Air-entraining monomer, air-entraining water reducing agent and preparation method thereof

A water reducer and monomer technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems of insufficient air-entraining effect of water reducers, so as to prolong the storage time and improve the retention time , the effect of reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

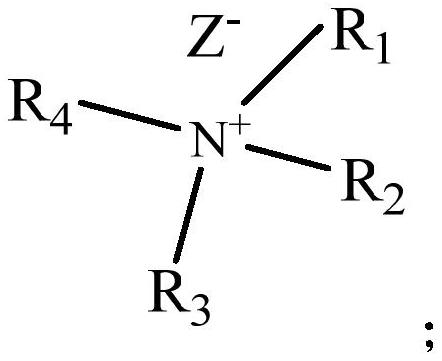

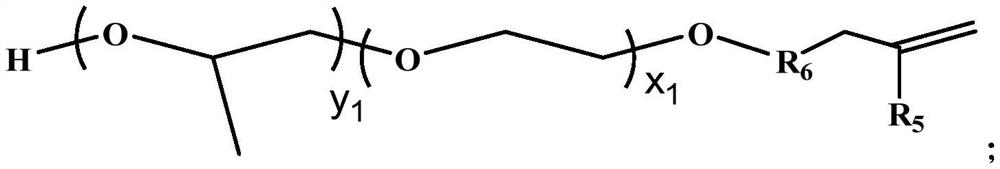

[0034] The invention provides a preparation method of an air-entraining polycarboxylate water reducer, comprising the following steps:

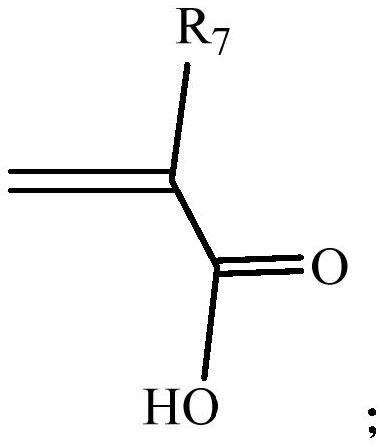

[0035] The ether macromonomer, reducing agent and appropriate amount of deionized water are placed in the reactor, stirred and dissolved, and the mixed solution of unsaturated acid and unsaturated ester, air-entraining monomer solution, oxidant and chain are added dropwise to the reactor. transfer agent, and adjust the temperature to 25-50 ℃ to carry out the reaction, the dropwise addition time is 1-3h, after the dropwise addition, the temperature is kept for 0.5-1.5h, after the reaction is completed, the temperature is lowered to room temperature, and the pH is adjusted to 6-7 with liquid caustic soda, i.e. Obtain air-entraining water reducing agent;

[0036] Wherein, the mass ratio of the ether macromonomer, the air-entraining monomer, the unsaturated acid, and the unsaturated ester is: 200: (1-30): (10-30): (1-10);

[0037] The ether macr...

Embodiment 1

[0051] (1) Preparation of air-entraining monomer B1: 0.1 mol of bis(hydroxyethyl) methyl dodecyl ammonium chloride, 0.1 mol of acryloyl chloride, 40 mL of 1,4 dioxane, and 0.1 mol of pyridine were placed in the reaction The product was purified by vacuum distillation and recrystallization to obtain the air-entraining monomer B1 under the condition of 15 ℃ in the reactor for 10 hours.

[0052] (2) Copolymerization: by weight, 200 parts of isopentenyl polyoxyethylene ether-2400, 1.5 parts of sodium formaldehyde sulfoxylate and deionized water are placed in the reactor, stirred and dissolved, and added to the reactor. Add dropwise the mixed solution of 20 parts of acrylic acid, 2 parts of 2-methacryloyloxyethyl phosphate and 3 parts of air-entraining monomer B1, 2 parts of hydrogen peroxide solution, 1 part of thioglycolic acid solution, dropwise at 25°C The time is 3h, the temperature is kept for 1h after the dropwise addition is completed, the temperature is lowered to room tem...

Embodiment 2

[0054] (1) Preparation of air-entraining monomer B2: 0.1 mol of octadecylbis(2-hydroxyethyl)methylammonium chloride, 0.1 mol of acryloyl chloride, 45 mL of 1,4 dioxane, and 0.1 mol of pyridine were placed In the reactor, the reaction was carried out at 15°C for 10 hours, and the product was purified by vacuum distillation and recrystallization to obtain the air-entraining monomer B2.

[0055] (2) copolymerization reaction: in parts by weight, 200 parts of isopentenyl polyoxyethylene ether-2400, 1 part of Brüggolit FF6 and deionized water were placed in the reactor, stirred and dissolved, and 21 parts were added dropwise to the reactor. A mixed solution of acrylic acid, 3 parts of 2-methacryloyloxyethyl phosphorylcholine and 4 parts of air-entraining monomer B2, 2 parts of hydrogen peroxide solution, 1 part of thioglycolic acid solution, added dropwise at 45°C for 3 hours, dropwise added After the reaction is completed, the temperature is kept for 1 h, and after the reaction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com