System equipment for production of rhus verniciflua fruit wax

A kind of system equipment and technology of fruit wax, which is applied in the direction of producing fat and the recovery/refining of fatty substances, etc., to achieve the effect of not being easy to carbonize, ensuring the separation effect, and avoiding condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

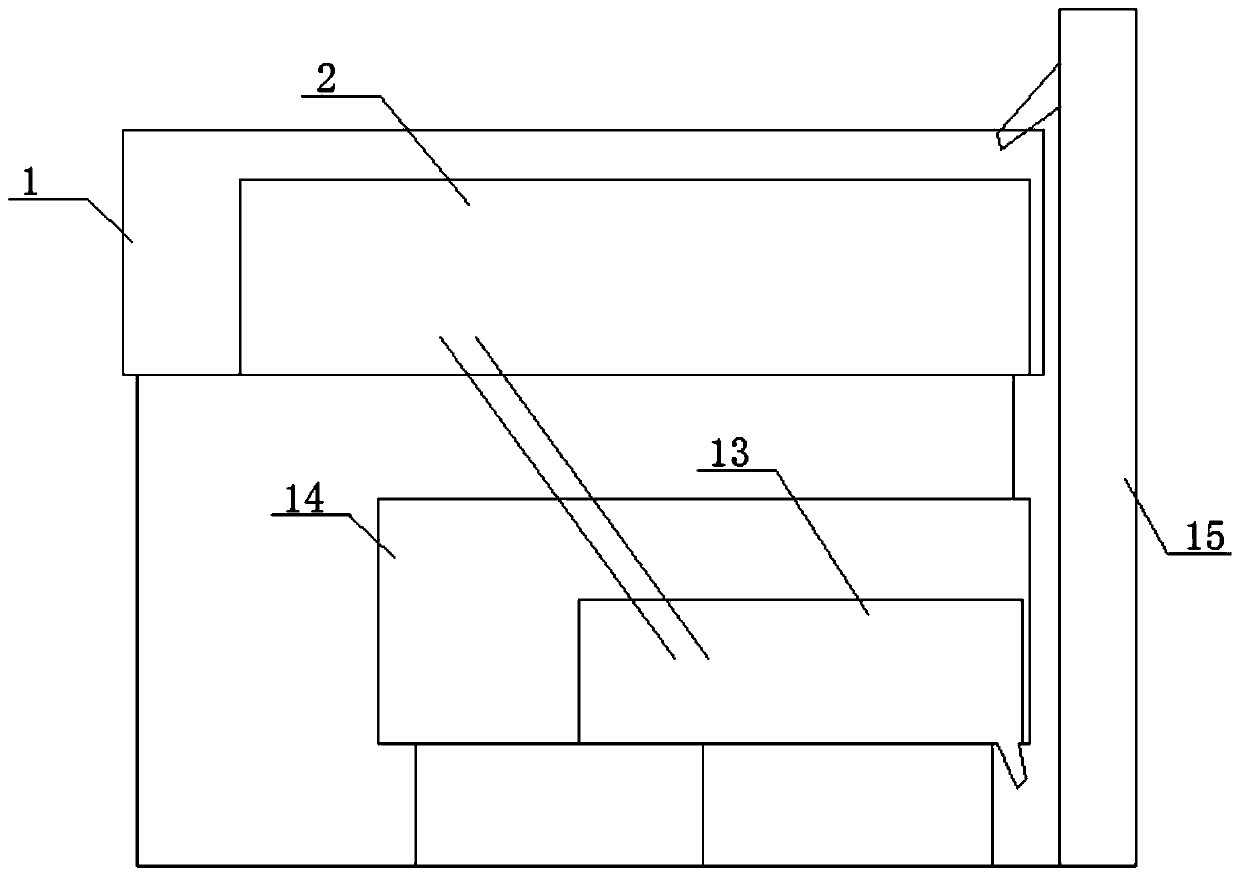

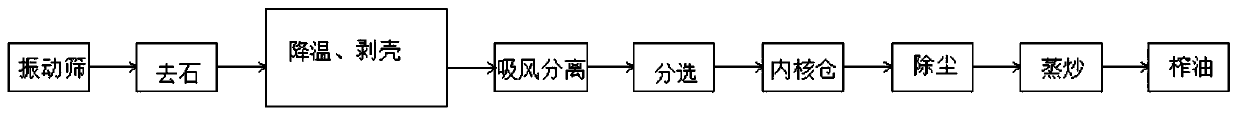

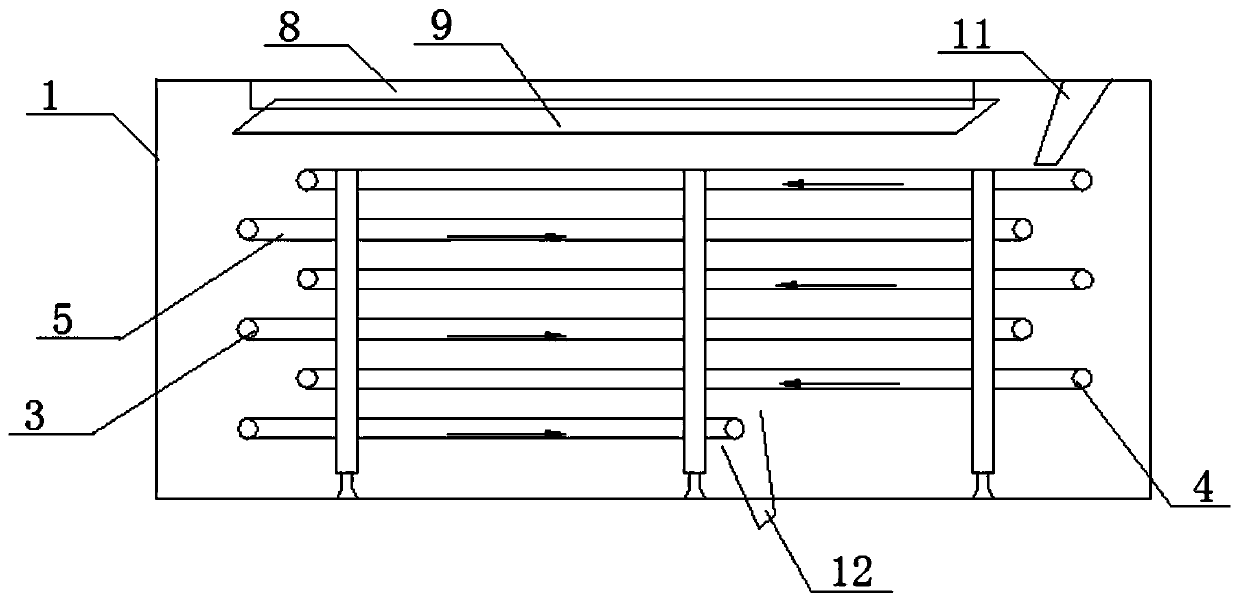

[0030] The system equipment for producing lacquer wax in the present invention includes a vibrating screening machine, a stone removing machine, a cooling device 1, a peeling machine 13, a suction separator, a steaming and frying machine, a screw press, a storage tank 16 and a finished product arranged in sequence. conveying device;

[0031] The outlet of the vibrating screening machine is connected with the inlet of the de-stoner machine through a pipeline, the outlet of the de-stoner machine is connected with the inlet of the cooling equipment, and the outlet of the cooling equipment 1 is arranged above the inlet of the sheller 13, see figure 1 , the outlet of the peeling machine 13 is connected with the inlet of the suction separator, the steaming and frying machine is arranged at the rear end of the suction separator, the outlet of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com