Cast aluminum alloy material for mine-used parts

A technology for casting aluminum alloys and aluminum alloy materials, which is applied in the field of casting aluminum alloy materials to achieve obvious economic and social benefits and wide application prospects

Inactive Publication Date: 2008-10-15

山西省运城安瑞节能风机有限公司

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a casting aluminum alloy material for mining parts, which has a stable and advanced chemical formula, and is safe for friction and sparks, in view of the disadvantage that the parts made of the existing aluminum alloy materials for mining are easy to ignite gas and cause explosion accidents. Good performance, low density, good plasticity, corrosion resistance, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

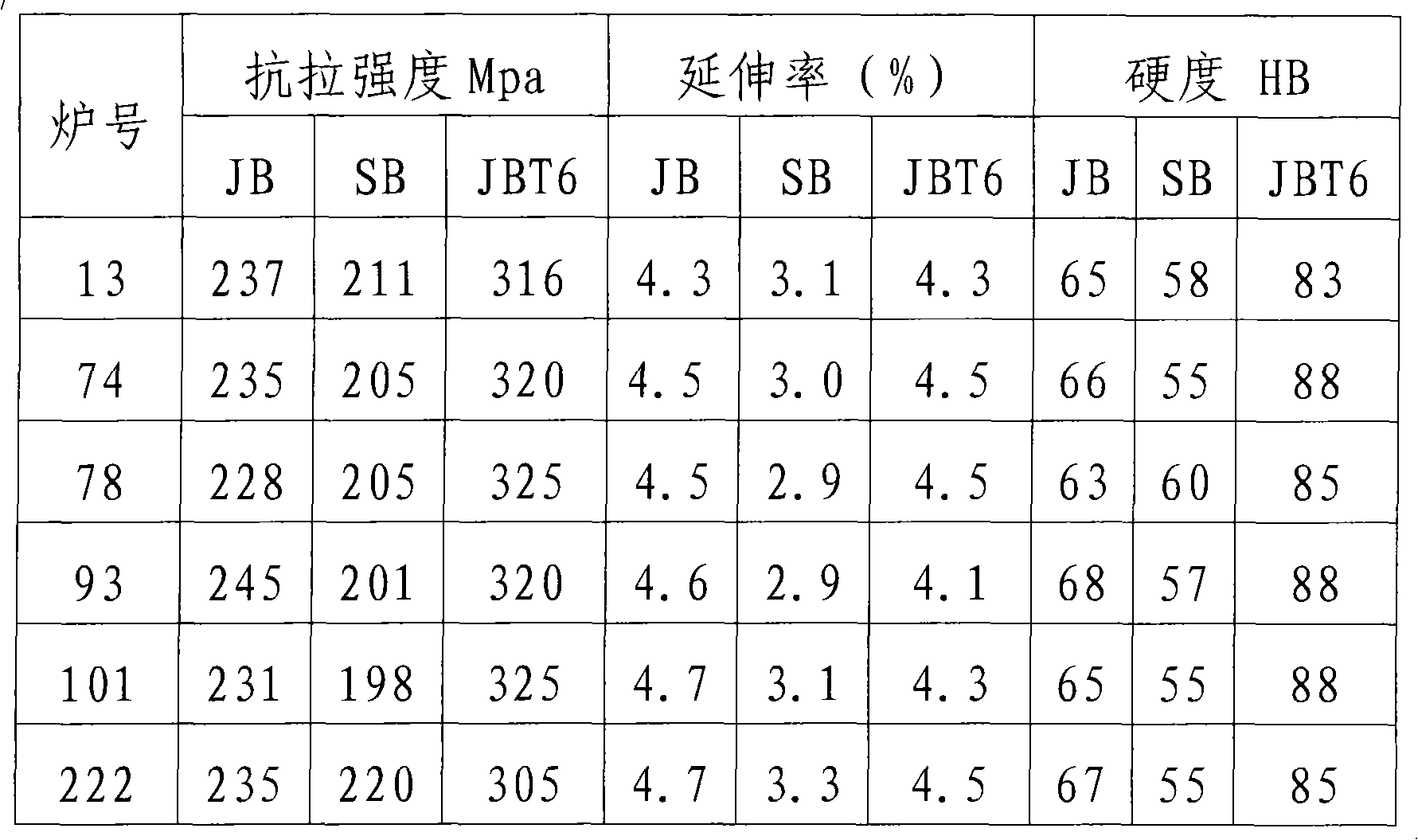

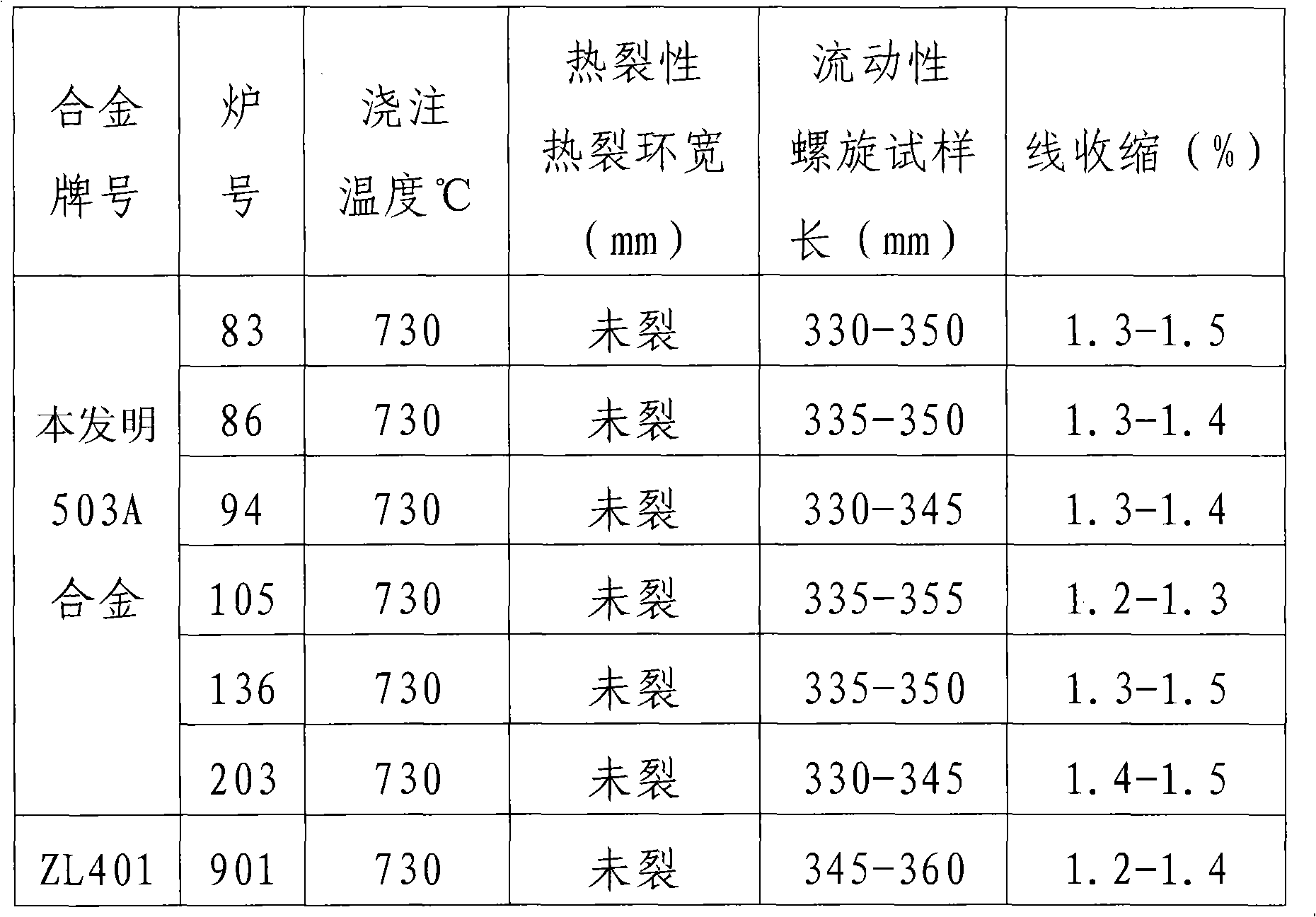

The invention discloses a casting aluminum alloy material for a mine-used part, which relates to a casting aluminum alloy material. An aluminum alloy part used in underground coal mines can generate spark due to collision or friction to fire gas and result in explosion accidents. At present, aluminum equipment is forbidden under the coal mines or within 300 meters of an extraction face with hazardous biogases by many countries. The components in percentage by weight of the invention are: 1.0 to 2.5 percent of Zn,3.0 to 5.5 percent of Cu,0.1 to 0.3 percent of Cr,0.1 to 0.2 percent of Ti,0.02 to 0.05 percent of Be,0.01 to 0.03percent of Sr,0.3 to 0.8percent of Mn, 2.5 to 4.5 percent of Rx,less than or equal to 1.5 percent of Si, less than or equal to 0.5 percent of Mg,less than or equal to 0.5 percent of Fe, the balance being Al. The casting aluminum alloy material has the advantages of good safety of frictional spark, low density, good plasticity and corrosion resistance, etc.

Description

Cast aluminum alloy material for mining parts Technical field The invention relates to a cast aluminum alloy material, in particular to a friction-free spark-free safe cast aluminum alloy material for parts such as mine fans. Background technique Parts made of aluminum alloy, such as local ventilators, portable electric drills, wind coal drills, and electrical equipment casings in coal mines, have caused many accidents due to sparks caused by impact or friction. Therefore, foreign developed countries have long been studying the safety of light alloy materials used in mines, but no breakthrough has been made so far. At present, many countries have banned the use of equipment made of light alloys in coal mines or within 300m of the mining face with biogas danger. my country has also made strict regulations on the use of light alloy materials in underground mines: the sparks generated by impact or friction of light alloy materials (such as ZL401GB / T1173-1995) are most likely to ig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C21/12

Inventor 郭建民仝小虎苏莫明杜崇恒端木峰青

Owner 山西省运城安瑞节能风机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com