Monitoring Method of Internal Corrosion in Gas Transmission Pipeline

A gas pipeline and internal corrosion technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as inability to obtain monitoring results, complex equipment structure, and limited use methods, and achieve monitoring operations. The method is flexible and efficient, the measurement result is accurate, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

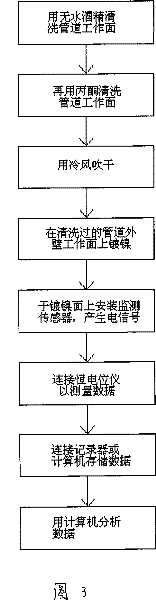

[0027] The method for monitoring internal corrosion of gas pipelines is characterized in that: the following steps are carried out sequentially:

[0028] ① Select the working point of the carbon steel gas pipeline to be measured and perform pretreatment.

[0029] Prepare the nickel plating liquid used for nickel plating, and its components are: 1 part of nickel sulfate, 0.18 part of nickel chloride, and 0.16 part of boric acid.

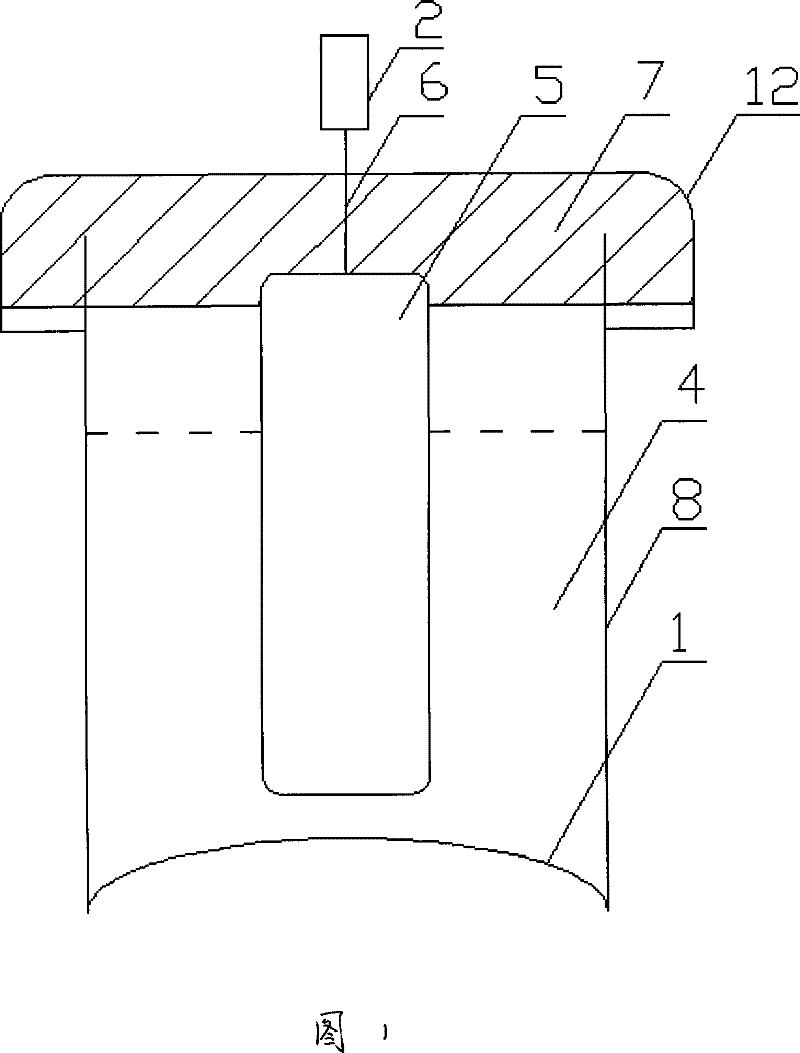

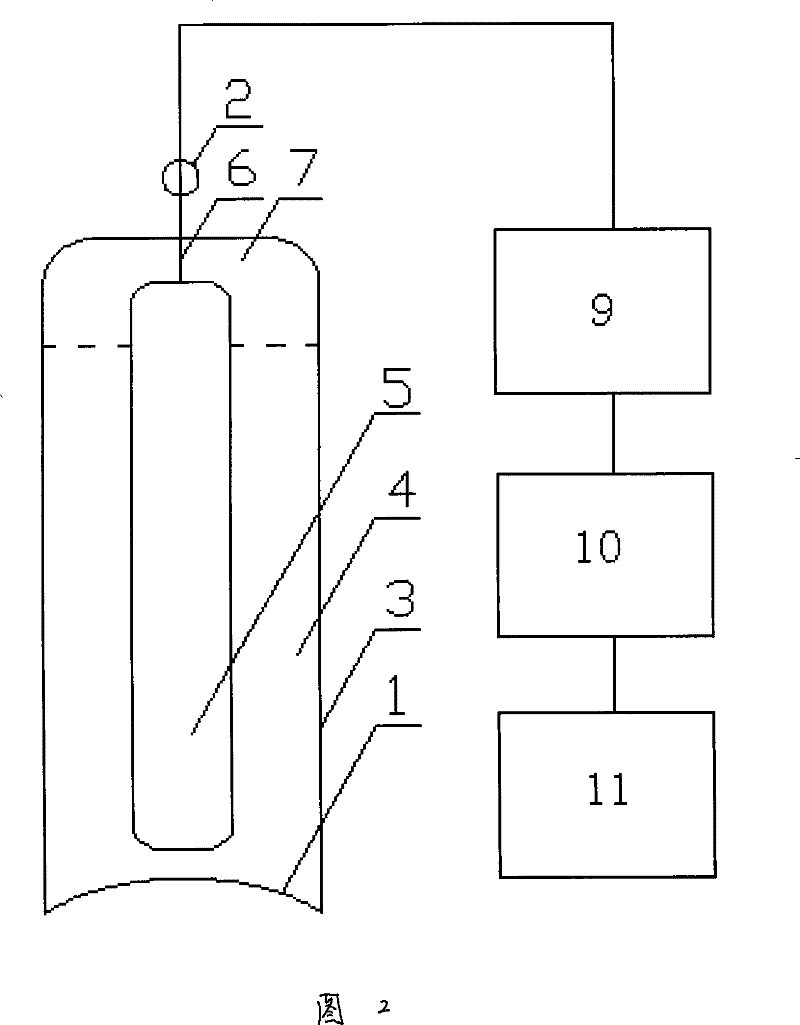

[0030] Clean the selected working surface on the outer wall of the pipeline with absolute alcohol, then clean it with acetone, and dry it with cold air, and then use the nickel plating solution to plate nickel on the working surface to form a nickel-plated layer on the outer wall of the pipeline to be tested. The detection working surface is to use the nickel-plated detection working surface as an external electrode of the sensor;

[0031] ②The monitoring sensor is pre-assembled completely, and then fixedly installed on the detection working surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com