Process for preparing glutamic acid crystallization

A glutamic acid and crystallization technology, applied in the field of glutamic acid crystallization, can solve the problems of packaging, transportation difficulties, inability to operate continuously, uneven particles, etc., to solve the problem of sewage discharge, the finished product has good color and sense, and create economy. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Production of glutamic acid crystals from glutamic acid fermentation broth

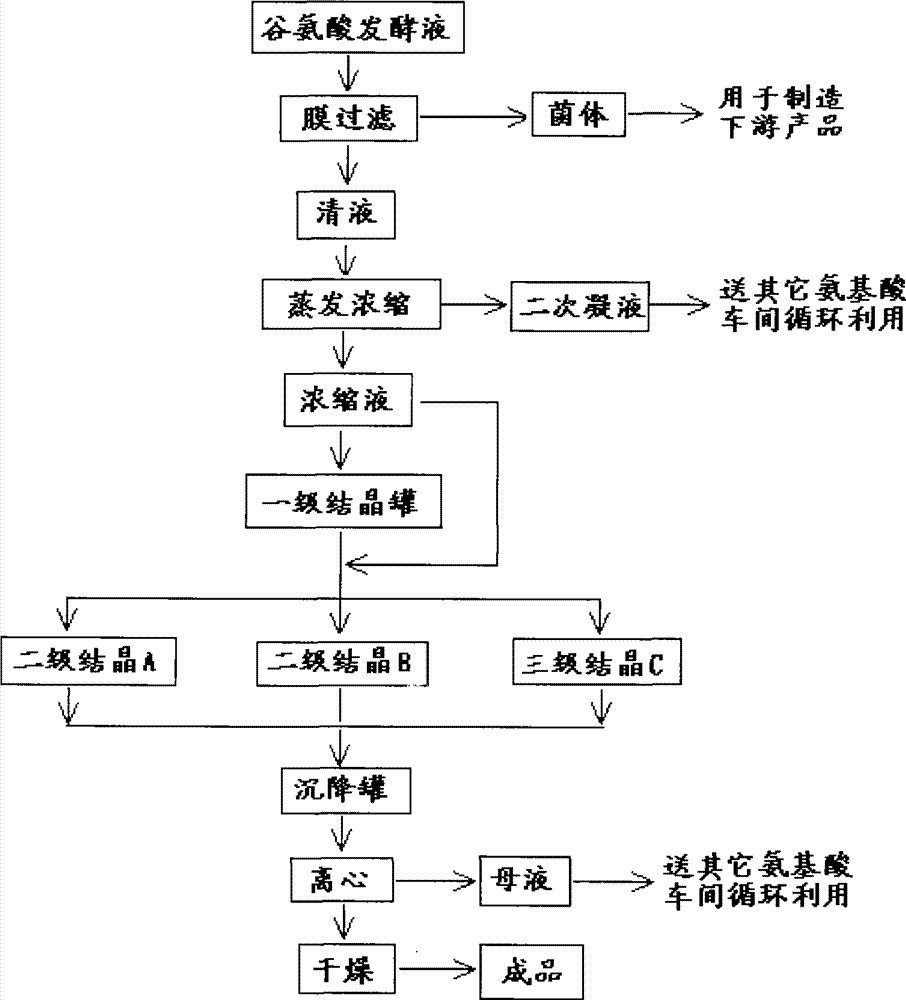

[0043] The production of glutamic acid in this embodiment is according to the attached figure 1 The process flow shown is carried out.

[0044] 1. Operation process

[0045] (1) Glutamic acid fermentation broth 500m 3 , wherein the glutamic acid content is 14g / 100ml, and the pH value is 7.48. With sulfuric acid (concentration 98%) its pH value is adjusted to 5.80, through inorganic ceramic membrane filtration, used ceramic membrane is the K99BW type product that French Orelis produces, and filter condition is: fermentation liquid temperature 70 ℃, membrane inlet pressure is 3~ 3.5kg, outlet pressure 7.0kg. After filtration, the clarified fermentation broth and bacteria were obtained, of which the clear liquid was 487m 3 . The obtained wet cells are sent to the by-product workshop for drying, and after drying, they become cell proteins.

[0046] (2) Concentrate the clarified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com