Capacitance type gas sensor based on carbon nano-tube array and preparing method thereof

A carbon nanotube array and gas sensor technology, applied in the field of gas detection and nano-sensors, can solve the problems of large distance between flat electrodes, small capacitance value, low change sensitivity, etc., and achieve the effect of long service life, shortened distance, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

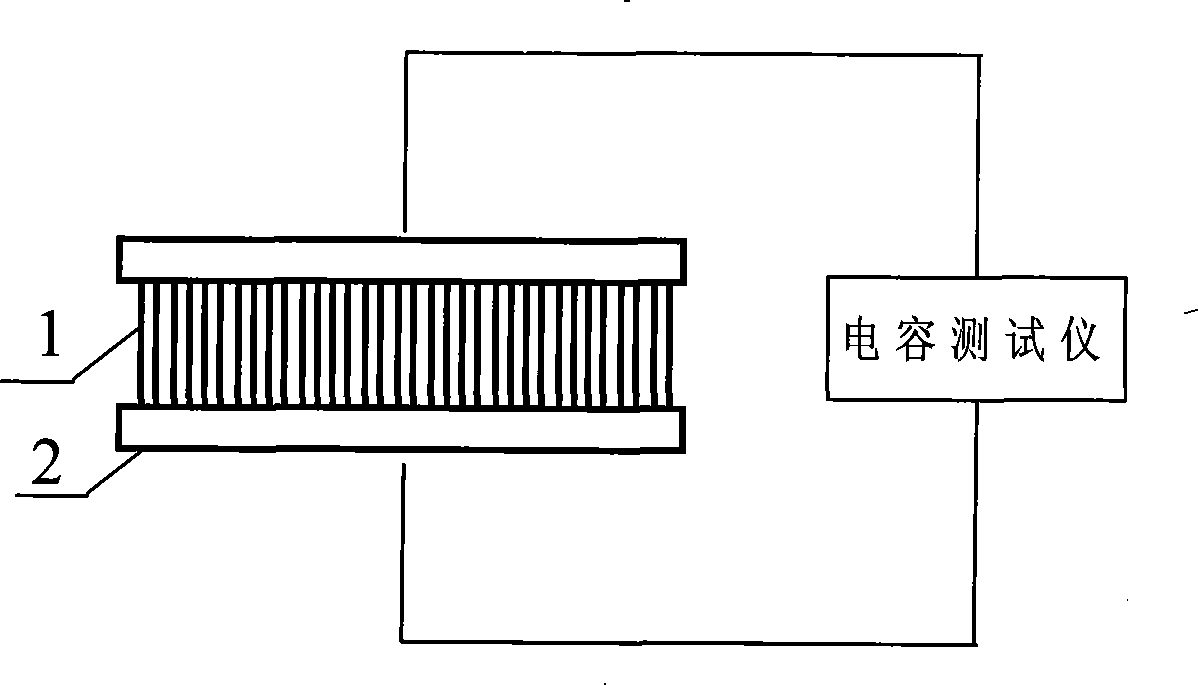

Method used

Image

Examples

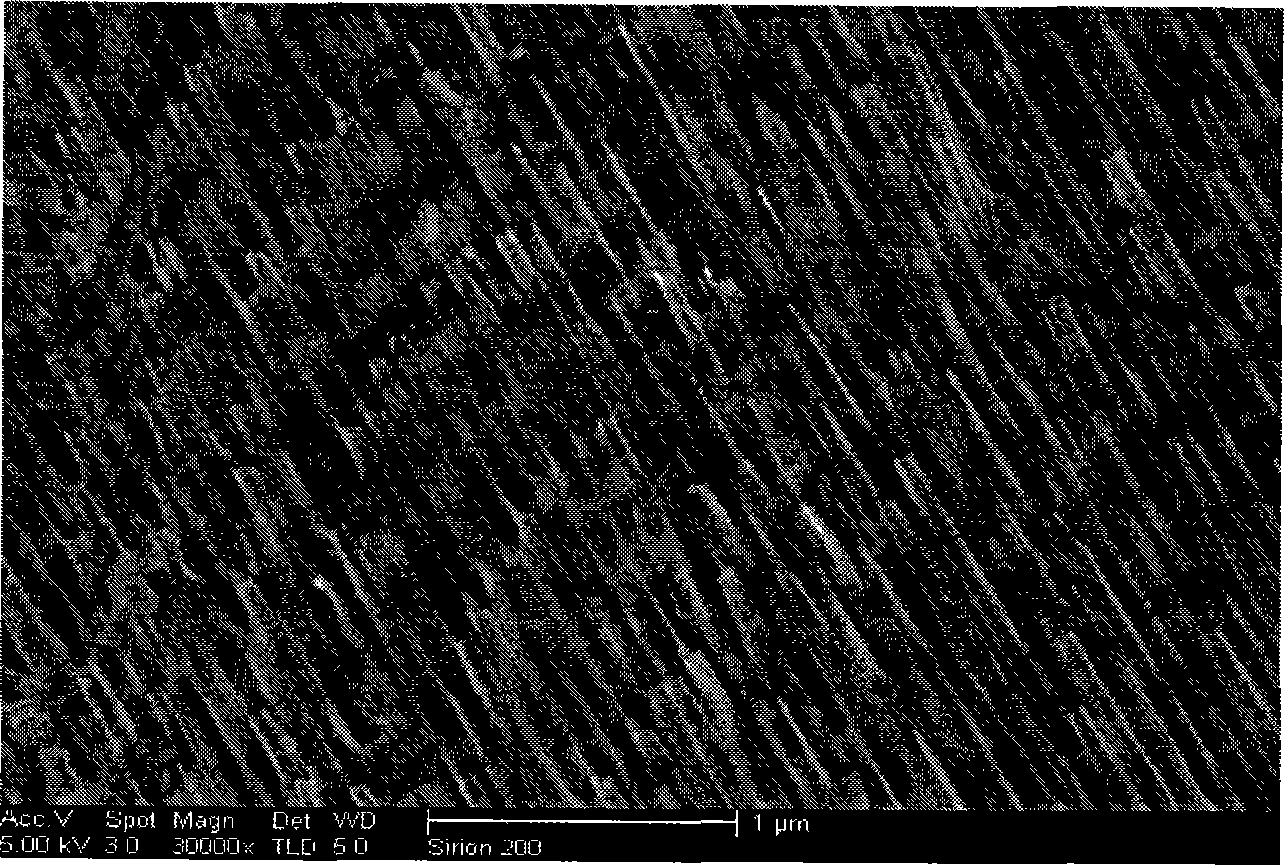

Embodiment 1

[0032] The aluminum oxide template was prepared by the secondary oxidation method, and the preparation process was as follows: after the aluminum sheet was cleaned with an organic solvent, it was annealed at 500° C. for 4 hours in nitrogen, and cooled naturally. The annealed aluminum sheet was ultrasonically cleaned with acetone, and electropolished in a polishing solution (the volume ratio of absolute ethanol to perchloric acid was 9:1). Carry out primary anodic oxidation to polished aluminum sheet, electrolytic solution is the oxalic acid solution of 0.3M, primary oxide layer is removed with the mixed acid solution of phosphoric acid (6wt%) and chromic acid (1.8wt%), then in the same condition as primary anodic oxidation Secondary anodic oxidation is carried out under certain conditions. After secondary oxidation, use saturated tin tetrachloride solution to remove the aluminum on the back, and then use phosphoric acid to expand the pores. Finally, it is washed and dried to ...

