Spaceflight electronic device excess article automatic detection system and detection method

An automatic detection and electronic device technology, which is applied to the analysis of materials, ultrasonic/sonic/infrasonic generation, instruments, etc., can solve the problems of poor objectivity, low detection accuracy, and inability to judge redundant material characteristics, etc., to achieve detection Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

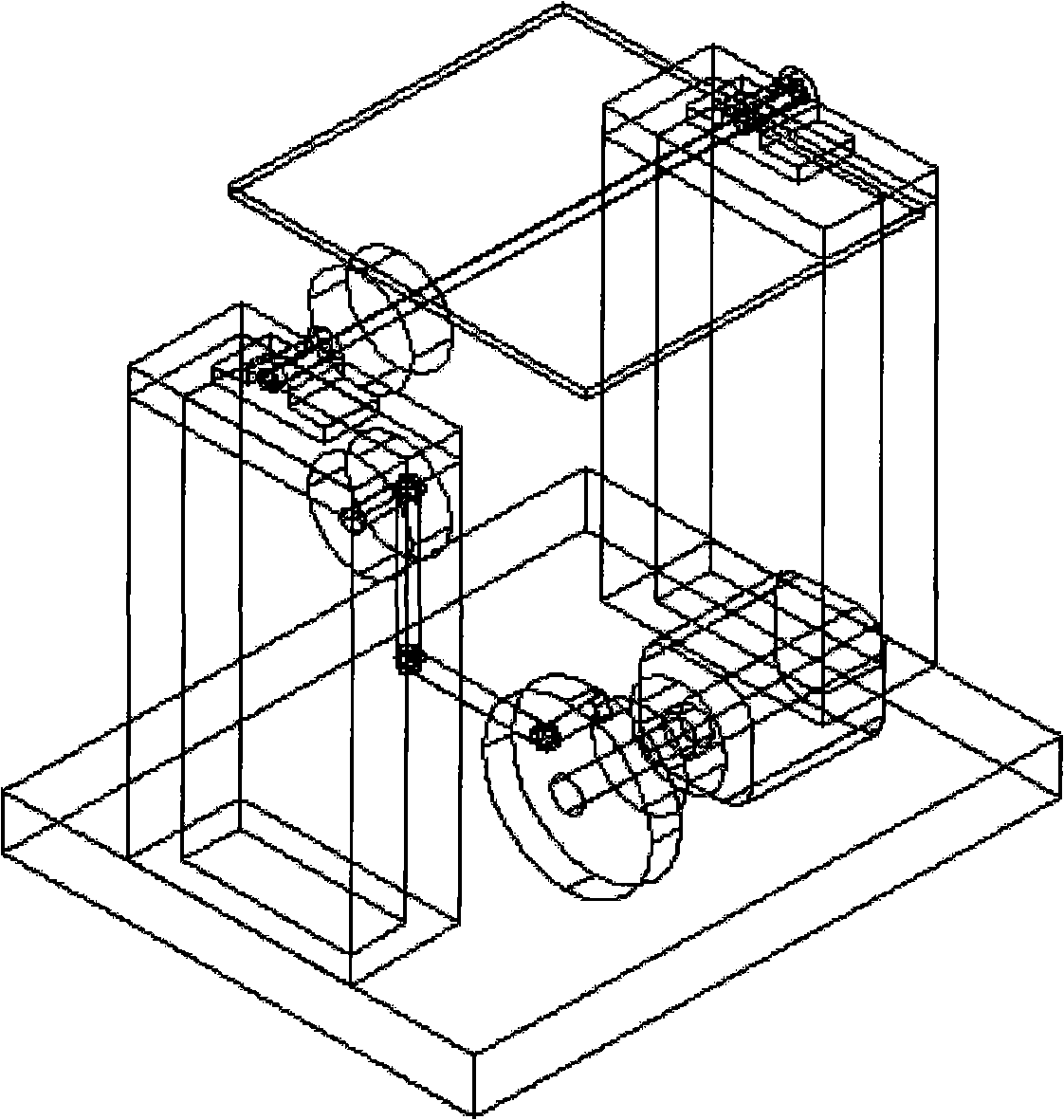

