Overhang spindle bumper absorber for airliner undercart

A technology for large passenger aircraft and landing gear, which is applied to gas-liquid shock absorbers, chassis, etc., can solve the problems of passengers feeling uncomfortable, affecting the strength of landing gear, and discontinuous reaction force, and achieves simplified setting of inflatable holes, convenient and easy inflation. Operation, the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

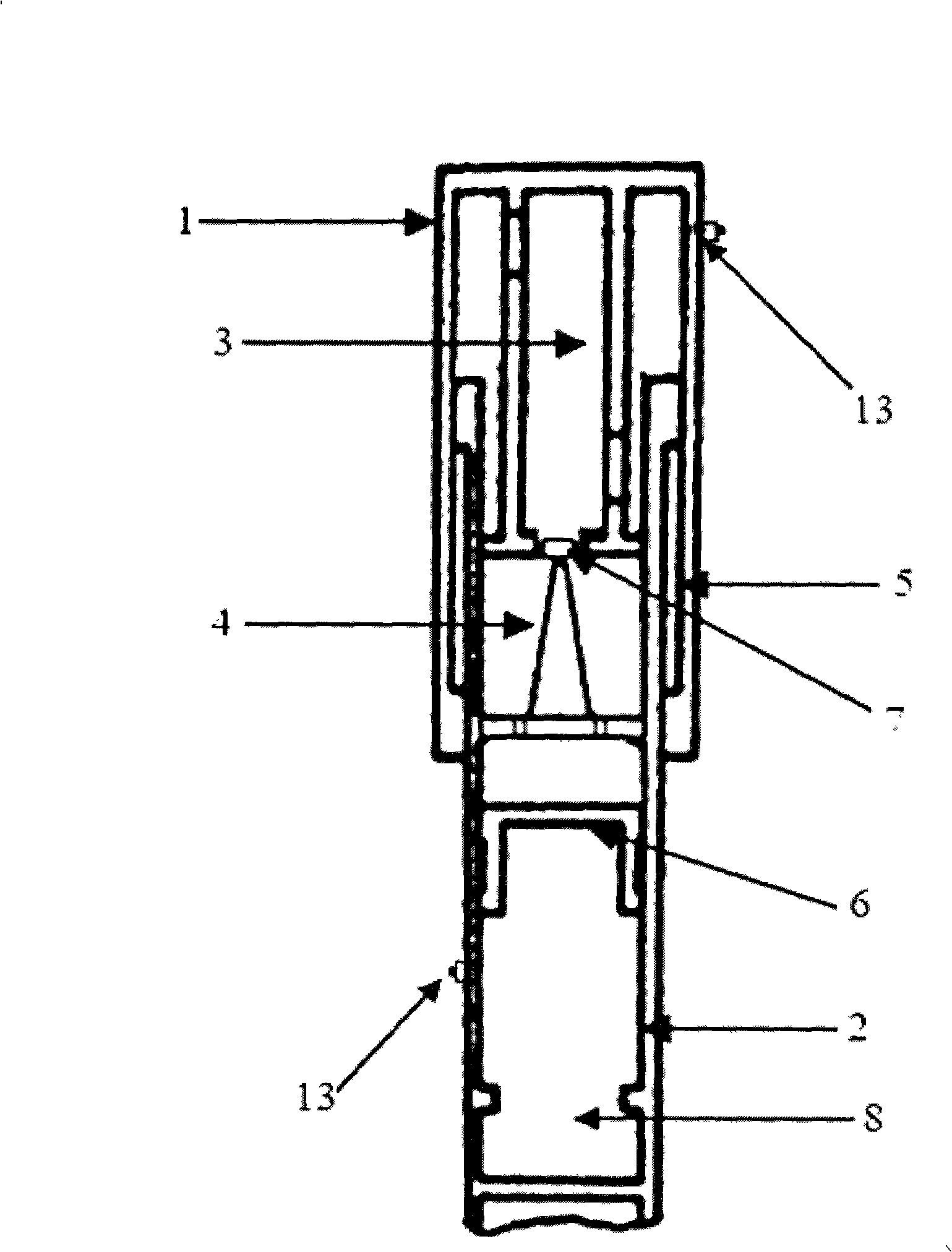

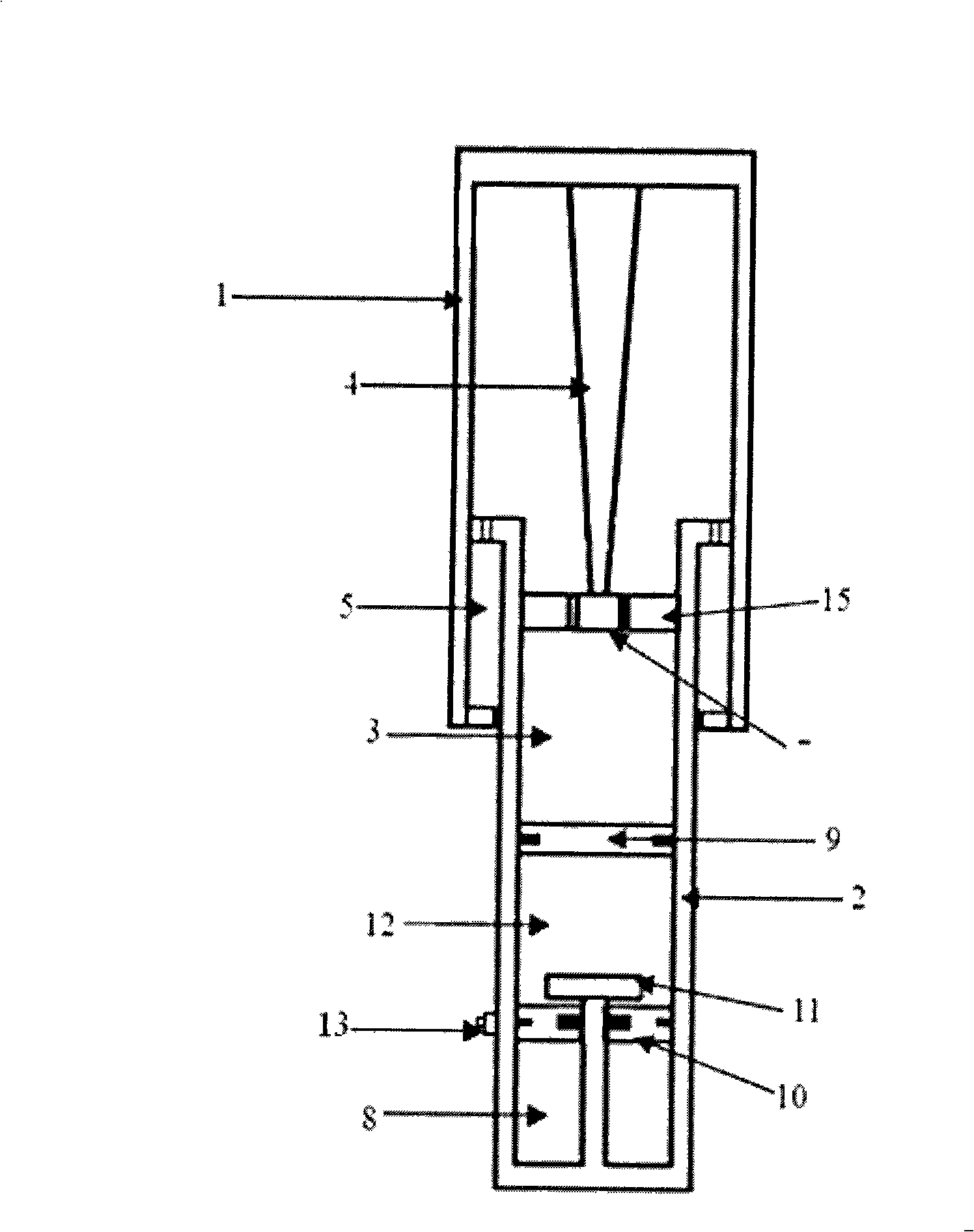

[0018] The present invention resets the placement positions of the traditional buffer air chamber and the oil needle. Such as figure 2 As shown, when the buffer is subjected to external pressure, the low-pressure air chamber 12 is first compressed, and the pressure of the low-pressure air chamber 12 increases thereupon. When the pressure increases to the same pressure as the high-pressure air chamber 8, the high-pressure air chamber 8 starts When the two air chambers are compressed, the oil and gas are pressed into the damping hole 7. Since the oil needle 4 adopts a variable diameter design, the oil needle 4 can change the area of the damping hole 7 at all times when the buffer is compressed.

