Additional weight hoisting method

A hoisting and counterweight technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve problems such as fragile products, safety incidents, time-consuming, etc., and achieve the effect of enhancing safety factor, improving installation quality, and widely promoting value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

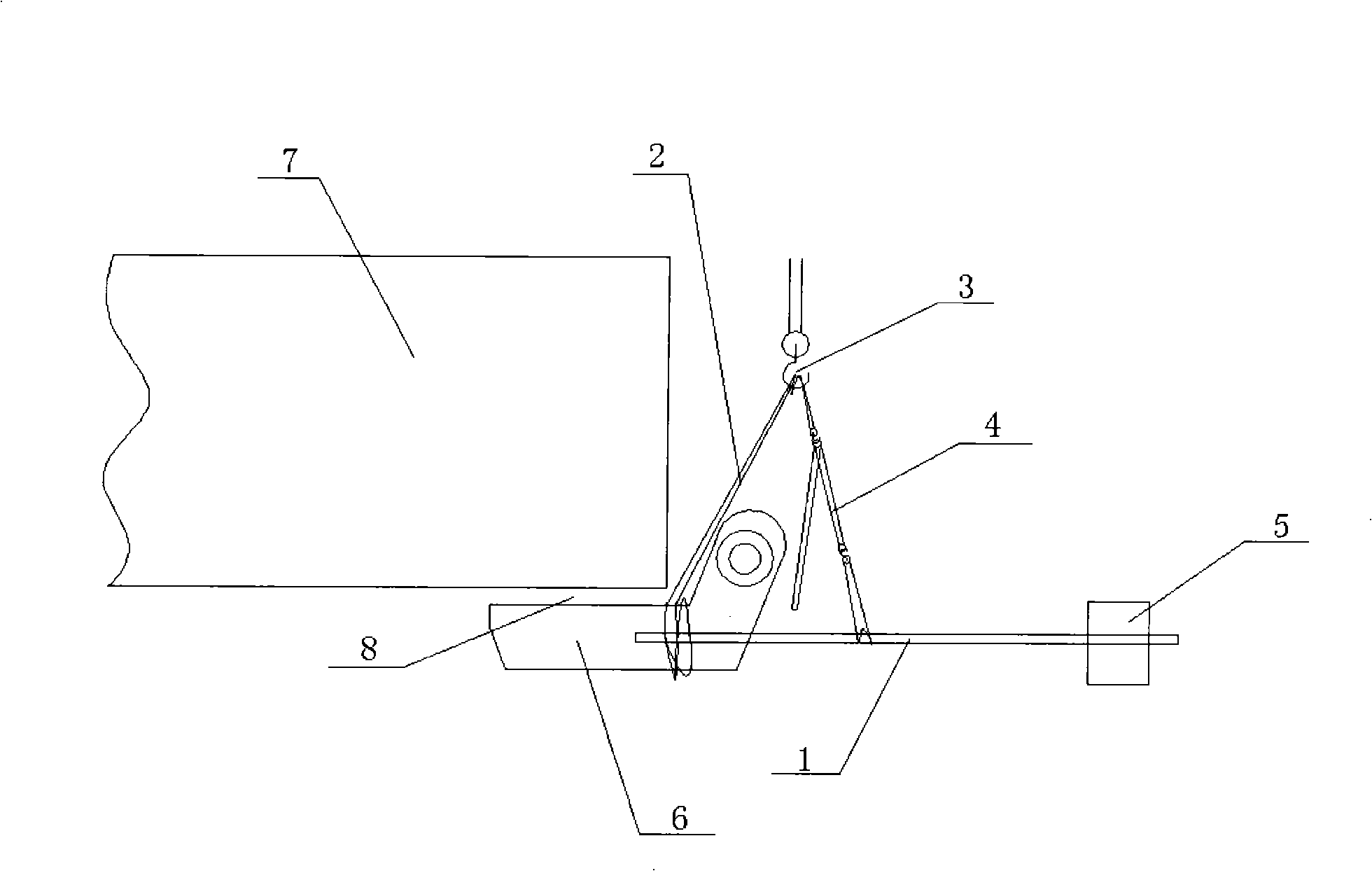

[0019] Such as figure 1 Shown is a schematic diagram of a counterweight hoisting method in Embodiment 1, and any rope operator of a crane can use it freely through simple training of the present invention.

[0020] The transportation of large-scale generators with a weight of more than 300 tons depends on D35 or D38 clamp-type railway transport vehicles in part. Among them, the installation of the object 6, that is, the vehicle accessories, is difficult, and it must be installed in a large generator with a weight of more than 300 tons. Generator base 7 bottoms 8 are installed four objects 6 and are vehicle accessories, and each object 6 is vehicle accessories and weighs 4 tons.

[0021] If according to the traditional installation method, object 6 i.e. the vehicle accessories are placed on the ground position earlier, then the large-scale generator support 7 of more than 300 tons is lifted to the pre-placed object 6 i. The micro-adjustment of the trolley and the trolley is al...

Embodiment 2

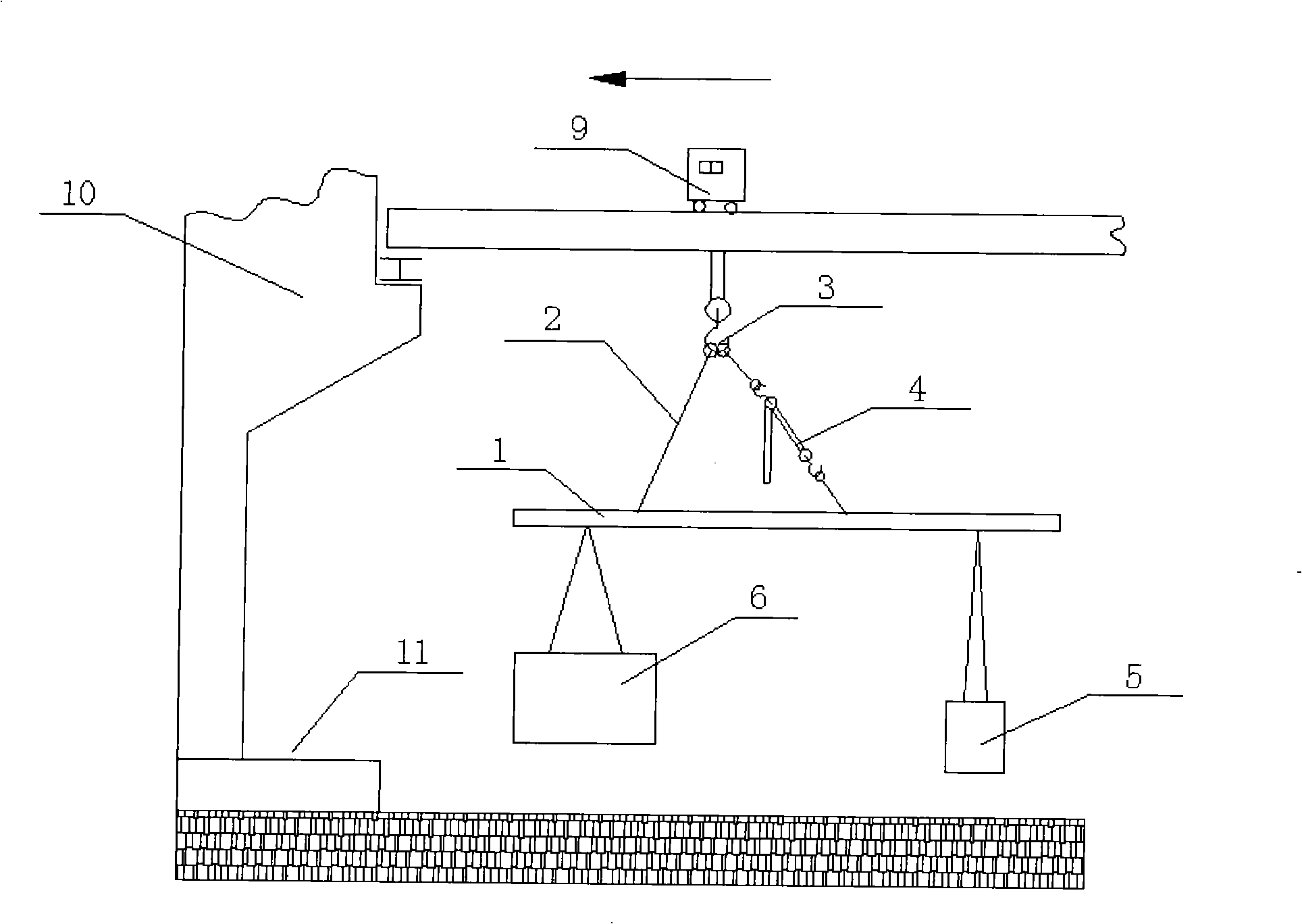

[0025] At the production site, there are many objects under the track of the bridge crane. According to the rules and regulations, the bridge crane cannot be directly used for crooked lifting. This problem can be solved by using the present invention. Such as figure 2 As shown, it is a schematic diagram of a method for counterweight hoisting in Embodiment 2:

[0026] The production workshop has an object 6 weighing 4 tons, that is, a transformer. In order not to occupy the effective operating area of the production workshop, it is generally installed at the position 11 below the load-bearing column of the workshop.

[0027] Object 6 is the installation project of the transformer. The traditional installation method is to place a set of roller bars under the transformer, and then use a hoist to drag it to the installation location, which is time-consuming, laborious and inefficient.

[0028] The production workshop has a bridge crane 3 with a rated lifting capacity of 20 to...

Embodiment 3

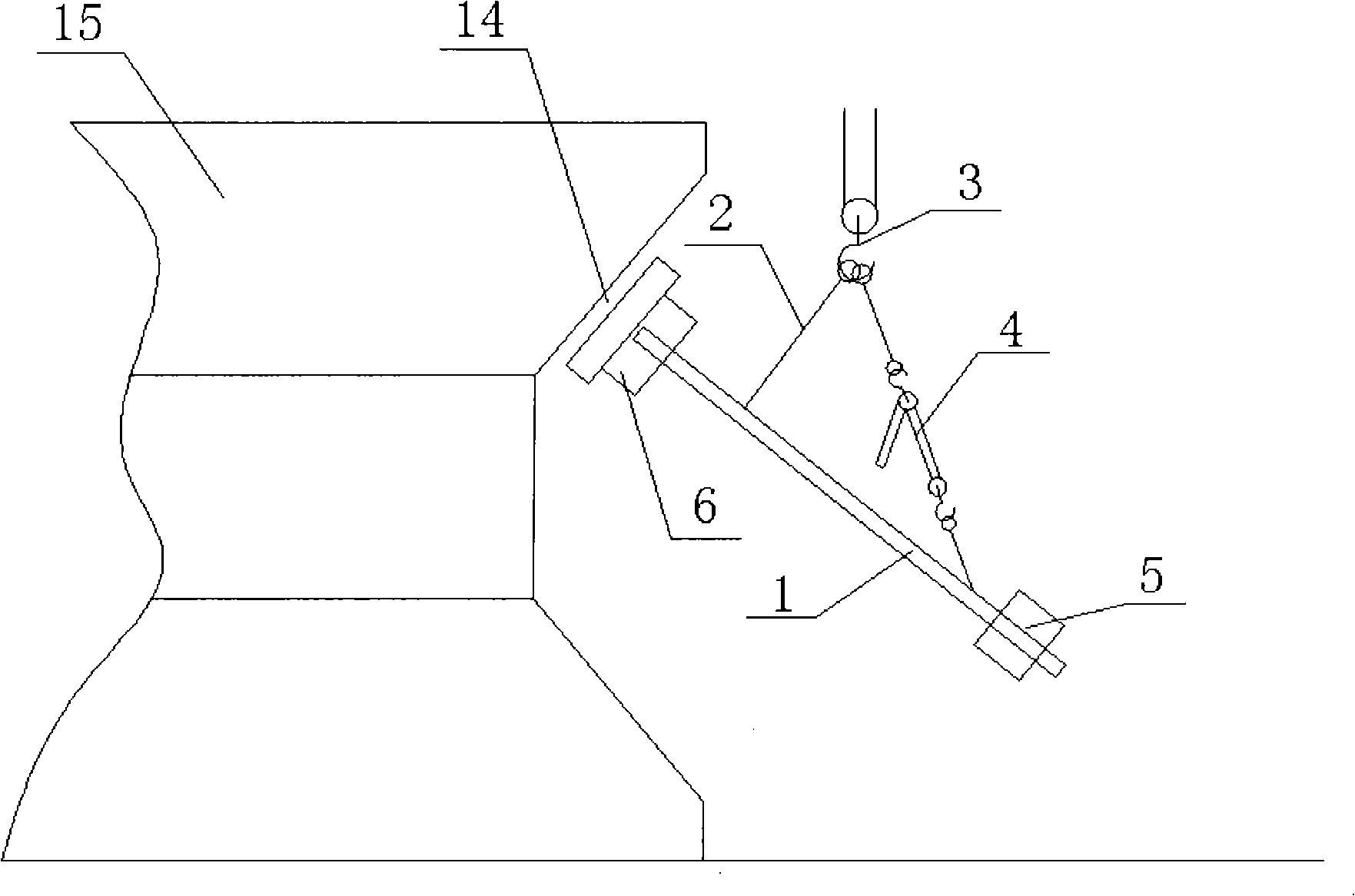

[0031] Such as image 3 Shown is a schematic diagram of a method for hoisting counterweights in Embodiment 3. In the manufacturing process of large-scale generators, some objects 6, that is, bakelite parts, are to be installed on the inner chamber slope 14 of the generator 15. Using the present invention, by balancing Rod 1, after the counterweight 5 is added to the other side of the object 6, that is, the bakelite piece, for the inclination requirements of the installation process size of the object 6, that is, the bakelite piece, the object 6, that is, the bakelite piece, can be quickly adjusted by raising and lowering the chain hoist 4 The balance relationship with the counterweight 5 satisfies the technical requirements with high precision. Since the total weight of the object 6, that is, the bakelite part and the counterweight 5, can not exceed the rated lifting capacity of the crane 3, the hoisting is directly carried out with the crane 3, and the front, rear, left, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com