Preparation of modified polyacrylic acid graft copolymer high-efficiency water-reducing agent

A graft copolymer and high-efficiency water-reducing agent technology is applied in the specific synthesis field of modified polyacrylic acid graft-copolymer high-efficiency water-reducing agents, can solve problems such as poor dispersion retention performance, and achieves improved dispersion retention performance, Good adaptability and cost reduction effect

Inactive Publication Date: 2010-12-01

JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

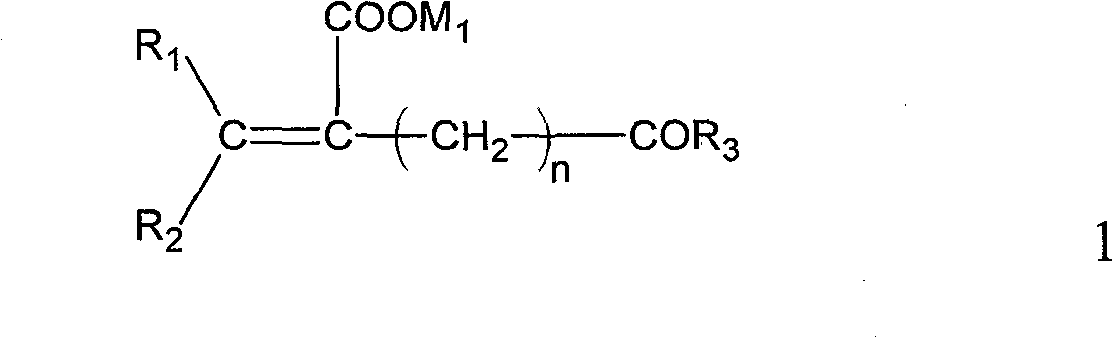

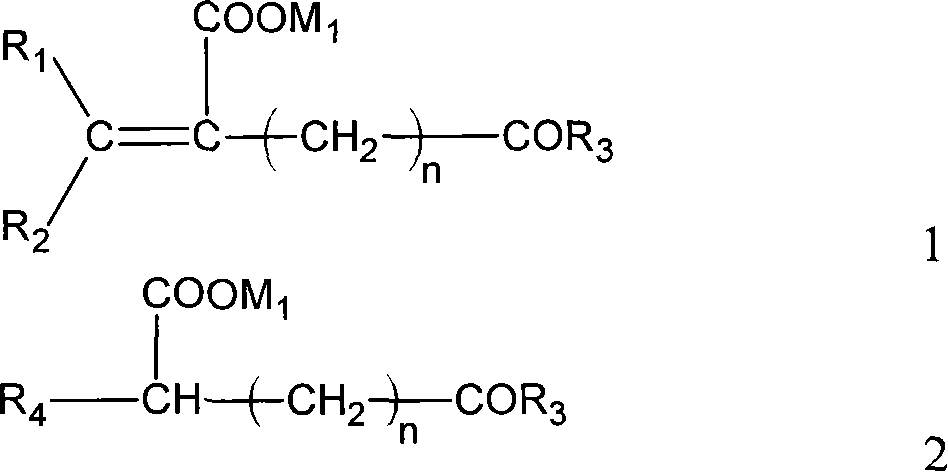

The purpose of the present invention is to provide a method for preparing a modified polyacrylic acid graft copolymer high-efficiency water reducer. By adding unsaturated dicarboxylic acid and its derivative monomers to adjust the polymerization activity of the copolymerization system, it is easy to obtain the structure and It is a graft copolymer with excellent performance, and adjusts the distribution of carboxyl groups on the main chain of the comb-like molecular structure, effectively improving the problem of poor dispersion and retention generally existing in traditional polyacrylic acid-based water reducers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for preparing a high-efficiency modified polyacrylic acid-graft copolymer water-reducing agent, and belongs to the field of water-reducing agent. The water-reducing agent is obtained by copolymerization of a mixture (a) of polyethylene glycol methyl ether methacrylate monomer and acrylic acid monomer, a monomer (b) of unsaturated dicarboxylic acid and derivative thereof or a mixture of unsaturated dicarboxylic acid and derivatives thereof, and a monomer (c) of unsaturated sulfonic acid or salt thereof, in the presence of persulfate as initiator, followed by neutralization with an alkaline solution. The invention utilizes comonomer of unsaturated dicarboxylic acid and derivatives thereof to control the polymerization activity of monomers in the copolymerization system and the distribution of carboxyl groups in the main chain of comb-like molecular structure, and efficiently overcomes the problem of poor dispersion and retention properties in the prior art. The synthetic water-reducing agent has the advantages of simple operation process, good dispersion and retention properties, low production cost, etc.

Description

A kind of preparation method of modified polyacrylic acid graft copolymer high-efficiency water reducer technical field The invention relates to the technical field of preparing a high-performance water-reducer for concrete, in particular to a specific synthesis method of a modified polyacrylic acid graft copolymer high-efficiency water-reducer. Background technique In recent years, with the vigorous development of my country's basic construction, the performance requirements for concrete superplasticizers have been continuously improved, and the research and development and engineering applications of polycarboxylate superplasticizers have increased year by year. Generally, polycarboxylate superplasticizers prepared using acrylic acid as the main raw material generally have poorer dispersibility and dispersion retention performance than those prepared using methacrylic acid as the main raw material. Since acrylic acid is cheaper than methacrylic acid, if acrylic acid can ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F220/06C08F290/06C04B24/16

Inventor 王子明李婷王晓丰崔素萍兰明章王亚丽

Owner JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com