Optical pressure sensitive coating gauging pressure accuracy enhancing method

A technology of pressure and paint, applied in the field of pressure measurement, can solve the problems of low precision and cumbersome work, and achieve the effect of eliminating reference errors, solving the effect of errors affecting the accuracy of experimental measurement, and eliminating the effect of errors affecting the accuracy of experimental measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

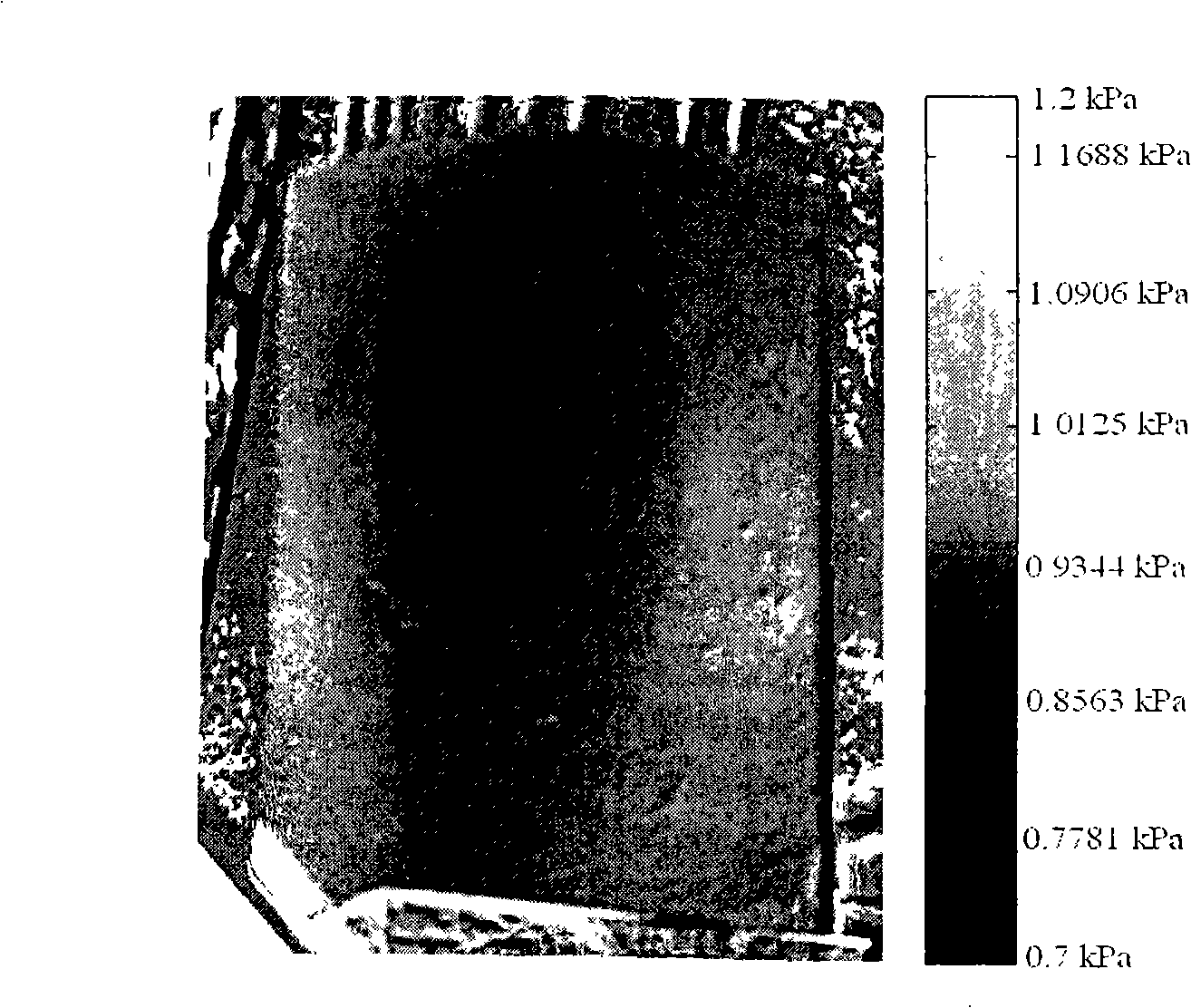