Embodiment 2

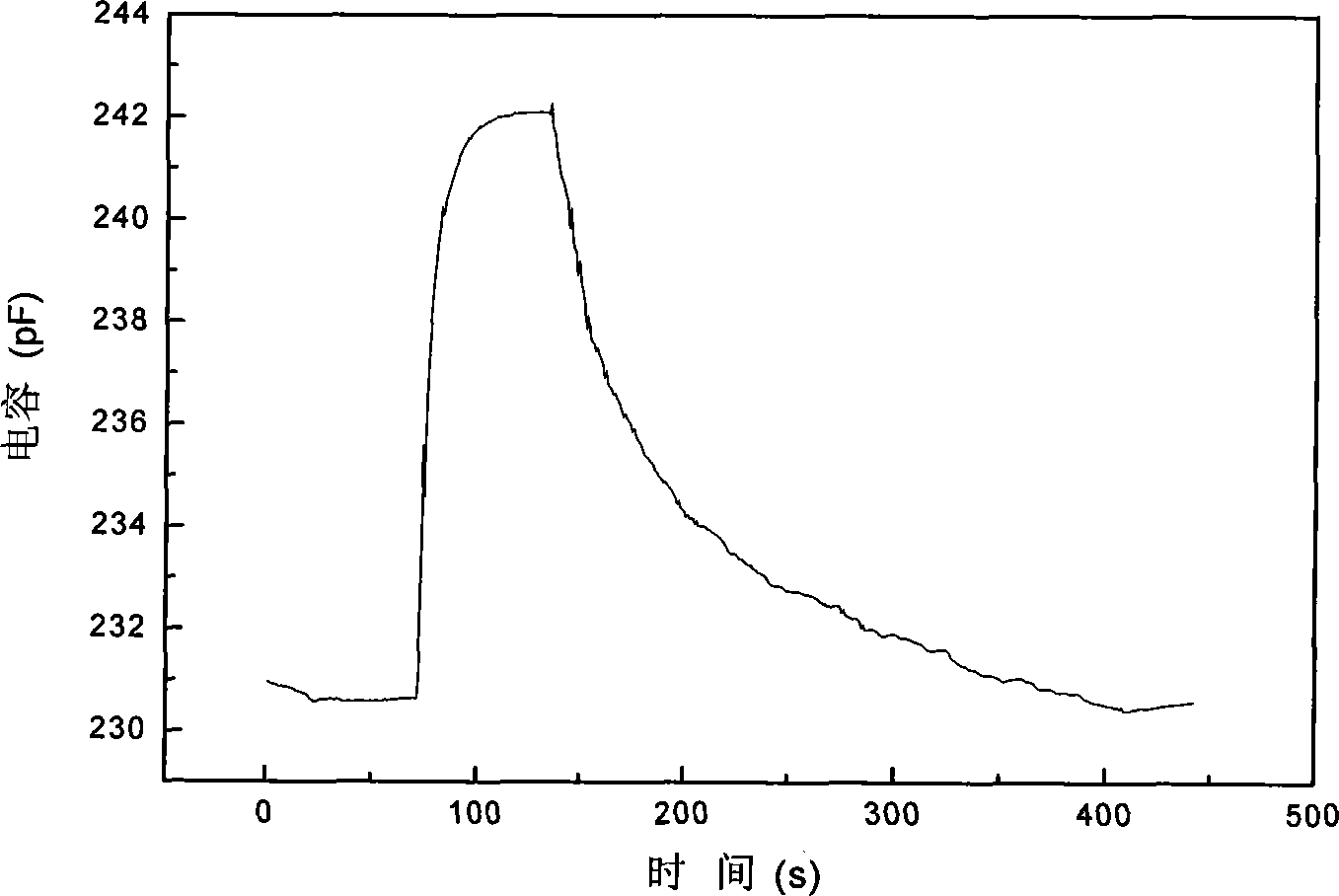

[0036]A capacitive gas sensor based on a carbon nanotube array is used to test ammonia. The capacitive gas sensor is placed in a 1-liter container, and a certain volume of ammonia gas is injected into the test box with a syringe. When the response of the capacitive gas sensor to ammonia reaches the maximum value, the gas in the test box is emptied, and then inject different volumes of ammonia gas. After repeated tests, the obtained Figure 6 The capacitance change curve of the capacitive gas sensor for different test volumes of ammonia gas is shown. From Figure 6 It can be seen that the capacitive gas sensor based on carbon nanotube array has high sensitivity and still has a good response to 0.1ml of ammonia gas (about 1ppm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com