Method and device for friction compensation

A friction compensation and parameter compensation technology, applied in transportation and packaging, strip winding, thin material handling, etc., can solve the problems of huge cost, increase the probability of system failure, unable to optimize the setting adjustment algorithm, etc., and achieve simplification The effect of the algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

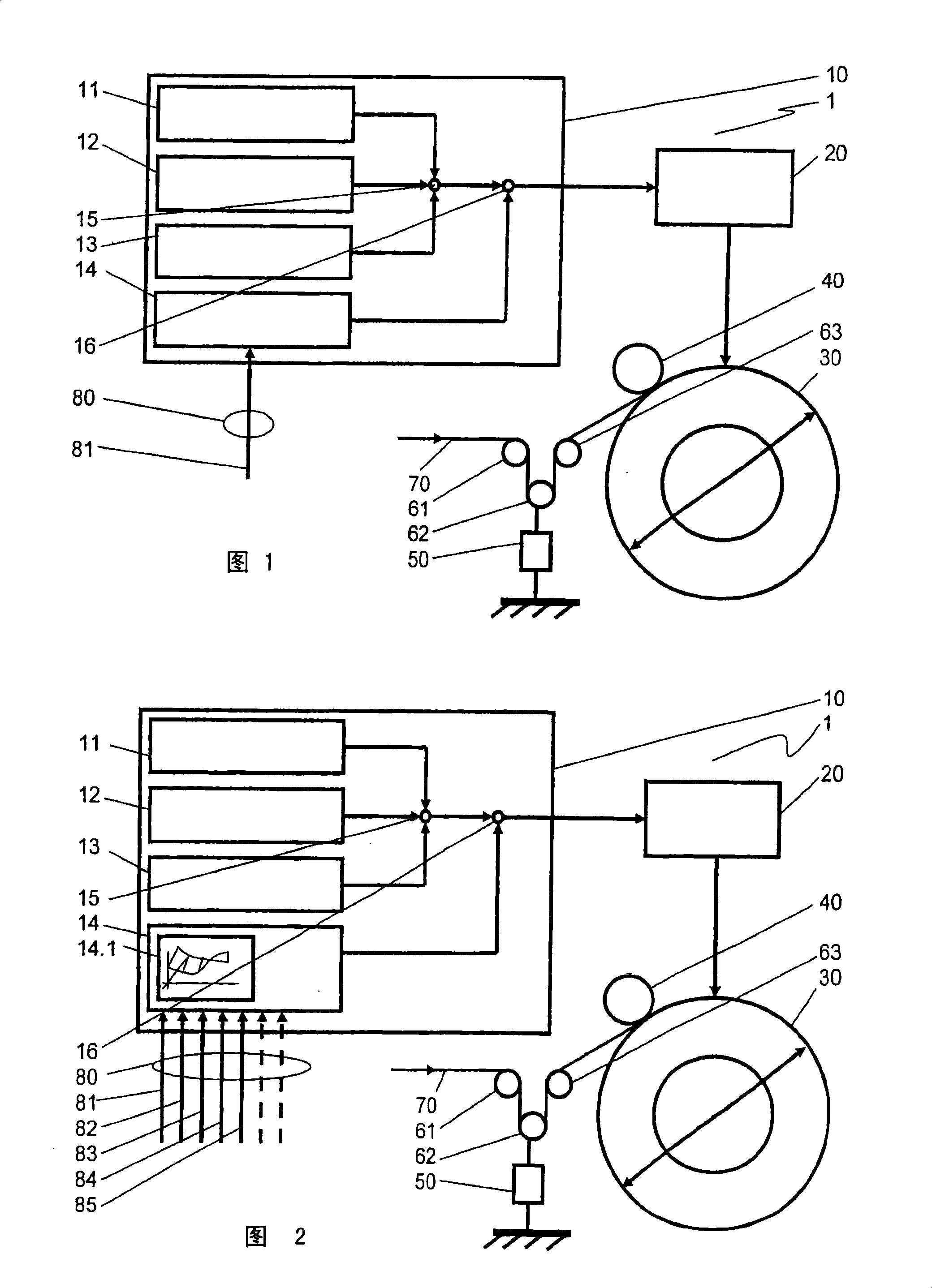

[0036] FIG. 1 shows a winding machine 1 with the essential component winding drum 30 driven by a winding drive 20 . The material 70 to be wound, for example a strip-shaped product, passes first in the illustrated embodiment first through a first deflection device 61, here designed as a fixed roller, and then through a second deflection device 62, here designed as a floating roll The roller is then guided by a third reversing device 63 in the form of another fixed roller, and the material 70 finally leads to the winding drum 30, wherein, in the embodiment shown, the pressure roller 40 compresses the material 70 against the roll. The shaft is wound on the bobbin 30 in order to avoid air entrapment, for example.

[0037] The reversing device 62 is here mechanically connected to the force-measuring device 50 . One side of the force-measuring device 50 is firmly connected to the winder 1 , which force-measuring device can be implemented, for example, as a force cell, by means of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com