Construction method of continuous wall trench underground on soft soil region

A technology for underground diaphragm walls and construction methods, which is applied in sheet pile walls, foundation structure engineering, construction, etc., and can solve the difficulty of crossing through trenches in underground diaphragm walls, the slow speed of trenching in underground diaphragm walls, and the verticality of trenches in underground diaphragm walls Problems such as poor control can be achieved to ensure the formation of grooves, improve the verticality of grooves, and speed up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

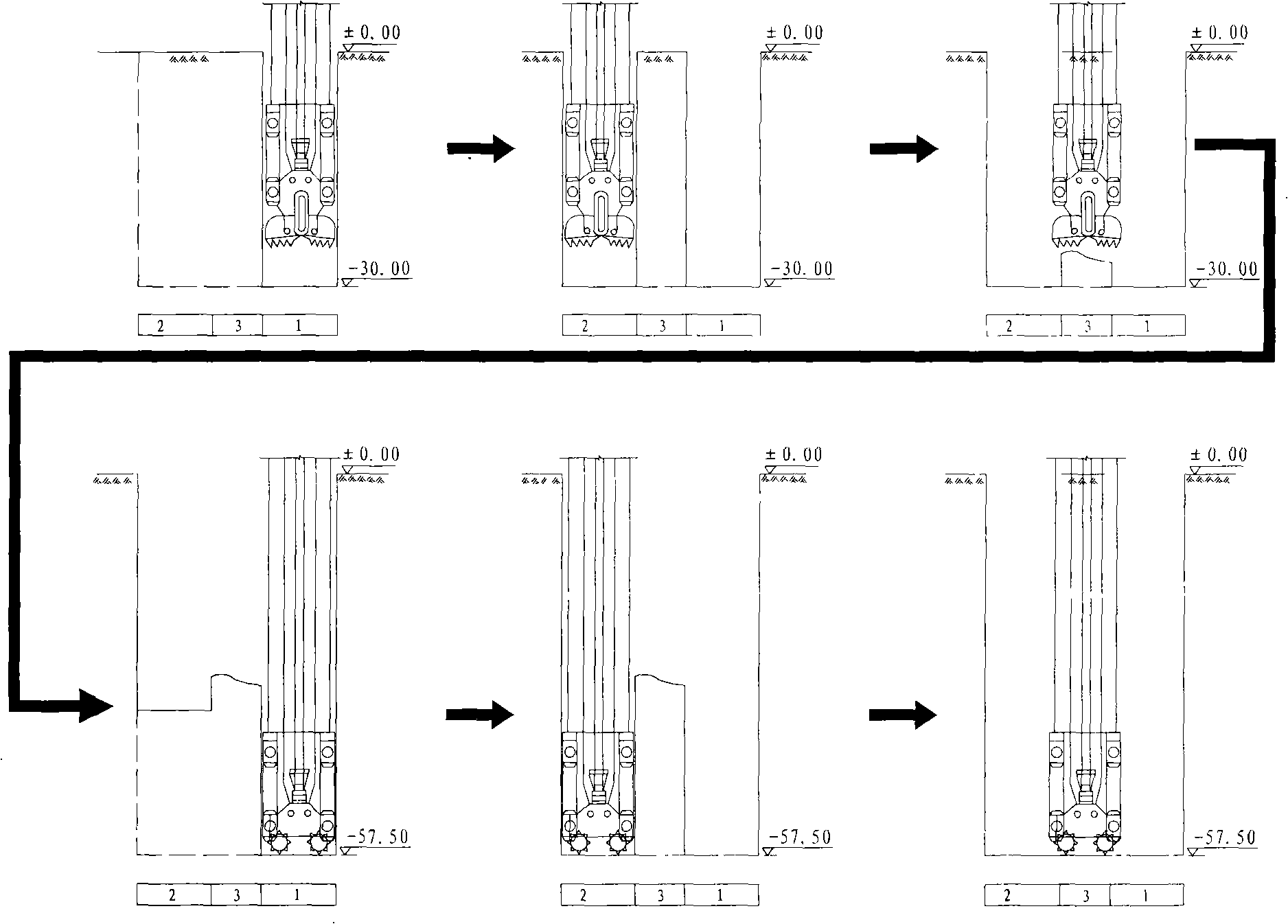

[0045] A construction method for trenching an underground diaphragm wall in a soft soil area, comprising the following steps:

[0046] Step 1, guide wall construction;

[0047] This project adopts an inverted "L" type guide wall, the top elevation of the guide wall is 2.800m, the depth of the guide wall is 1.8m; the distance between the guide walls is 1240mm, the concrete is commercial concrete, and the strength grade is C20;

[0048] Step 1.1, engineering measurement;

[0049] The axis of the guide wall must be reviewed and authenticated by the supervisor before excavation;

[0050] Step 1.2, digging and clearing obstacles;

[0051] Step 1.3, fabrication and installation of guide wall reinforcement;

[0052] After the excavation of the guide wall trench is completed, immediately introduce the center line under the trench to control the construction of the bottom form and formwork to ensure that the center line of the guide wall is correct;

[0053] Step 1.4, guide wall fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap