A Controlled Machining Technology of Bearing Hole Coefficient in Wedge-shaped Crankcase Cover

A wedge-shaped crankshaft and processing technology, applied in metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of reference misalignment error, inability to directly contact, reduce L1 processing dimensional accuracy, etc., to eliminate reference error, Effects of improving surface accuracy and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is further described:

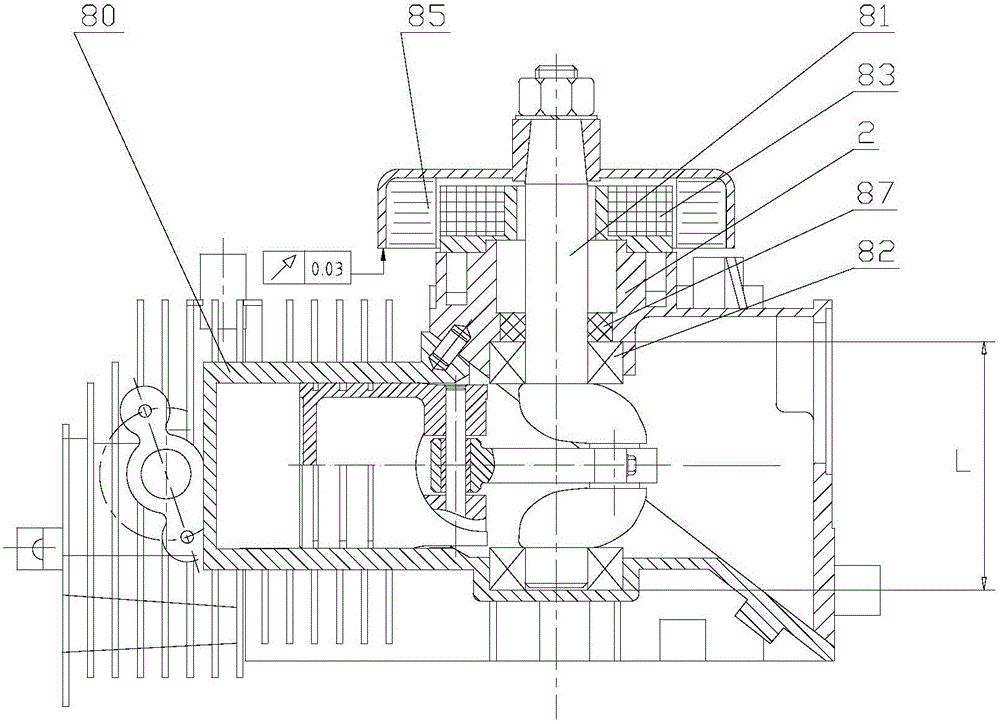

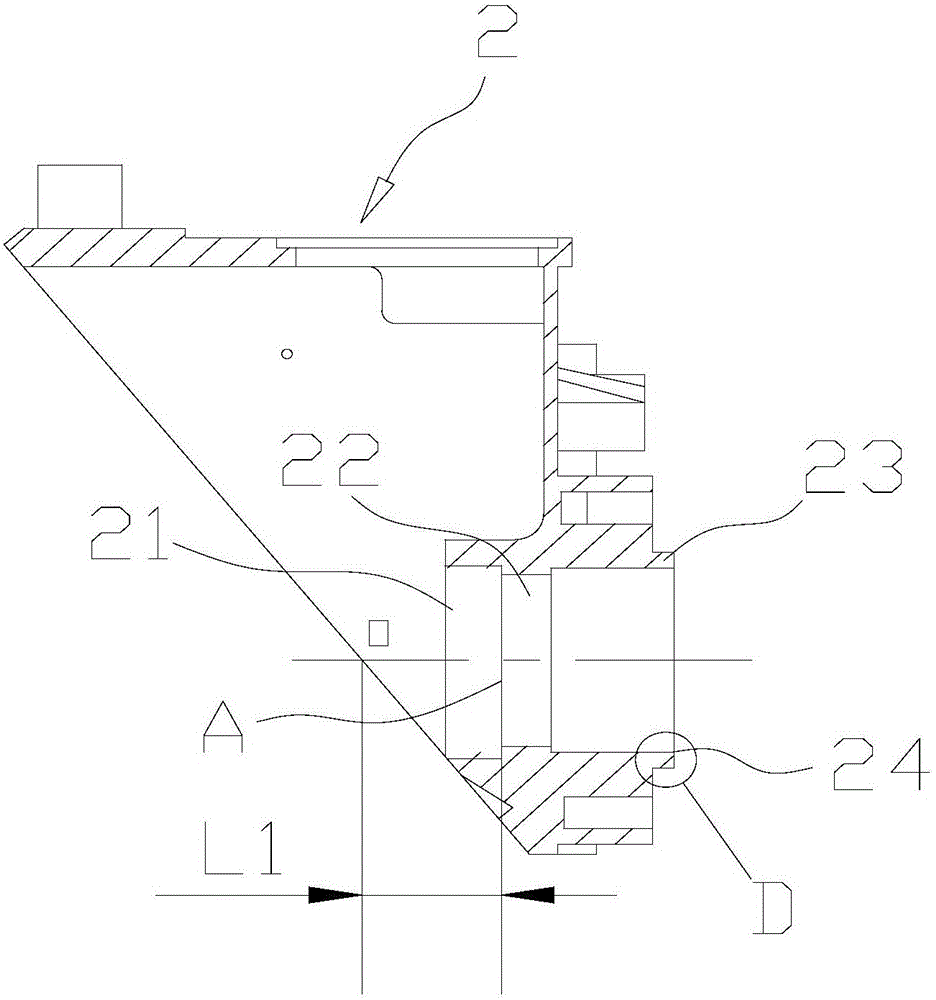

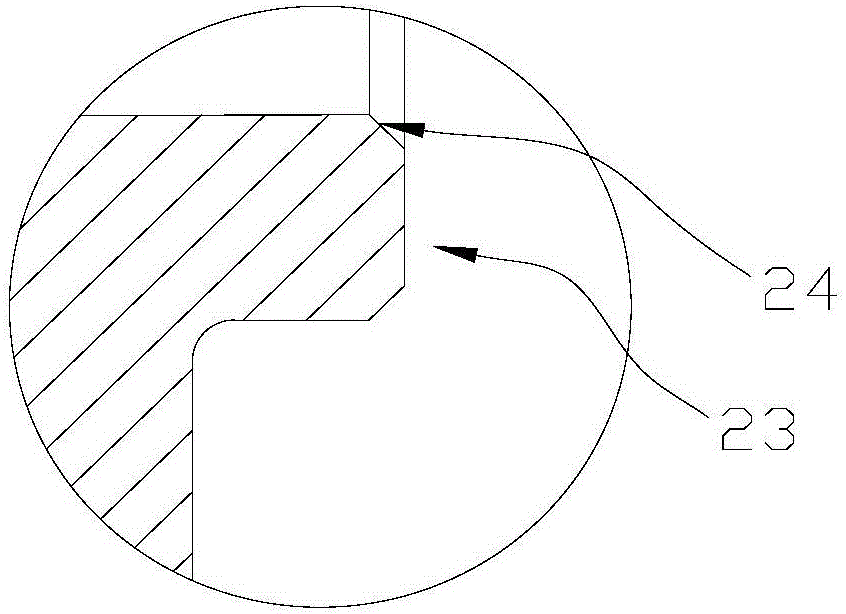

[0033] see Figure 1 to Figure 5 , the present invention is a wedge-shaped crankcase cover bearing hole coefficient control processing technology, including the following steps:

[0034] Step 1. Design and manufacture a positioning fixture, and install the positioning fixture 1 on the spindle of the CNC lathe, so that the central axis of rotation of the positioning fixture 1 coincides with the axis of the main shaft of the lathe; fix the wedge-shaped crankcase cover 2 on the positioning fixture 1, so that the wedge-shaped crankshaft The common axis of the bearing hole system on the box cover 2 coincides with the axis of the lathe spindle, so that the lathe spindle, the rotation center axis of the positioning fixture 1 and the common axis of the bearing hole system of the wedge-shaped crankcase cover 2 can be coaxial; The main body of the positioning fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com