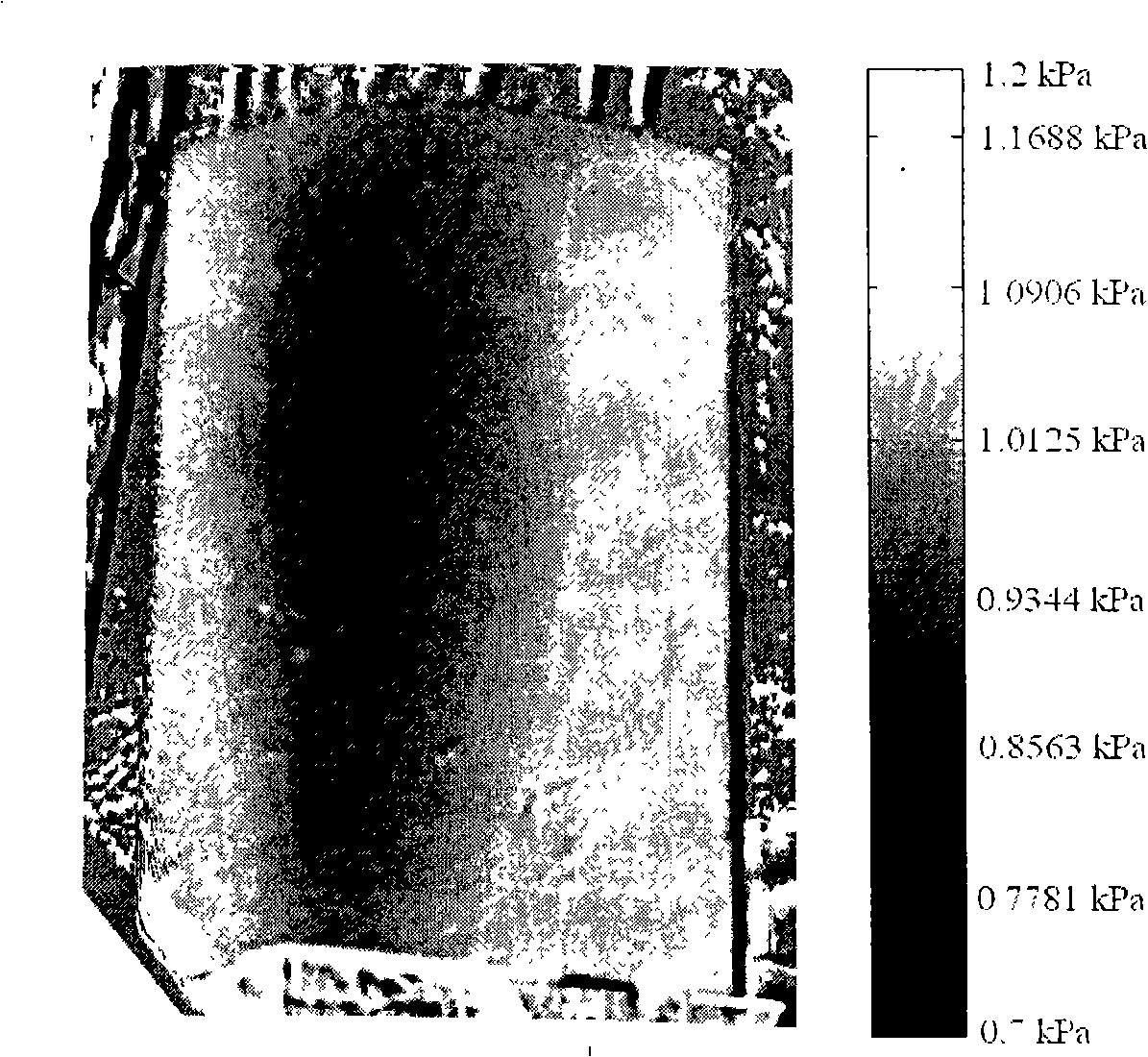

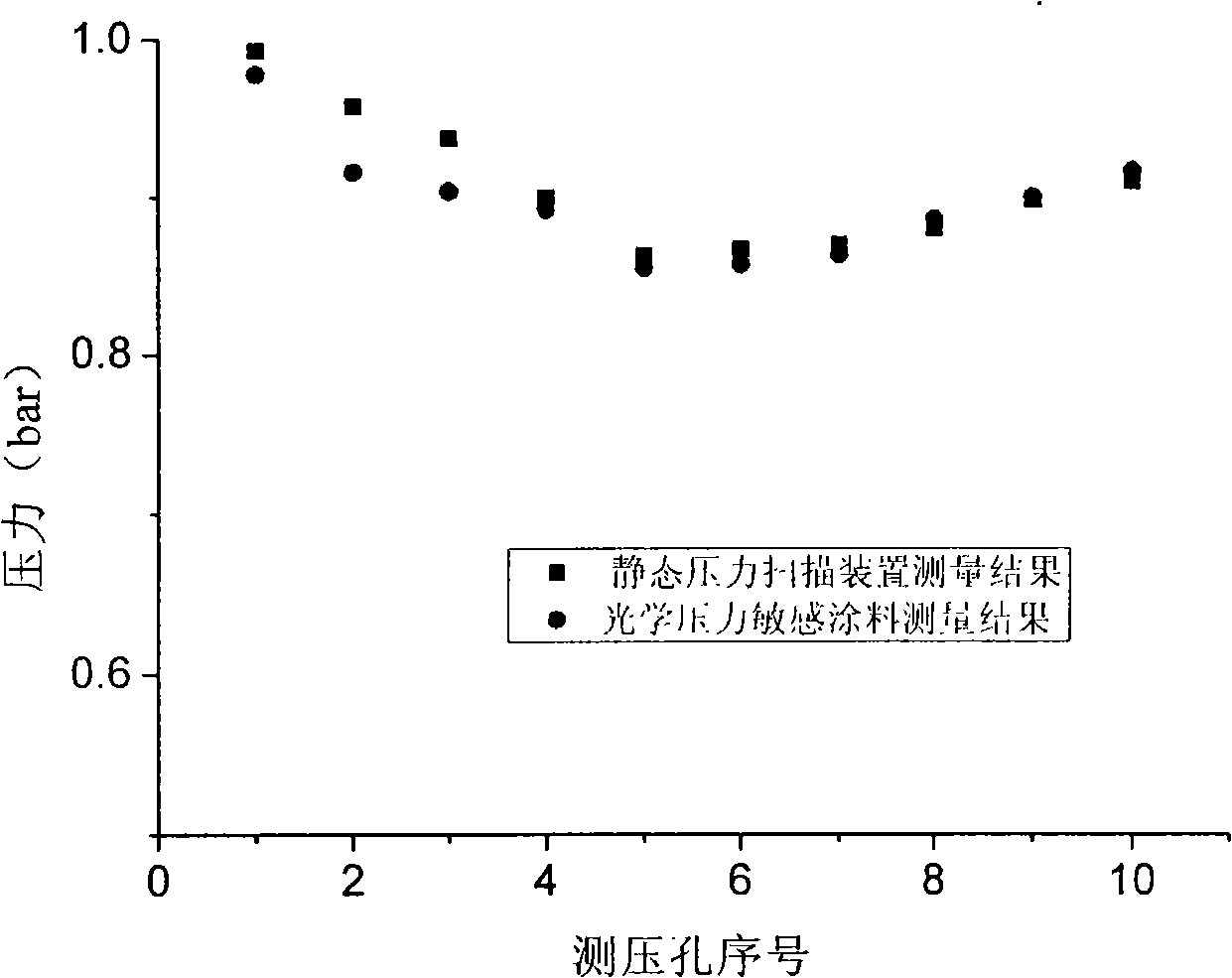

[0030] Example of method implementation: Applying optical pressure-sensitive paint to the pressure measurement of the suction surface of the isolated straight blade at the outlet of the transonic cascade wind tunnel.

[0031] The experimental measurement equipment and facilities consist of a transonic cascade wind tunnel, straight blades coated with domestic optical pressure-sensitive paint, and an optical pressure-sensitive paint measurement system. The suction surface of the rectified straight blade of the compressor is used as the pressure measurement surface, and the domestic fluorescent optical pressure sensitive paint is sprayed as the pressure sensor. Sensitive optical pressure sensitive paint. Fix the selected isolated blade at the outlet of the transonic cascade wind tunnel.

[0032] 1. Pre-design and layout of the experiment. In order to ensure the illumination of the excitation light on the surface of the paint layer and facilitate the digital imaging equipment to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com