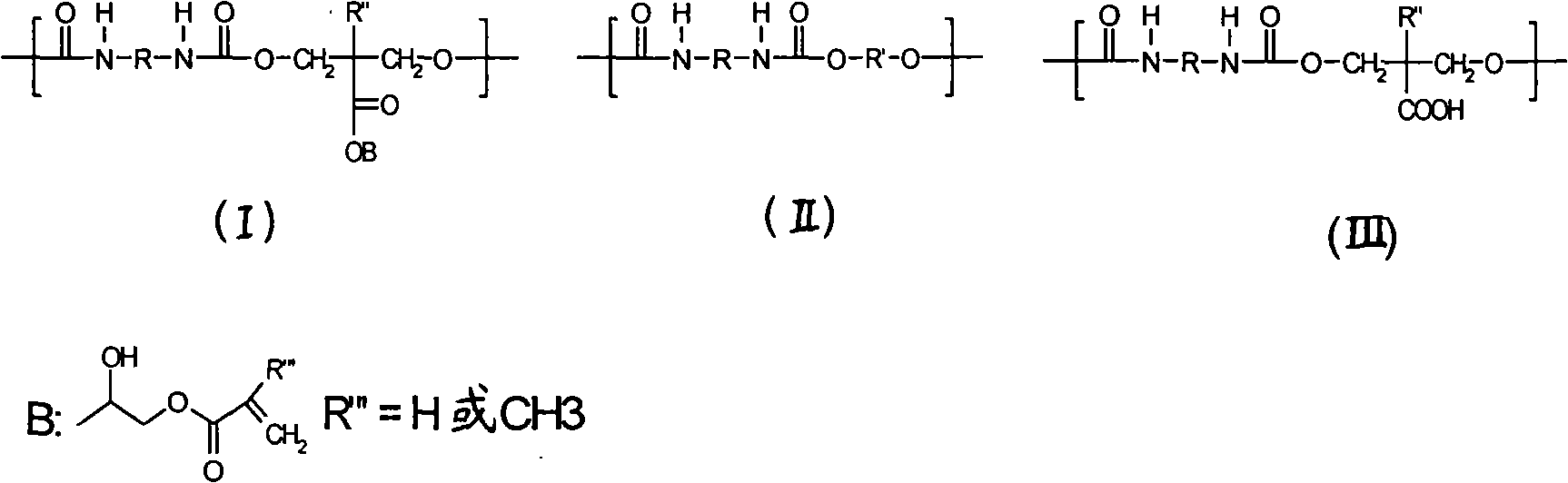

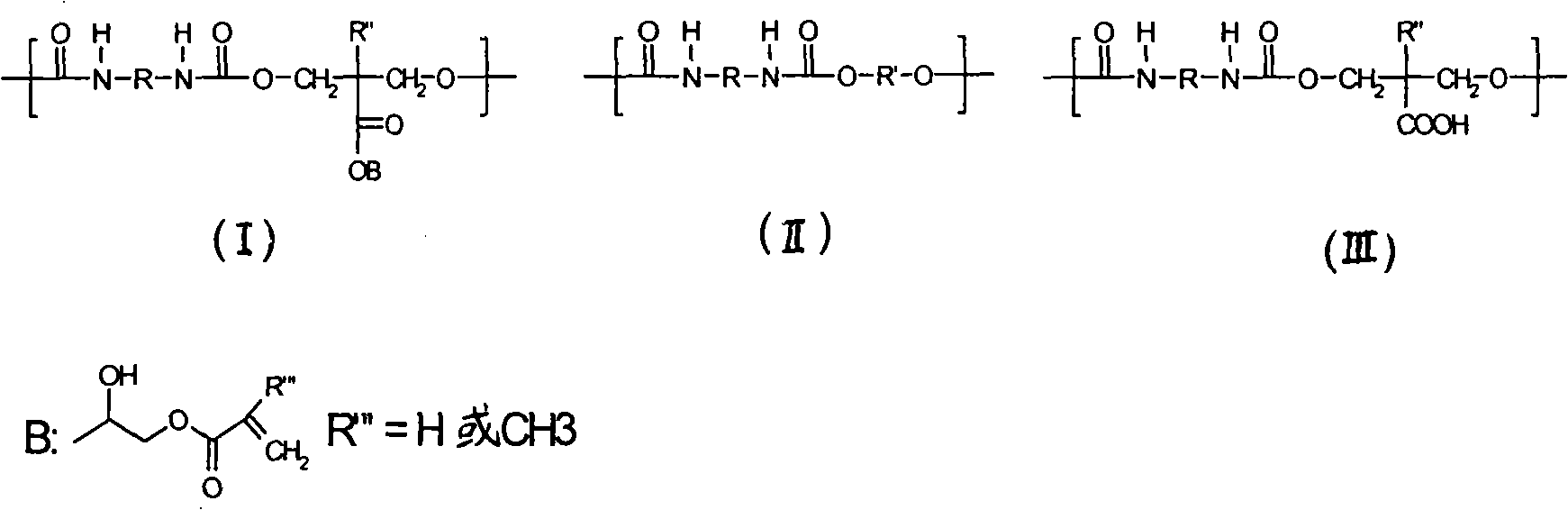

Radiation curable developing polyurethane and radiation curable developing light resistance composition

A radiation curing, polyurethane technology, applied in the field of photoresist composition, can solve the problem of high temperature processing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

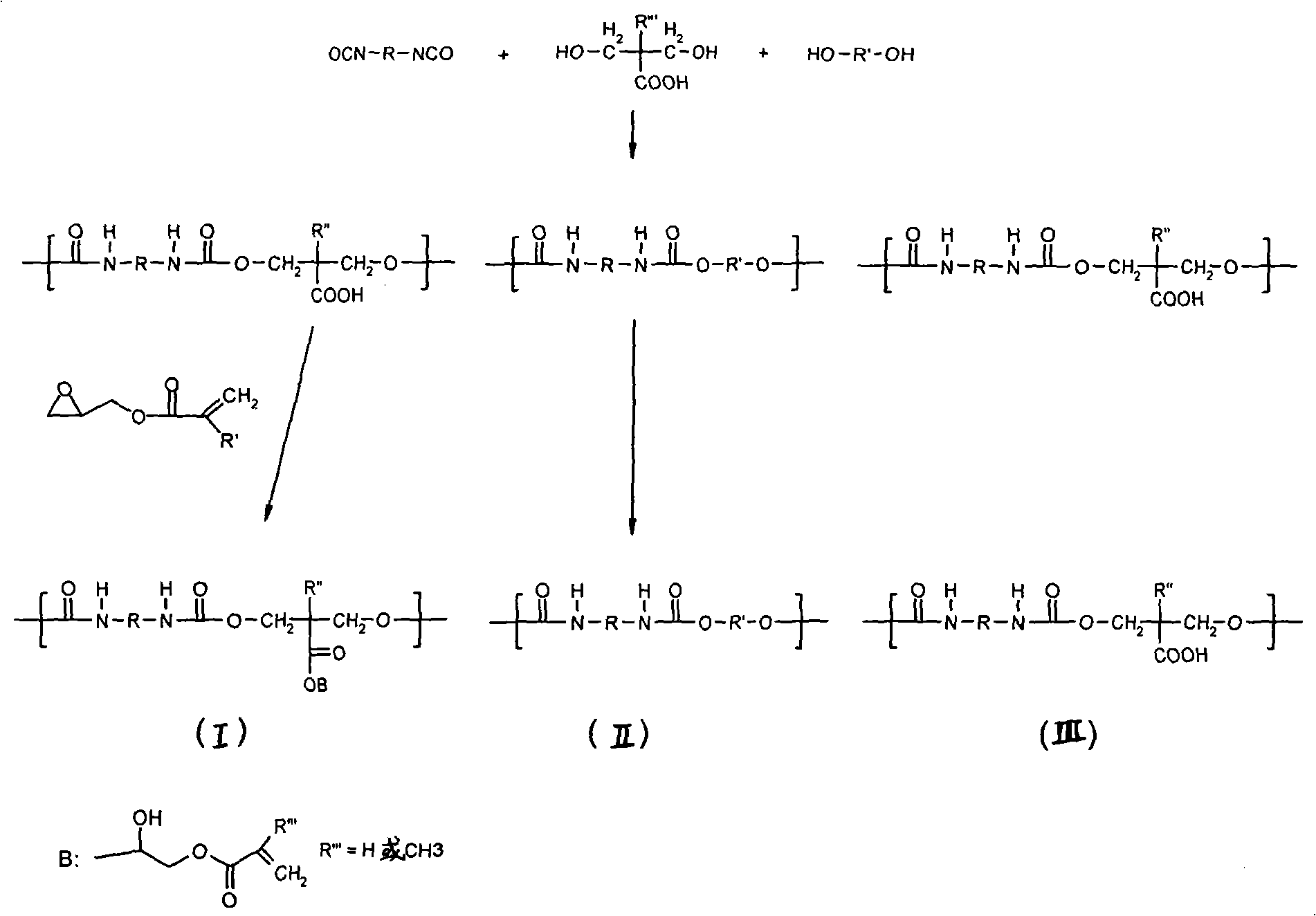

Method used

Image

Examples

Embodiment 1

[0049] Place 31.9 grams of MDI (m-phenylene diisocyanate) and 80 grams of PMA (propylene glycol monomethyl ether acetate) in a 500-mL four-neck separable reaction flask, raise the temperature to 60°C and stir it mechanically Stir with the mixer until the MDI is completely dissolved. Subsequently, 16.2 grams of DMPA (di(hydroxymethyl)propionic acid) and 13.6 grams of PPG-1000 (poly(propylene glycol)-1000) that had been completely mixed in 50 grams of NMP (N-methylpyrrolidone) were added dropwise. Molecular weight is 1000), and after the drop is finished, use FTIR (Fourier Transform Infrared Spectrometer) to judge whether the NCO (isocyanate functional group) has completely reacted. After the reaction is complete, finally raise the temperature to 100° C. and add 8.3 g of GMA (glycidyl methacrylate), and maintain the temperature until the acid value of the solution reaches about 18 mgKOH / g, then the synthesis is completed. The polyurethane 1 with radiation curable development of...

Embodiment 2

[0052] 31.9 g of MDI and 80 g of PMA were placed in a 500 mL four-neck separable reaction flask, the temperature was raised to 60° C. and stirred with a mechanical stirrer until the MDI was completely dissolved. Subsequently, start to drop 16.2 grams of DMPA and 13.6 grams of CAPA that have been completely mixed in 50 grams of NMP beforehand. 