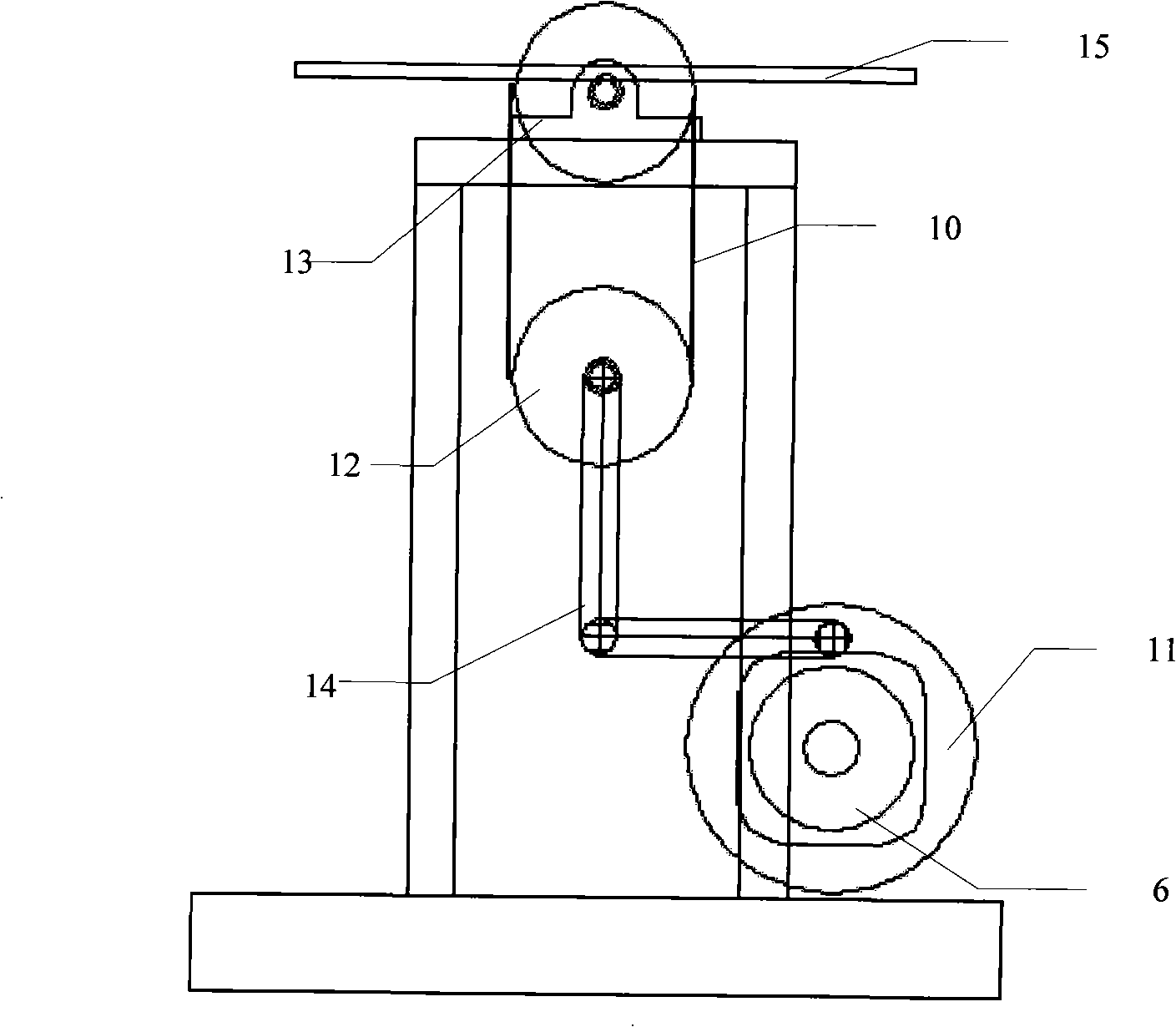

[0044] 1. The mechanical structure design of the turntable

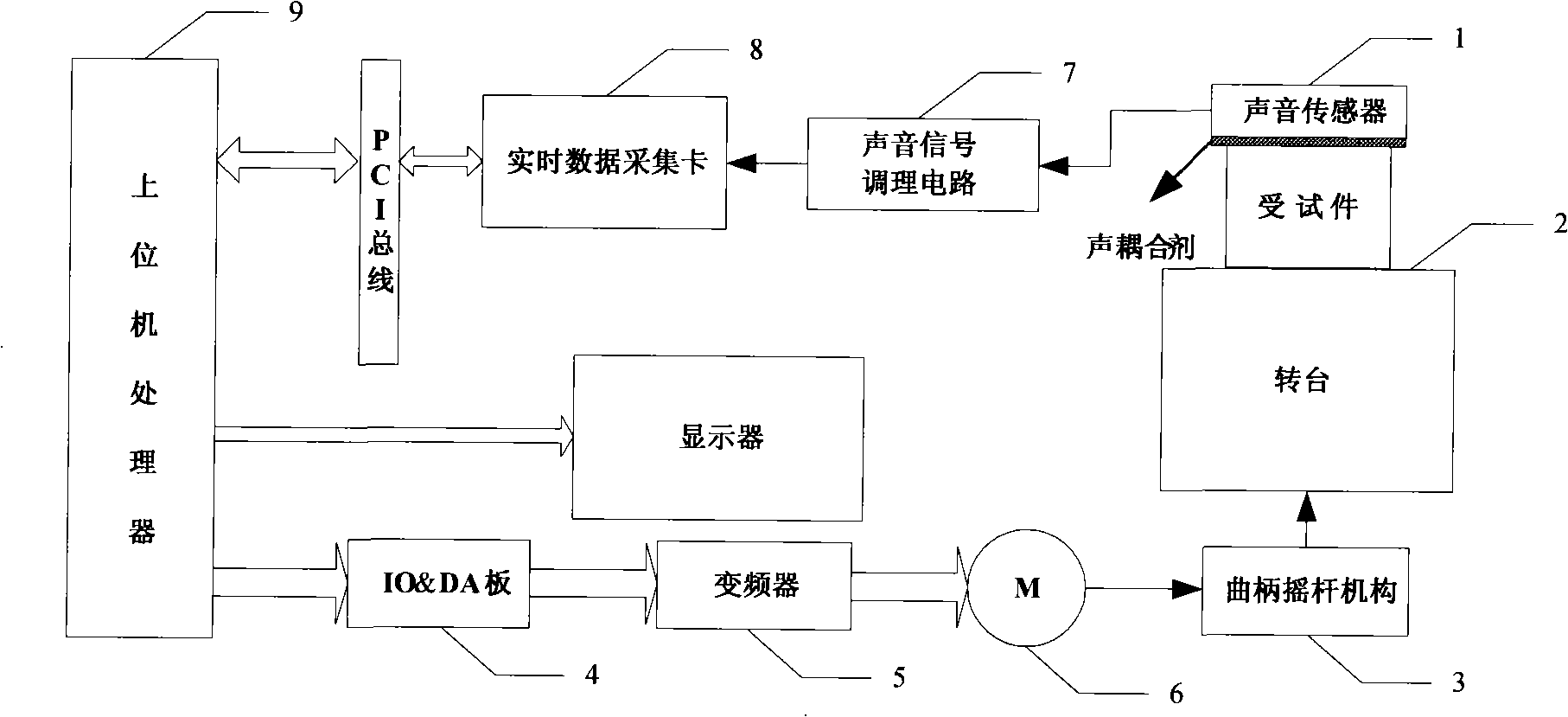

[0045] (1) combination figure 1The system composition of this embodiment includes: sound sensor 1, turntable 2, crank rocker mechanism 3, IO&DA board 4, frequency converter 5, three-phase motor 6, sound signal conditioning circuit 7, real-time data acquisition card 8 and host computer processor 9. The sound sensor 1 is attached to the outer wall of the test piece, and the sound sensor 1 is connected to the signal conditioning circuit 6 through the signal line; the signal conditioning circuit 6 amplifies the signal and outputs it through the PNC plug, and the other end of the data line is input by the DB9 plug; real-time data The acquisition card 8 is inserted into the PCI slot of the upper computer processor 9, and the signal data is sent to the upper computer processor 9 through the PCI ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com