City tunnel shaft type natural ventilation and smoke-discharging proof method

A natural ventilation, smoke prevention and exhaust technology, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., can solve the problems of high cost of equipment maintenance, power consumption, large excavation space, and high tunnel section. The effect of saving construction and operating costs, reducing emission concentration, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

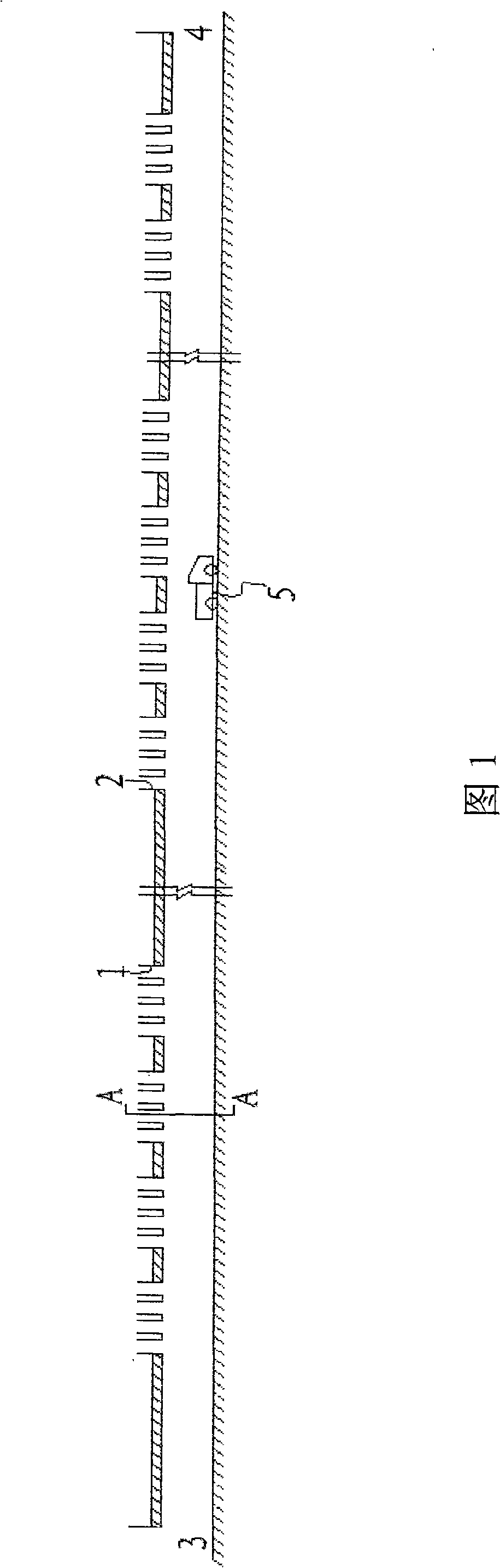

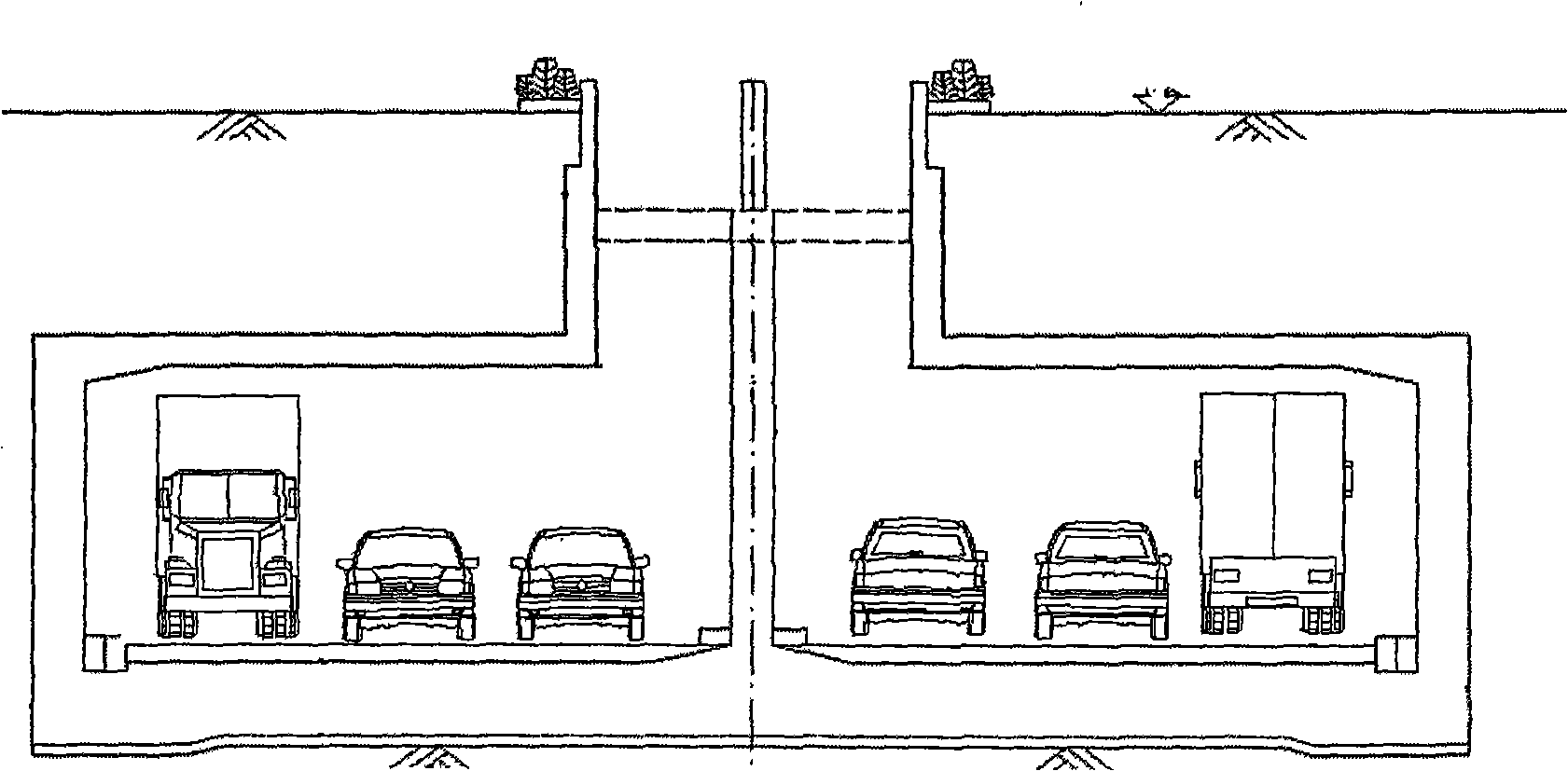

[0029] Referring to Figure 1, the tunnel has two ports, the tunnel entrance 3 and the tunnel exit 4. In practical applications, this technology is still used even if the tunnel has multiple ports. The working principle of the system is the same, only the specific location and number of natural ventilation shafts are set. different.

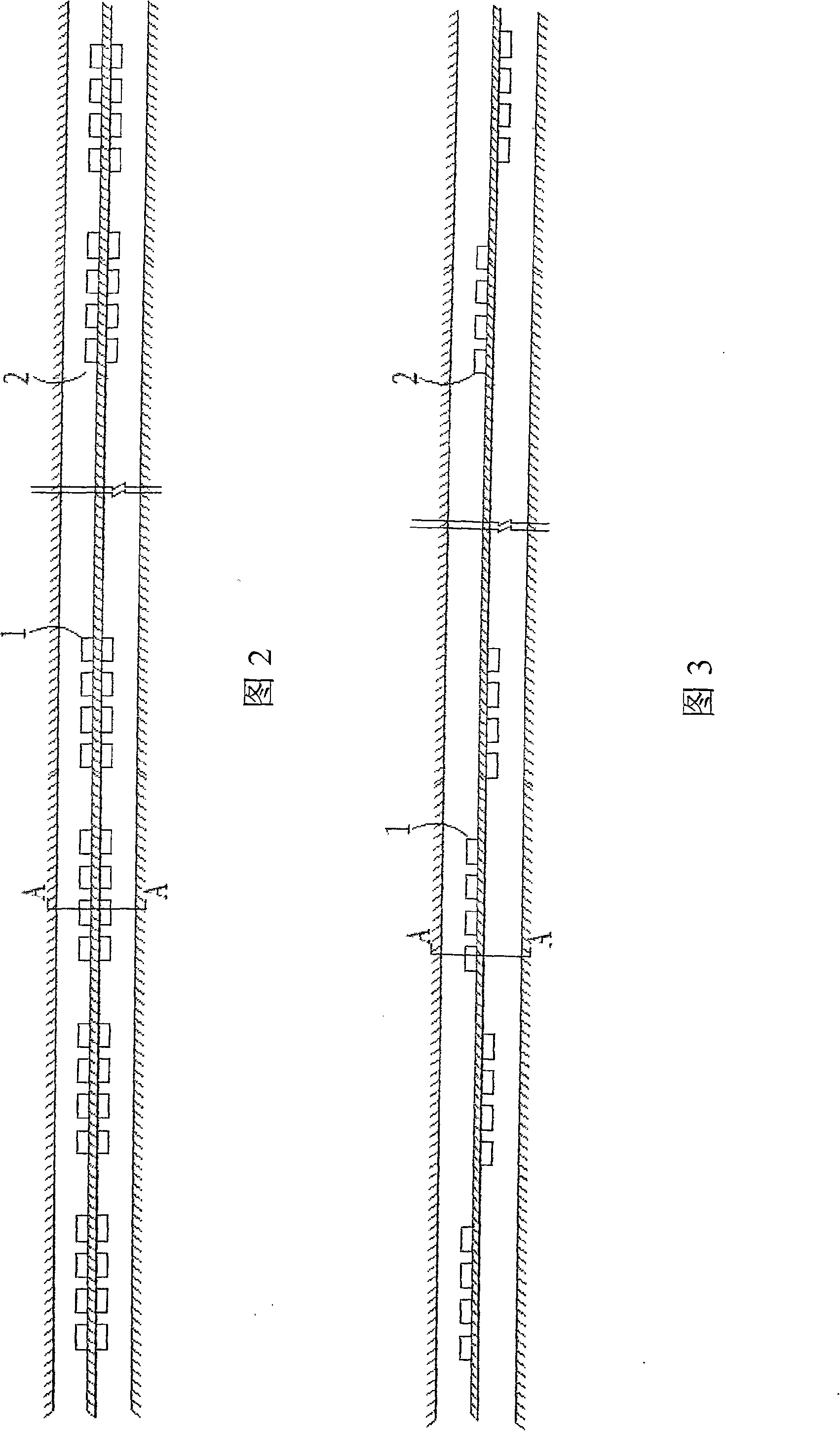

[0030] Set several ventilation shafts on the top or side of the tunnel as required, see shaft 1 and shaft 2 in Figure 1. The ventilation shafts can be set along the entire length of the tunnel, or can be set in sections along the tunnel. The shaft position, cross-sectional shape and area can be changed by common means according to actual conditions, and the maximum distance between shafts should not be greater than 250 meters.

[0031] Referring to Fig. 1, during normal operation, the air in front of the vehicle 5 in the tunnel is squeezed and discharged from the shaft in front of the vehicle 5, and the air behind the vehicle 5 in the tunnel flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com