Method for discharging fuel collected container of tank vent system and fuel tank vent system

A technology of ventilation system and collecting container, which is applied in the field of fuel tank ventilation system and motor vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

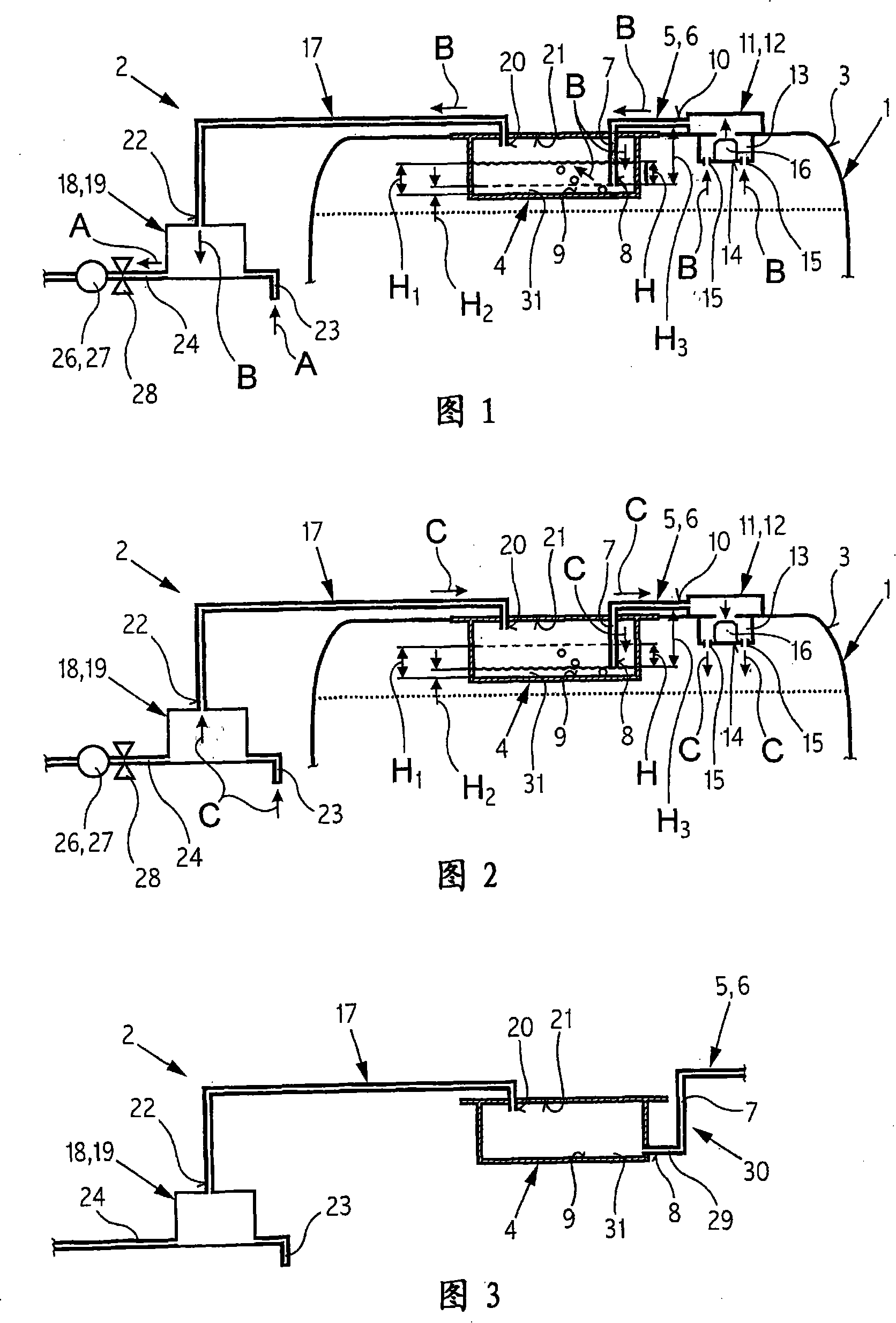

[0023] FIG. 1 shows a schematic diagram of a fuel tank 1 and a tank ventilation system 2 of an internal combustion engine (not shown) of a motor vehicle. The fuel tank ventilation system 2 has an associated fuel collecting container 4 in the upper region 3 of the fuel tank 1 . The fuel collecting container 4 is in flow communication with the fuel tank 1 via a ventilation line 5 . The ventilation duct 5 is designed as an L-shaped ventilation pipe 6, the downcomer 7 of which opens into the interior of the fuel collection container 4 from above and terminates at one end 8 in the bottom area near the bottom plate 9 of the fuel collection container 4 Inside. The other end 10 of the ventilation line 6 , which is opposite the one end 8 , is connected to a valve 12 designed as a float valve 11 for preventing liquid fuel from penetrating into the tank ventilation system 2 . The float valve 11 arranged in the upper region 3 of the tank 1 has a buoyancy chamber 13 which has an opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com