2101A (polycaprolactone diol) (molecular weight: 1000), and use FTIR to judge whether the NCO is completely reacted after the drop is completed. After the reaction is complete, finally raise the temperature to 100° C. and add 8.3 g of GMA, and maintain the temperature until the acid value of the solution reaches about 18 mgKOH / g, then the synthesis is completed. The radiation-curable and developable polyurethane 2 of the present invention is obtained, and the Mw measured by GPC (gel permeation chromatography) is 15,000-35,000.

Embodiment 3

[0054] 31.9 g of MDI and 80 g of PMA were placed in a 500 mL four-neck separable reaction flask, the temperature was raised to 60° C. and stirred with a mechanical stirrer until the MDI was completely dissolved. Subsequently, 16.2 g of DMPA and 13.6 g of PC-diol (molecular weight: 1000) which had been completely mixed with 50 g of NMP were added dropwise, and after the drop was completed, FTIR was used to determine whether the NCO had completely reacted. After the reaction is complete, finally raise the temperature to 100° C. and add 8.3 g of GMA, and maintain the temperature until the acid value of the solution reaches about 18 mgKOH / g, then the synthesis is completed. The radiation-curable and developable polyurethane 3 of the present invention is obtained, and the Mw measured by GPC (gel permeation chromatography) is 15,000-35,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap