Spinning apparatus with air injection whirling current for lowering fibre

A vortex spinning and low-falling technology, which is applied in the textile field to achieve the effects of less hairiness, lower production costs, and lower fiber toff rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

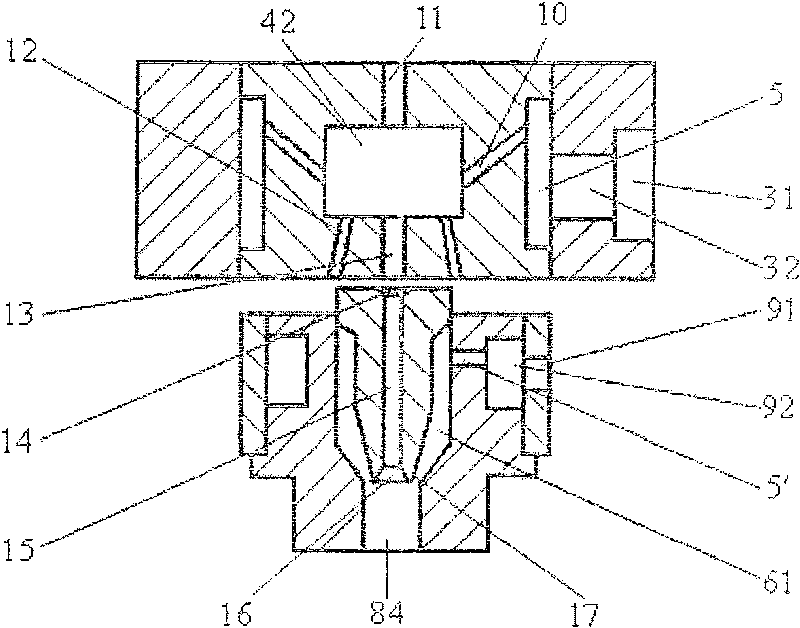

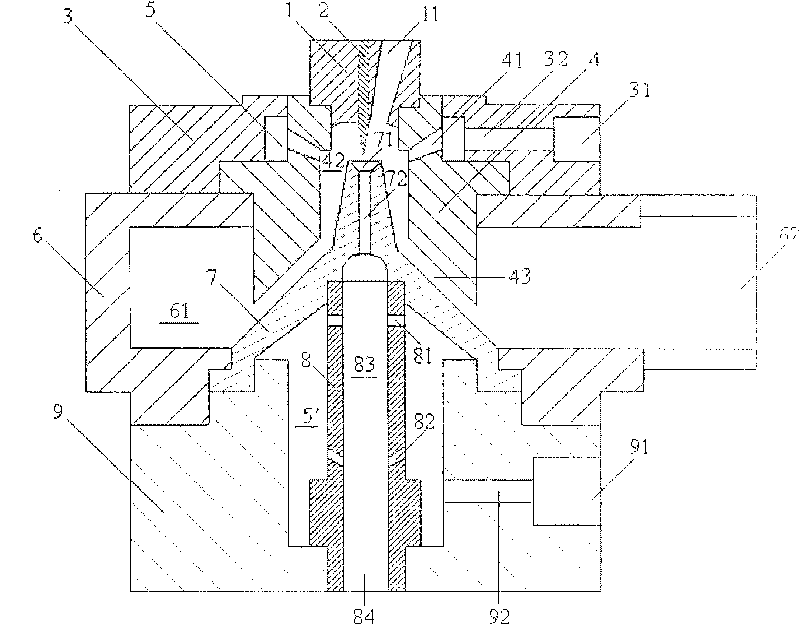

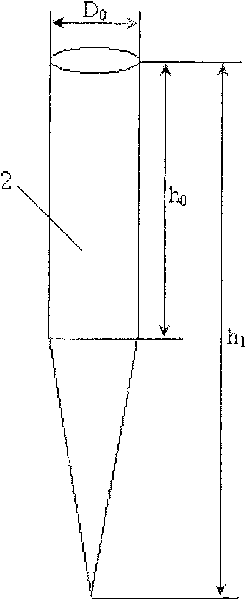

[0029] Such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention is installed between the drafting zone and the winding zone of the spinning machine. The low-noil air-jet vortex spinning device includes a guide pipe 1, an air storage cover 3, a twisting nozzle 4, a first air storage chamber 5, a second air storage chamber 5', an exhaust cover 6, a vortex tube 8, a vortex The tube support 9 is characterized in that it also includes a set guide needle 2, which is fastened on the guide tube 1, its upper part is cylindrical, and its lower part is conical. The cylindrical diameter of the guide needle 2 is D 0 0.3 ~ 0.6mm, the upper height h of the guide needle 2 0 6.5~7.5mm, the total height h of guide needle 2 1 The upper part of the twisting nozzle 4 is connected with the guide pipe 1 and the gas storage cover 3, and the middle part is connected with the gas storage cover 3 and the exhaust cover 6. The diameter of the inner hole of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com