Electrolysis solution and electrolytic capacitor using the same

A technology of electrolyte and electrolyte, which is applied in the direction of electrolytic capacitors, capacitors, circuits, etc., and can solve problems such as open circuits of capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

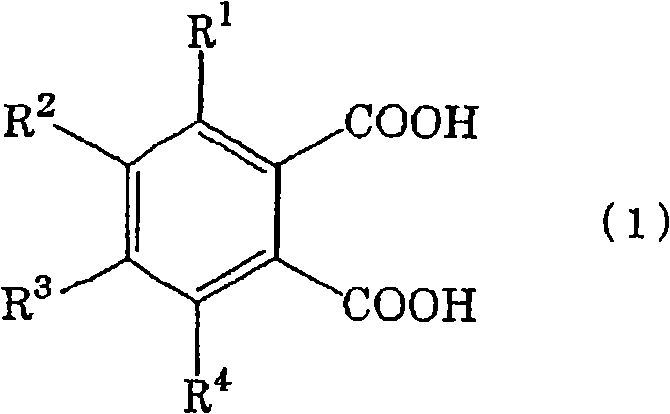

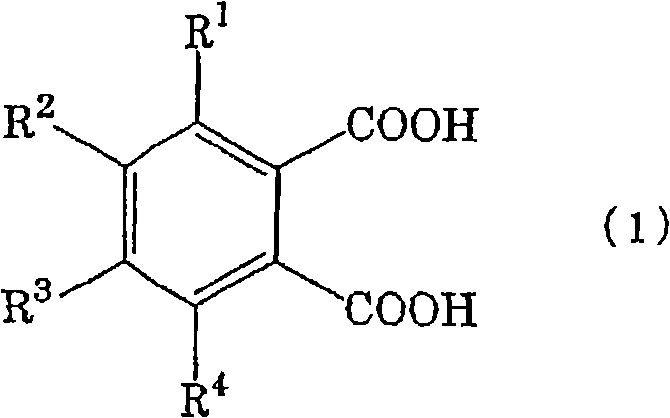

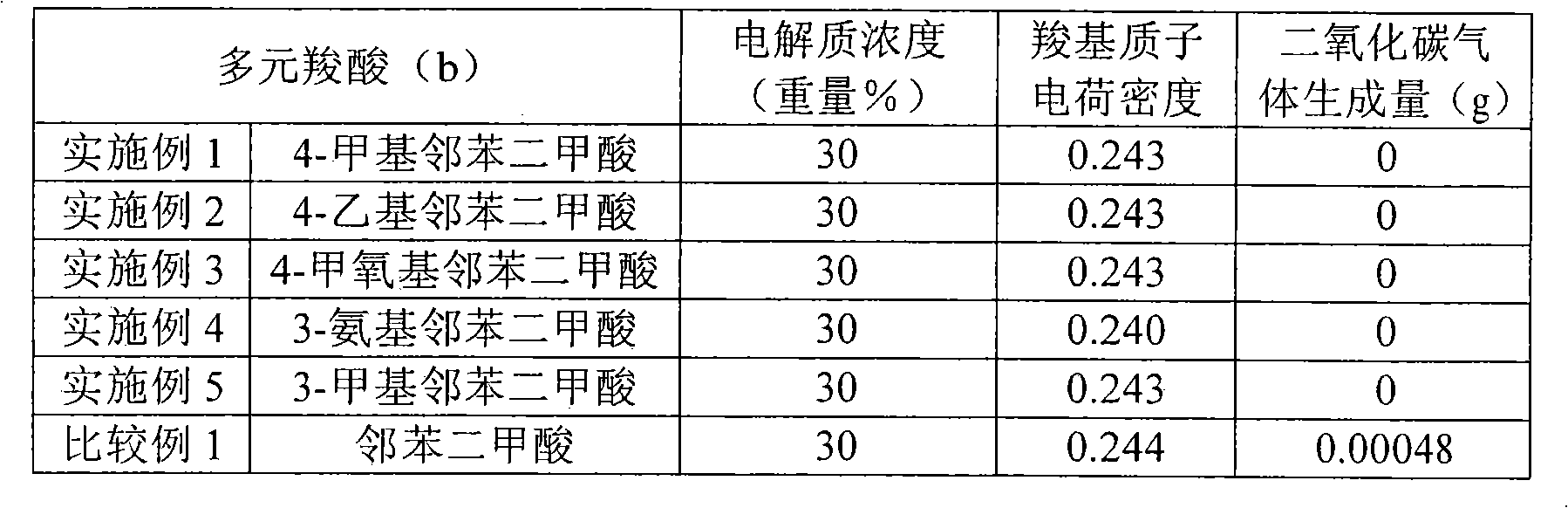

[0078] [Manufacture of 1,2,3,4-tetramethylimidazolinium 4-methylphthalate (A-1)]

[0079] In a 1 L stirred autoclave made of SUS, 270.0 g of dimethyl carbonate and 98-0 g of 1,2,4-trimethylimidazoline were filled and reacted at a reaction temperature of 130° C. for 24 hours. After the reaction, the autoclave was cooled, and the reaction solution was analyzed by liquid chromatography. The conversion rate of 1,2,4-trimethylimidazoline was 95.0%. Unreacted materials and by-product methanol produced during the reaction were distilled off to obtain 180 g of 1,2,3,4-tetramethylimidazolinium methyl carbonate (a-1). Next, 30.0 g of the obtained 1,2,3,4-tetramethylimidazolinium methyl carbonate was dissolved in 200.0 g of methanol, and 78.6 g of 4-methylphthalic acid was slowly added, and the reaction was violent, resulting in carbon dioxide gas. Deaeration was performed at 80° C. / 20 mmHg to remove methanol to obtain 48.0 g of 1,2,3,4-tetramethylimidazolinium·4-methylphthalate (A-1)....

manufacture example 2

[0081] [Manufacture of 1,2,3,4-tetramethylimidazolinium 4-ethylphthalate (A-2)]

[0082] Except that 84.7 g of 4-ethylphthalic acid was used instead of 78.6 g of 4-methylphthalic acid, the same procedure as in Production Example 1 was carried out to obtain 1,2,3,4-tetramethylimidazolinium 4- 50.2 g of ethyl phthalate (A-2).

manufacture example 3

[0084] [Manufacture of 1,2,3,4-tetramethylimidazolinium 4-methoxyphthalate (A-3)]

[0085] Except that 85.6 g of 4-methoxyphthalic acid was used instead of 78.6 g of 4-methylphthalic acid, 1,2,3,4-tetramethylimidazolinium 4 was obtained in the same manner as in Production Example 1. - 50.5 g of methoxyphthalate (A-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com