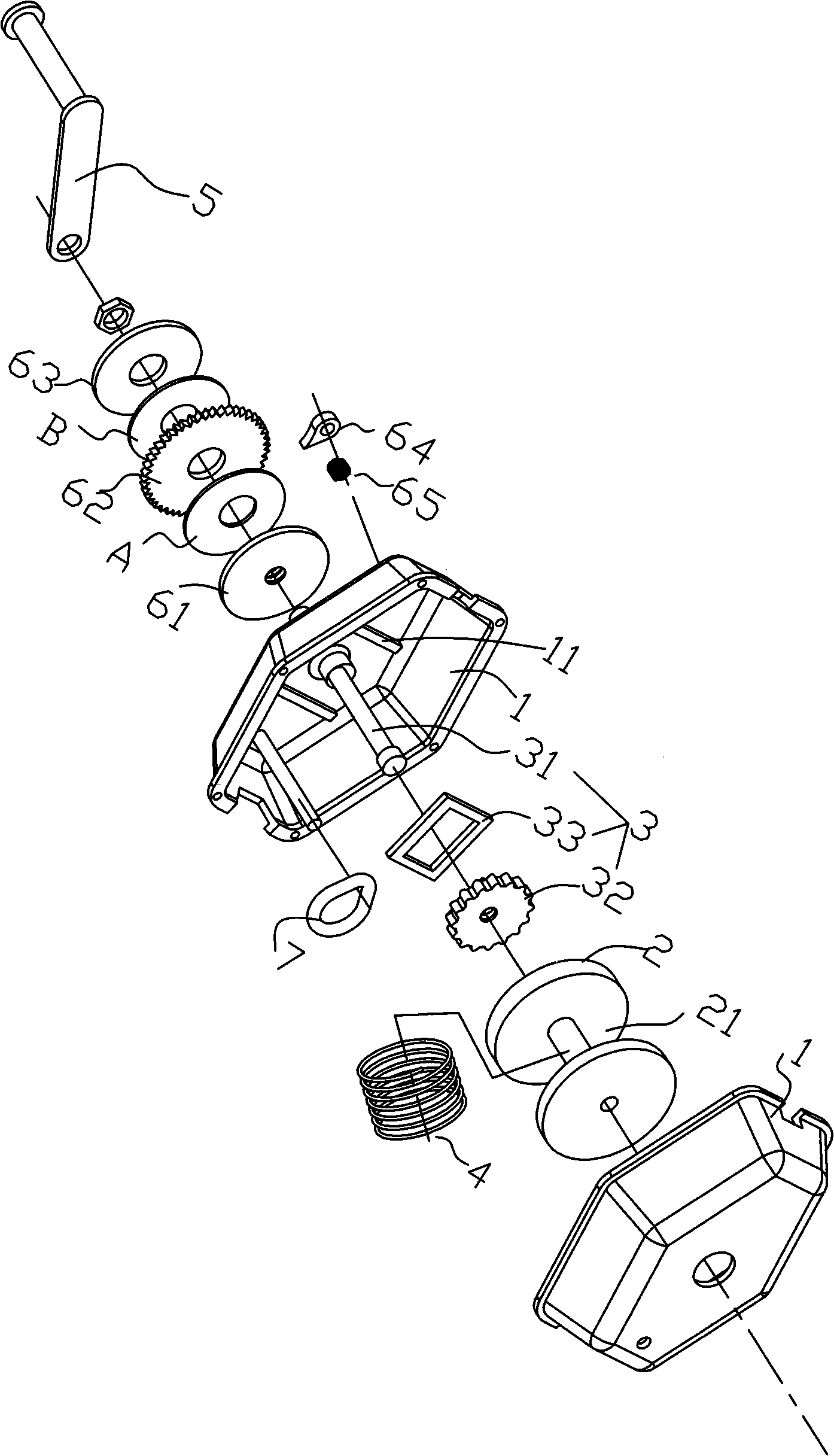

[0018] As shown in Figure 1, a hand-operated lift for aerial work, the whole device includes a housing 1, a reel 2 and a transmission mechanism 3 coaxially connected with the reel.

[0019] As shown in Figures 2 and 3, a groove 21 is set on the reel 2, and the steel cable 4 is wound on the groove 21. When in use, it is only necessary to engage the grab 41 with the fixed hook on the building. At the same time, there is a rotary ring gear 22 on one side of the mandrel 2 .

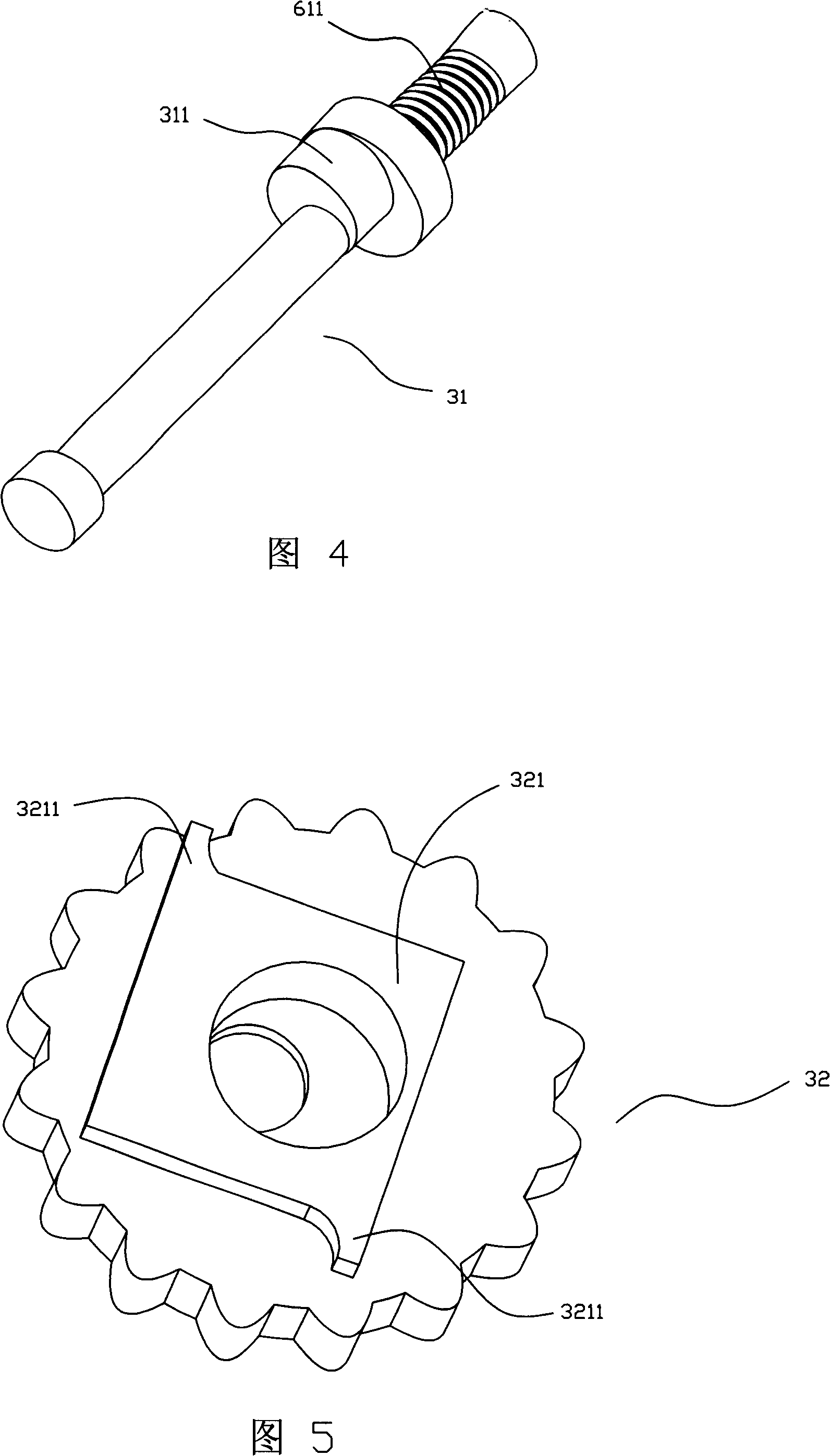

[0020] As shown in Figures 2, 3, 4 and 5, the transmission mechanism 3 includes a stepped transmission shaft 31, one end of the transmission shaft 31 passes through the central hole of the reel 2 and is positioned on the housing 1, and the other end extends out of the housing 1 is connected with hand crank 5. Simultaneously, transmission shaft 31 is provided with an eccentric wheel 311 structure in the middle part, and pinion gear 32 is installed on it, and pinion gear 32 is meshed with the rotary ring gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com