LED lighting lamp

A technology for LED lighting and LED chips, applied in lighting devices, lighting auxiliary devices, lighting and heating equipment, etc., can solve the problem of increasing thermal resistance, limited service life, and not fundamentally solving the problem of heat dissipation of power LED devices, etc. problems, to achieve the effect of improving heat dissipation performance and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

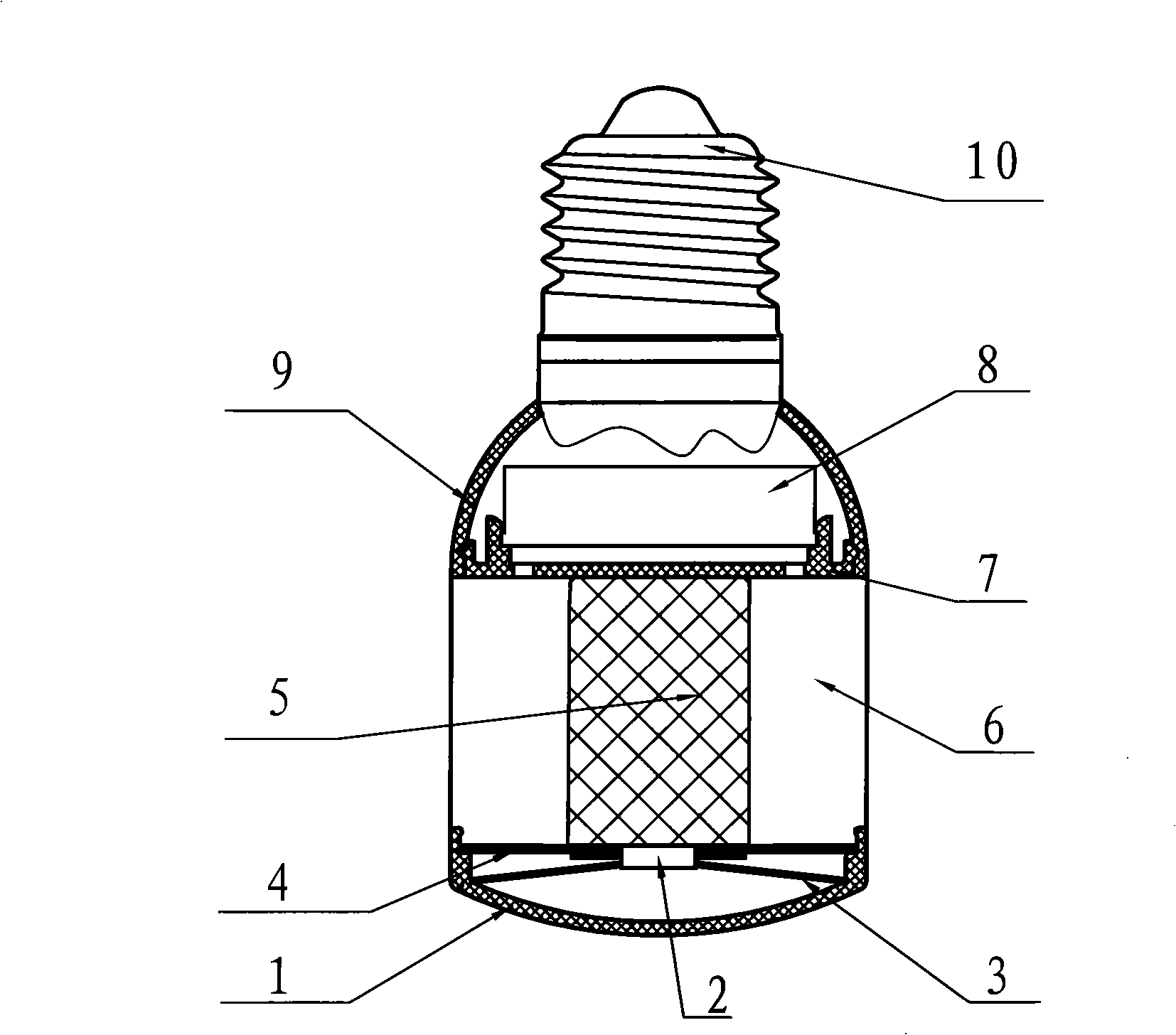

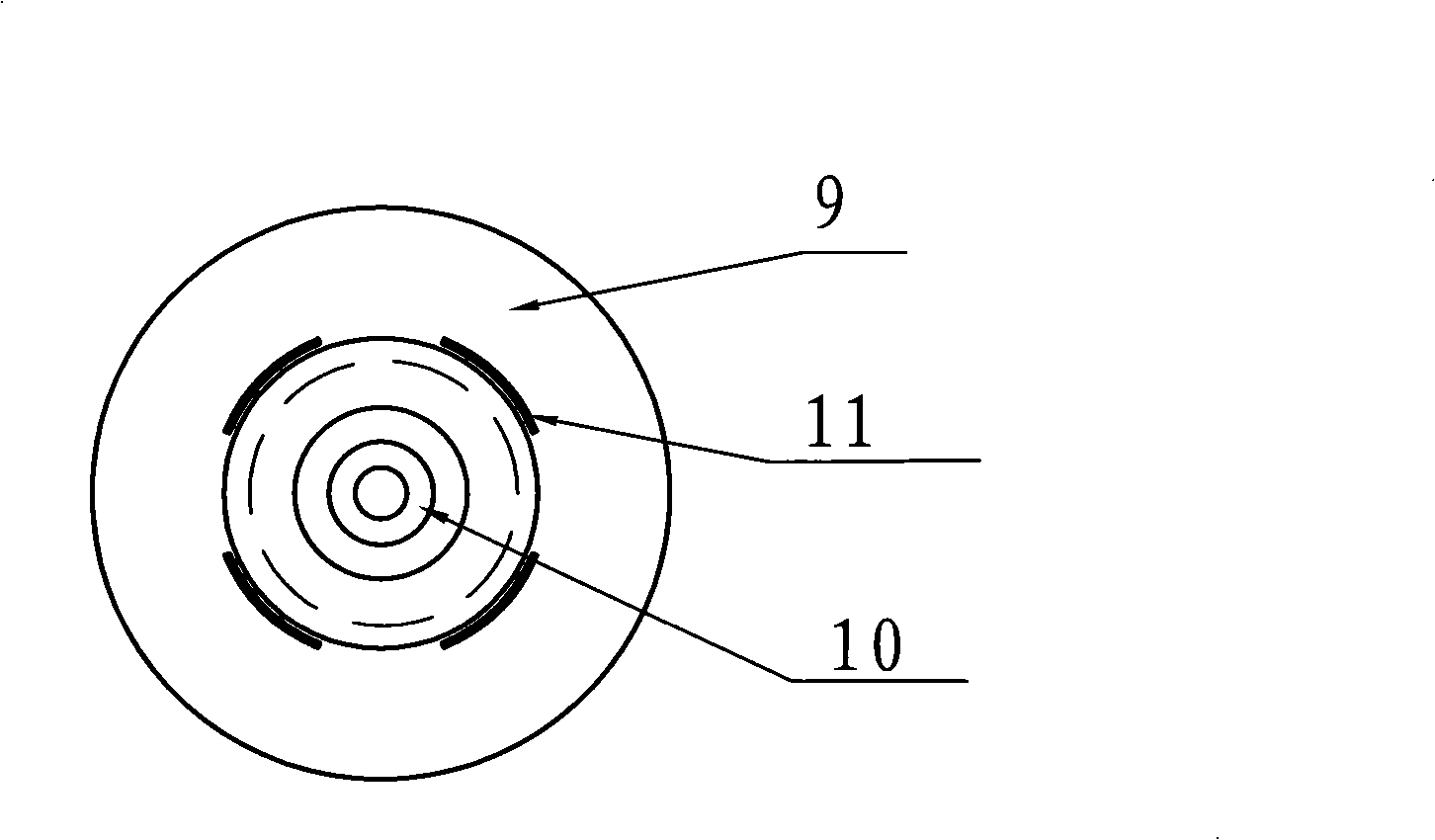

[0035] The LED illuminating lamp of the present invention is as figure 1 As shown, it is mainly composed of three parts: the light source part, the heat sink and the power supply part, among which:

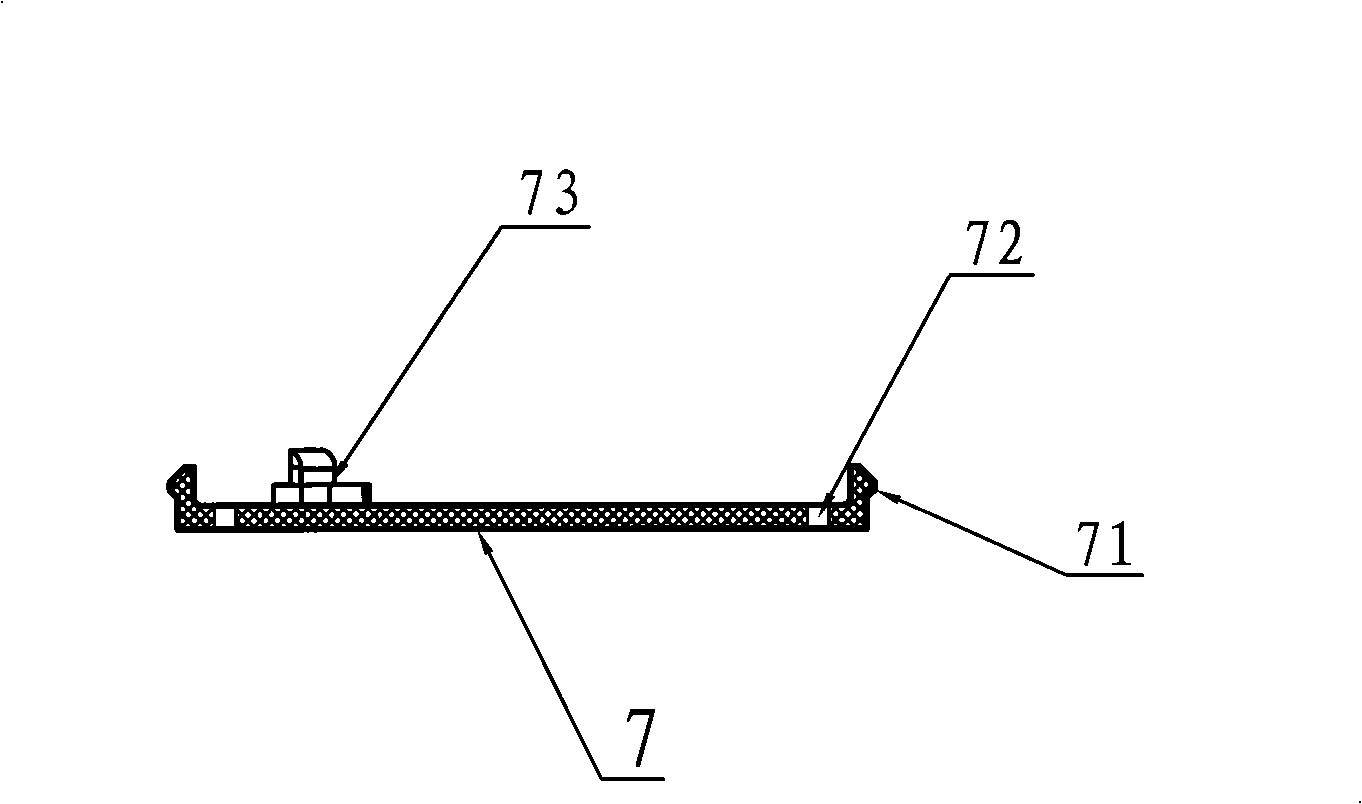

[0036] The heat sink is made of metal aluminum and consists of a solid heat sink base 5 and a plurality of fins 6 radially surrounding the heat sink base 5 for conducting the heat energy generated by the LED lighting to the surrounding air. The fins 6 of the radiator can be made into various shapes that are conducive to increasing the effective heat dissipation area of the radiator, such as Figure 5 The fork-shaped wings shown and the Figure 6 T-shaped wings shown.

[0037] The two end faces of the radiator base 5 are smooth planes, and two through grooves 51 for placing wires are longitudinally arranged on the radiator base 5, and two screw fixing holes 52 are respectively provided on the two end faces, as Figure 5 , Figure 6 shown.

[0038] The light source part is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap