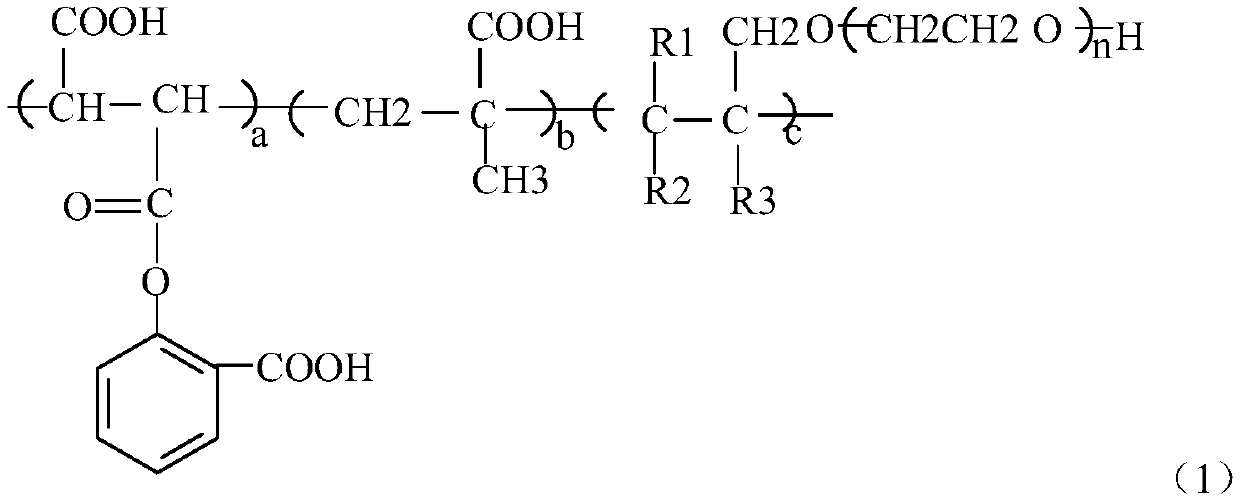

A kind of viscosity reducing type polycarboxylate water reducing agent and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in cement dispersant, polycarboxylate water reducer and its preparation field, which can solve the problems of poor adaptability of cement and aggregate, unsatisfactory viscosity reduction effect, high synthesis cost, etc. , to achieve the effects of heating-free, improving hydrophilicity and lipophilicity, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

