Hand electric tool machine

A power tool, hand-held technology, applied in the field of hand-held power tools, can solve the problems of hand grinding and insecurity, and achieve the effect of safe replacement, convenient and quick removal and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

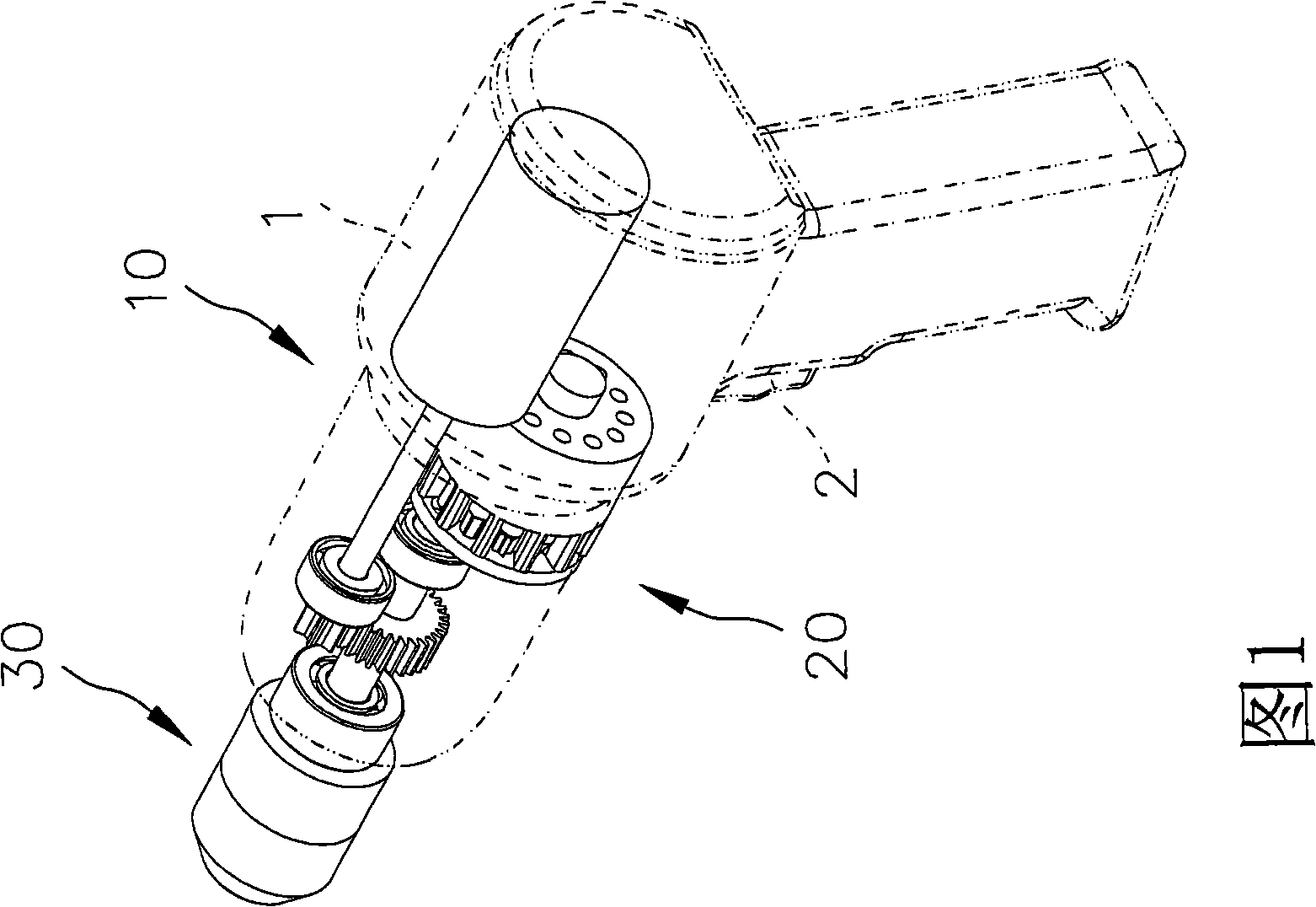

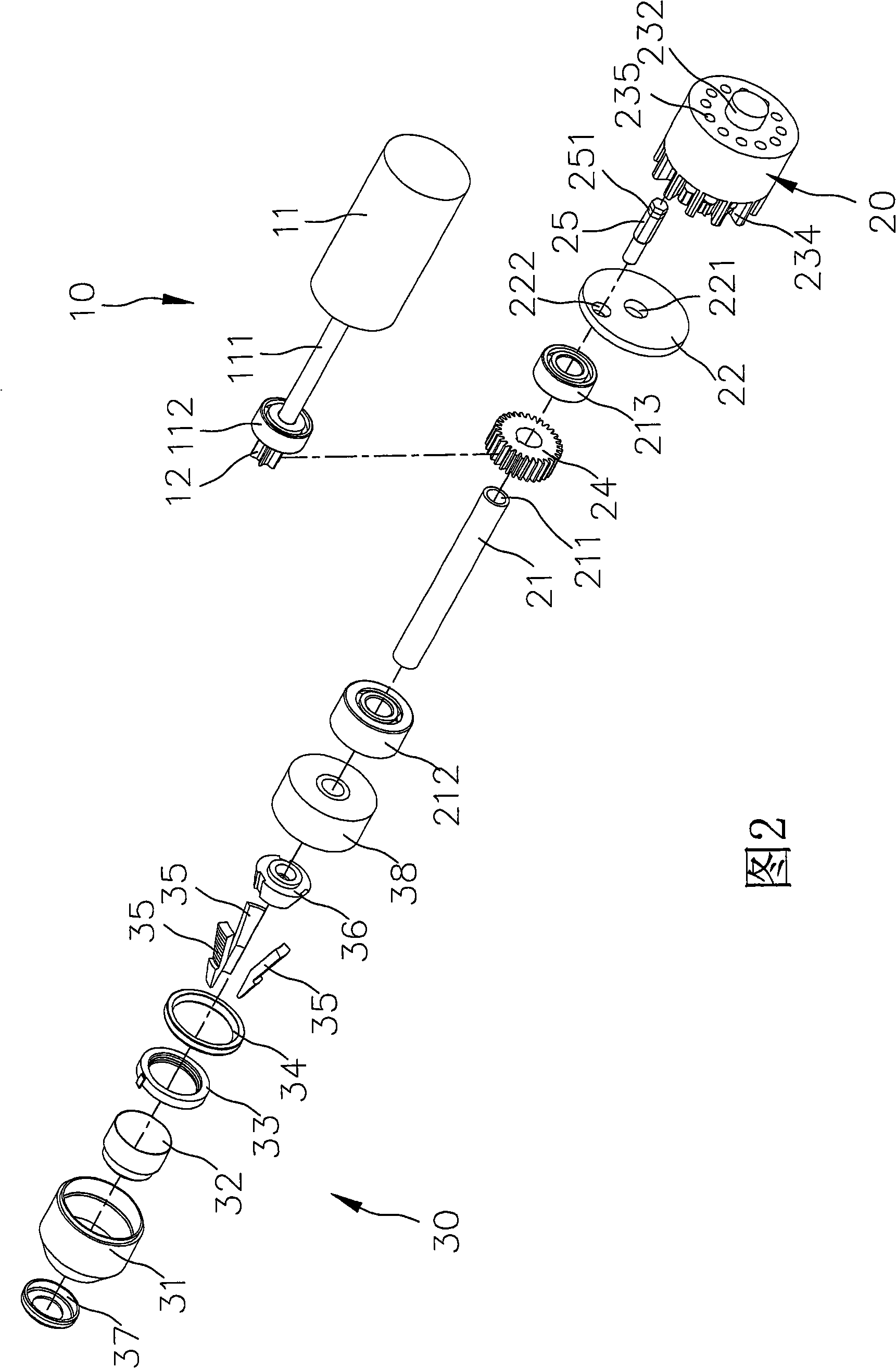

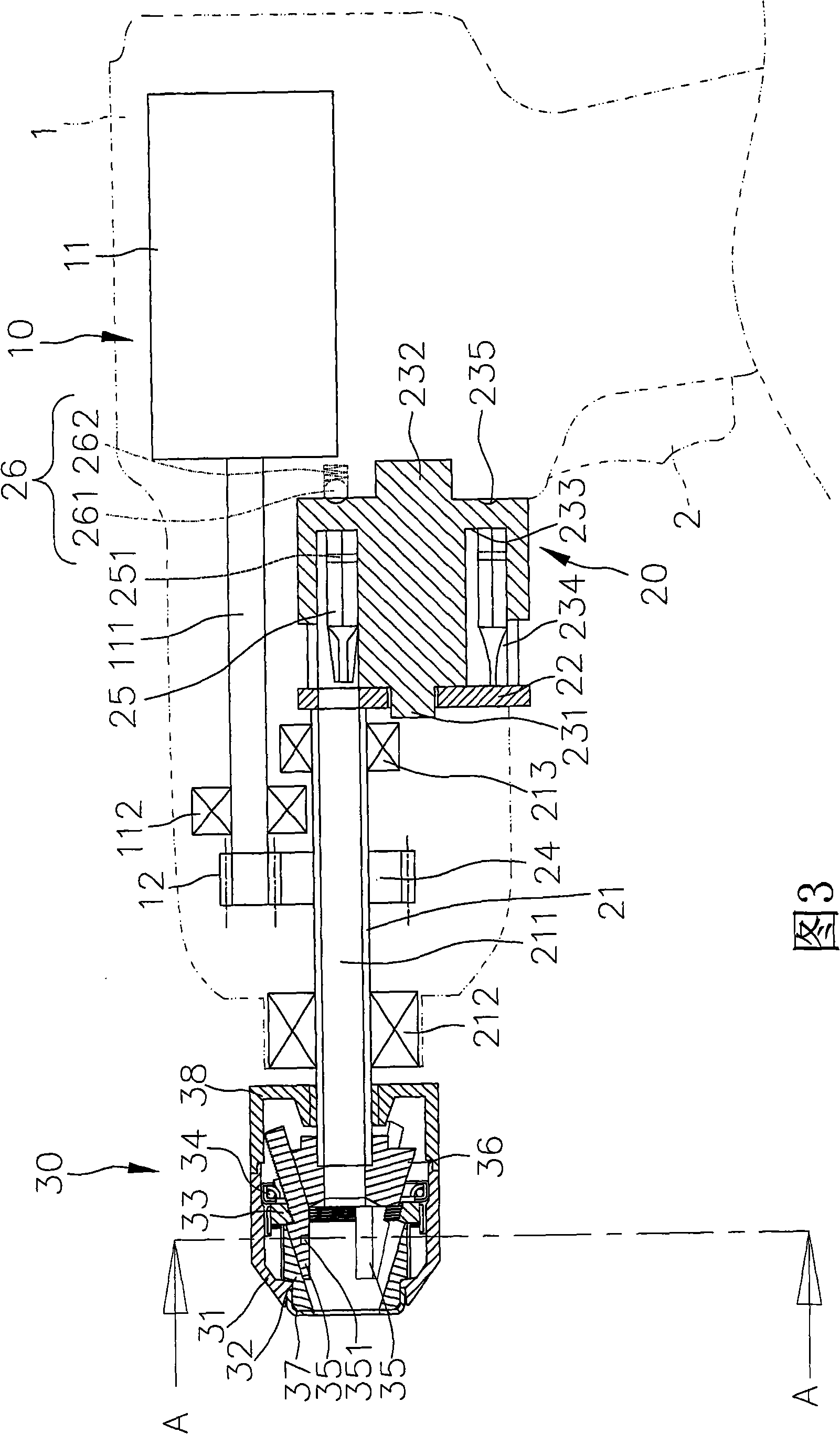

[0025] As shown in Figures 1 to 13, the hand-held power tool of the present invention (such as a hand electric drill) includes a housing body 1, a driving device 10, a collet device 30, a hollow power shaft 21 and a tool head storage device 20, wherein the driving device 10 is installed Set in the housing main body 1 for generating power; the chuck device 30 is installed on the front end of the housing main body 1 for clamping the tool head 25; the hollow power shaft 21 is connected to the driving device 10, and the driving device 10 Drive to rotate, and the hollow power shaft 21 has a hollow cavity 211 that passes through from the front end to the rear end, the front end of the hollow power shaft 21 is fixed in the chuck device 30; the tool head storage device 20 is rotatably supported on the housing body 1, It also has a plurality of tool bit storage slots 233, and the rear end of the hollow power shaft 21 communicates with one of the tool bit storage slots 233, and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com