A method for preparing dimer acid by temperature-programmed oleic acid dimerization

A temperature-programmed, dimer acid technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of darkening of product color, long reaction time, environmental pollution, etc., and achieve post-processing burden Reduce the amount of catalyst, reduce the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

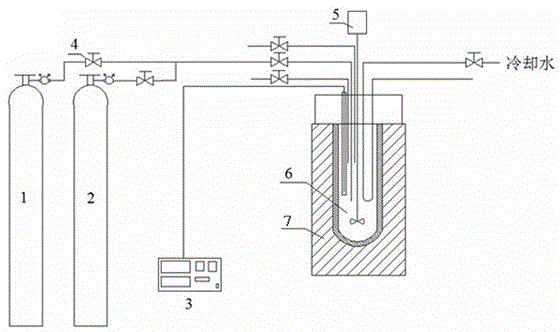

Image

Examples

Embodiment 1

[0021] A method for preparing dimer acid by temperature-programmed oleic acid dimerization, comprising the steps of:

[0022] 1) Add the raw material cottonseed oleic acid, activated clay with 5% weight of raw material and lithium carbonate with 0.1% weight of raw material into a clean reactor;

[0023] 2) After locking the reactor, nitrogen gas was introduced several times to exhaust the air in the reactor, and then the decarboxylation inhibitory gas CO with a pressure range of 0.5MPa was introduced. 2 , stirring and heating;

[0024] 3) Set the first-stage reaction temperature to 180°C and turn on the heating equipment. After the temperature reaches the set temperature, react for 2 hours. After the reaction is completed, adjust the heating power to raise the reaction temperature to the second-stage reaction temperature of 280°C. Continue to react for 0.5 hour;

[0025] 4) After the reaction, the obtained reaction product is centrifuged and filtered to remove the catalyst t...

Embodiment 2

[0028] A method for preparing dimer acid by temperature-programmed oleic acid dimerization, comprising the steps of:

[0029] 1) Add the raw material cottonseed oleic acid, molecular sieve catalyst with 6% weight of raw material and lithium carbonate with 0.3% weight of raw material into a clean reactor;

[0030] 2) After locking the reactor, nitrogen gas was introduced several times to exhaust the air in the reactor, and then the decarboxylation inhibitory gas CO with a pressure range of 1.0MPa was introduced. 2 , stirring and heating;

[0031] 3) Set the first-stage reaction temperature to 200°C and turn on the heating equipment. After the temperature reaches the set temperature, react for 1.5 hours. After the reaction is completed, adjust the heating power to raise the reaction temperature to the second-stage reaction temperature of 270°C. Continue to react for 1.5 hours;

[0032] 4) After the reaction, the obtained reaction product is centrifuged and filtered to remove t...

Embodiment 3

[0035] A method for preparing dimer acid by temperature-programmed oleic acid dimerization, comprising the steps of:

[0036] 1) Add the raw material cottonseed oleic acid, activated clay with 7% weight of raw material and lithium acetate with 0.4% weight of raw material into a clean reactor;

[0037] 2) After locking the reactor, nitrogen gas was introduced several times to exhaust the air in the reactor, and then the decarboxylation inhibitory gas CO with a pressure range of 1.5MPa was introduced. 2 , stirring and heating;

[0038] 3) Set the first-stage reaction temperature to 220°C and turn on the heating equipment. After the temperature reaches the set temperature, react for 1 hour. After the reaction is completed, adjust the heating power to raise the reaction temperature to the second-stage reaction temperature of 260°C. Continue to react for 0.5 hour;

[0039] 4) After the reaction, the obtained reaction product is centrifuged and filtered to remove the catalyst to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com