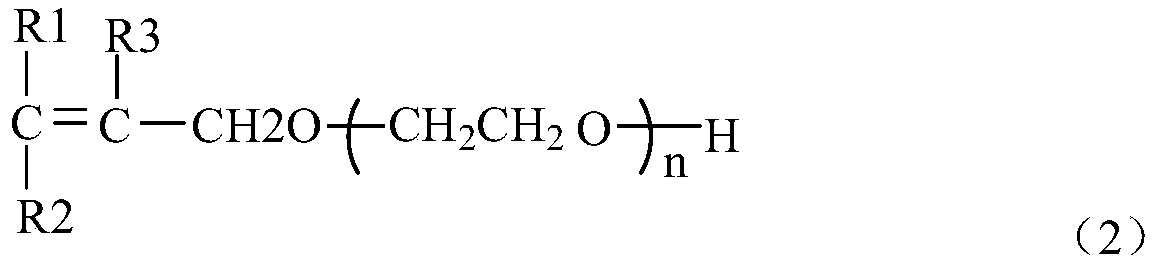

Method used

Image

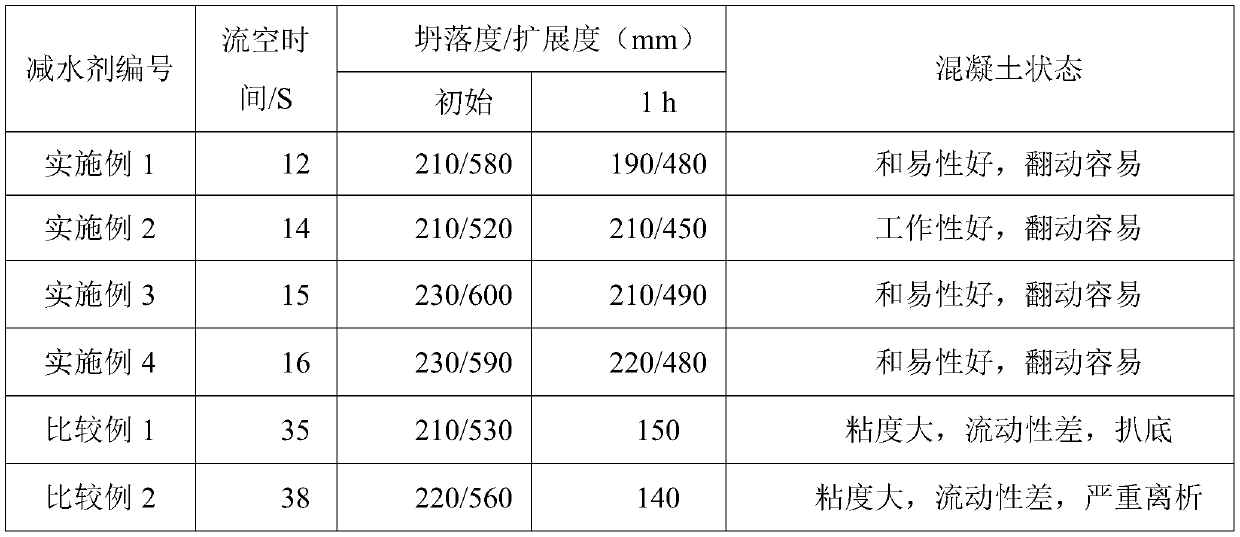

Examples

Embodiment 1

[0037] Example 1: To simplify the description, HPEG23, 50 and TPEG23, 50 respectively represent methallyl polyoxyethylene glycol and isopentenyl polyoxyethylene glycol with 23 and 50 ethylene oxide units; MAA represents Methacrylic acid; MAL means maleic anhydride; SC means salicylic acid; SA means mercaptopropionic acid; ester group-containing modified monomer MA-SC means the esterification of salicylic acid and maleic anhydride; (NH 4 ) 2 S 2 o 8 stands for ammonium persulfate; FAS stands for ferrous ammonium sulfate.

Synthetic example 1

[0039] Add 23g absolute ethanol (0.5mol), SC69g (0.5mol), 49g (0.5mol) maleic anhydride, catalyst p-toluenesulfonic acid 3.0g in the four-neck glass flask with thermometer, condenser and stirring device , the temperature was slowly raised to 40°C, and the reaction was continued for 3.0h at this temperature. After the reaction, 140 g of ester group-containing modified monomer MA-SC was obtained.

[0040] Example 1

[0041] Add 100g of deionized water into a four-necked glass flask with a thermometer, a condenser tube and a stirring device, turn on the stirring, add 107g of HPEG23 (0.1mol) to it, keep stirring, add 0.25g of FAS in the flask and stir for 15min, Start to add material A and material B with a metering pump. A material is 25.8g MAA (0.3mol), 2.36g MA-SC (0.01mol), 0.86g SA and 7.26g deionized water are made into the aqueous solution of mass fraction 80%; B material is 0.52g initiator (NH 4 ) 2 S 2 o 8 9.88 g of deionized water was added to the solution to form ...

Embodiment 2

[0043]Add 100g of deionized water into a four-necked glass flask equipped with a thermometer, condenser and stirring device, turn on the stirring, add 108.8g of TPEG23 (0.1mol) to it, and keep stirring, add 0.42g of FAS to the flask and stir for 15min , Start adding material A and material B with a metering pump. A material is 21.5g MAA (0.25mol), 4.72g MA-SC (0.02mol), 1.0gSA and 6.81g deionized water are made into the aqueous solution of mass fraction 80%; B material is 0.85g initiator (NH 4 ) 2 S 2 o 8 Add 16.15 g of deionized water to the solution to form an aqueous solution with a mass fraction of 1.5%. Add material A in 3.0 hours, and add material B in 3.5 hours. After adding material A, keep it at this temperature for 1.0 h, neutralize it with 30% NaOH to pH=6-7, and add a certain amount of water to obtain product 2 with a mass fraction of 40% polycarboxylate water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com