Slipping process of large tonnage pressure frame

A large tonnage and slippage technology, used in presses, manufacturing tools, etc., can solve the problems of no hoisting equipment and the inability of large hoisting equipment to perform, and achieve the effect of stable and reliable travel, material saving, and convenient disassembly.

Active Publication Date: 2008-10-15

CHINA 22MCC GROUP CORP

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, more and more large-scale equipment is being transported, but the workshop not only does not have the corresponding hoisting equipment, but also because the workshop is closed, the large-scale hoisting equipment cannot display its capacity, so how to transport the oversized and overweight equipment to the workshop and install it in place is difficult. became a problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

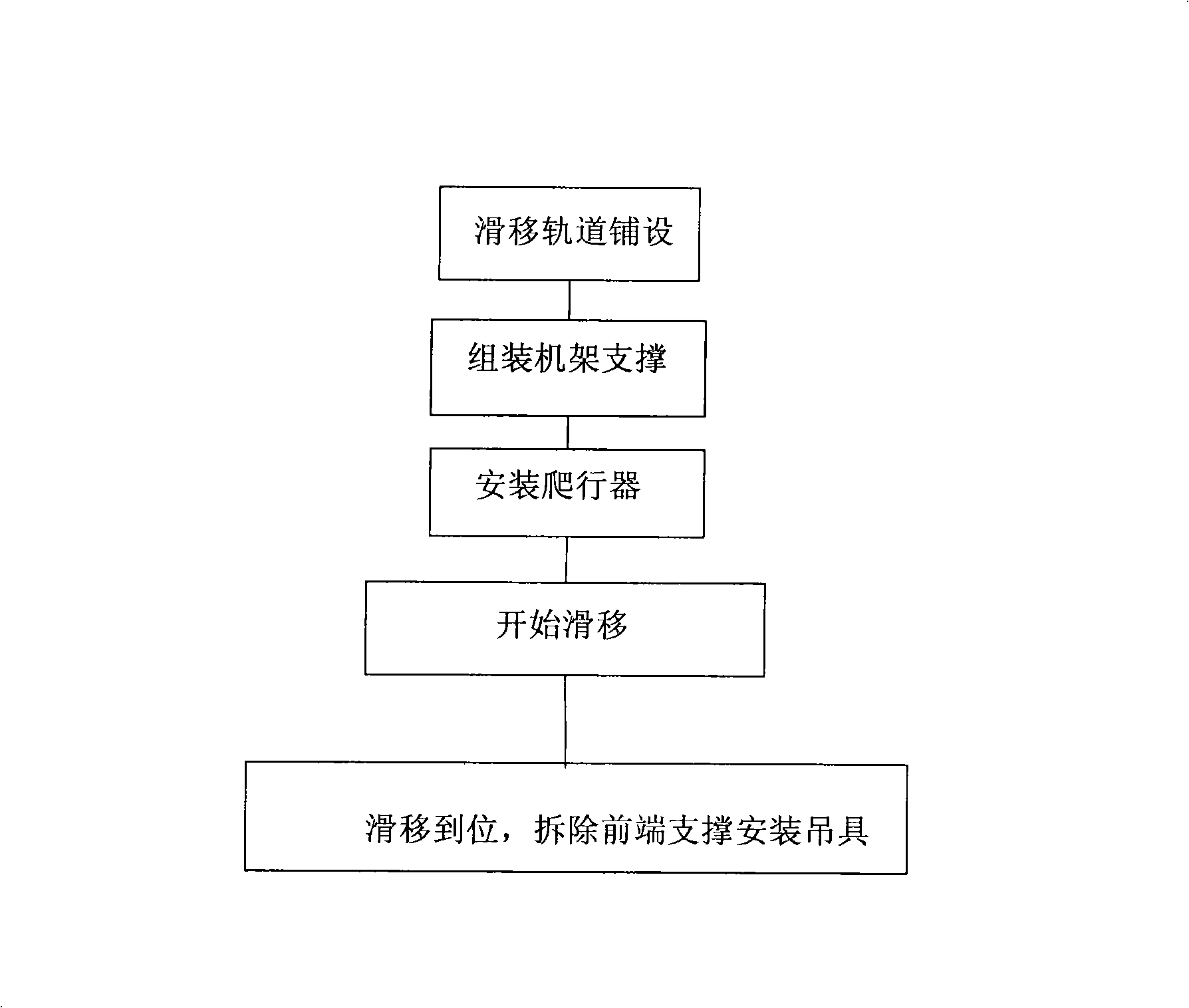

The invention relates to a method of construction and installation for large scale equipment, in particular to a sliding method of a pressing machine frame with large tonnage. The method comprises the following steps: laying a slide-used steel plate face and a slide-used track; assembling a machine frame support; installing a hydraulic sliding tool; starting sliding; and disassembling an installation hanger on the front end support after sliding in place. The method has the advantages as follows: the bracing frame passes through the pressing machine frame for the interior bracing and fixing, so that the pressing machine frame is fixed more stably and safely; the material is saved; the length of a rotating shaft of a joist is adjustable, larger or smaller pressing machine frames can also be utilized, the universality is strong and the cost is saved; the joist and a bracket adopt split-type structure, the disassembly is convenient and the efficiency is greatly improved; a hydraulic crawl device pushes the bracing frame to slide, the travel is stable and reliable; the number and the height of the sliding bracing frame is adjustable, thereby being applicable to pressing machine frames with various weights and specifications and other devices; the construction period is greatly reduced, so that the safety is guaranteed; and the method is suitable for the hoisting installation exercises in narrow spaces or high altitude, underground, and other construction situations.

Description

Ground Sliding Method of Large Tonnage Press Frame Technical field: The invention relates to a construction and installation method for large-scale equipment, in particular to a sliding method for a large-tonnage press frame. Background technique: At present, more and more large-scale equipment is being transported, but the workshop not only does not have the corresponding hoisting equipment, but also because the workshop is closed, the large-scale hoisting equipment cannot display its capacity, so how to transport the oversized and overweight equipment to the workshop and install it in place is difficult. became a problem. Invention content: In order to solve the above problems, the present invention provides a sliding method for a large-tonnage press frame. The method of lifting the equipment sideways and hydraulically pushing it on the slideway makes it possible to transport thousands of tons of equipment inside the workshop, making the transportation of large compo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B30B15/04

Inventor 万以明刘瑄梁新平鲁福利孙富

Owner CHINA 22MCC GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com