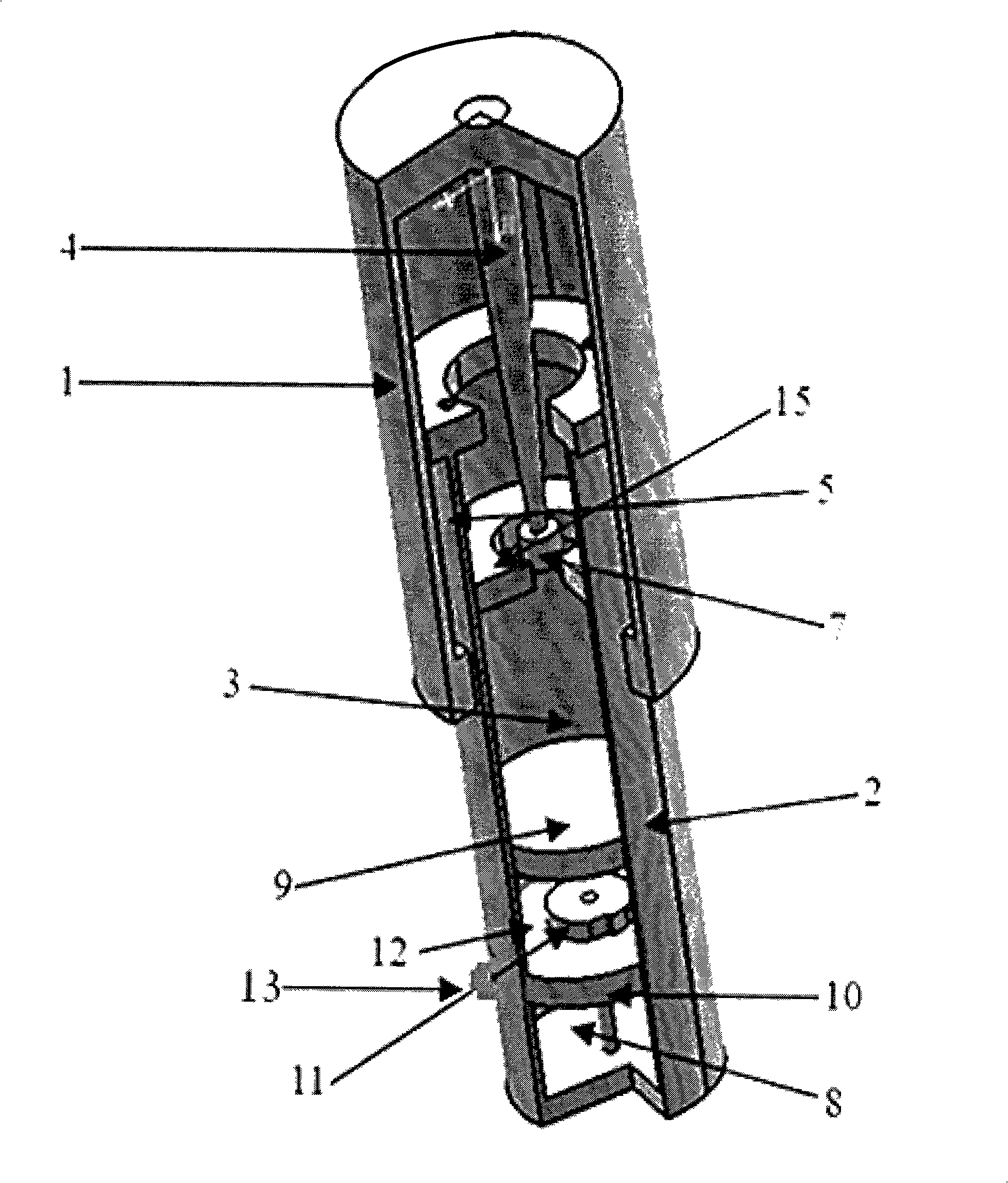

[0019] The main structure of the buffer of the present invention is as image 3 As shown, the high-pressure and low-pressure two air chambers 8, 12 are arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com