Method for choosing exposure parameter by using X ray exposure equation

A technology of exposure parameters and X-rays, which is applied in the direction of material analysis, optics, and instruments using radiation, and can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

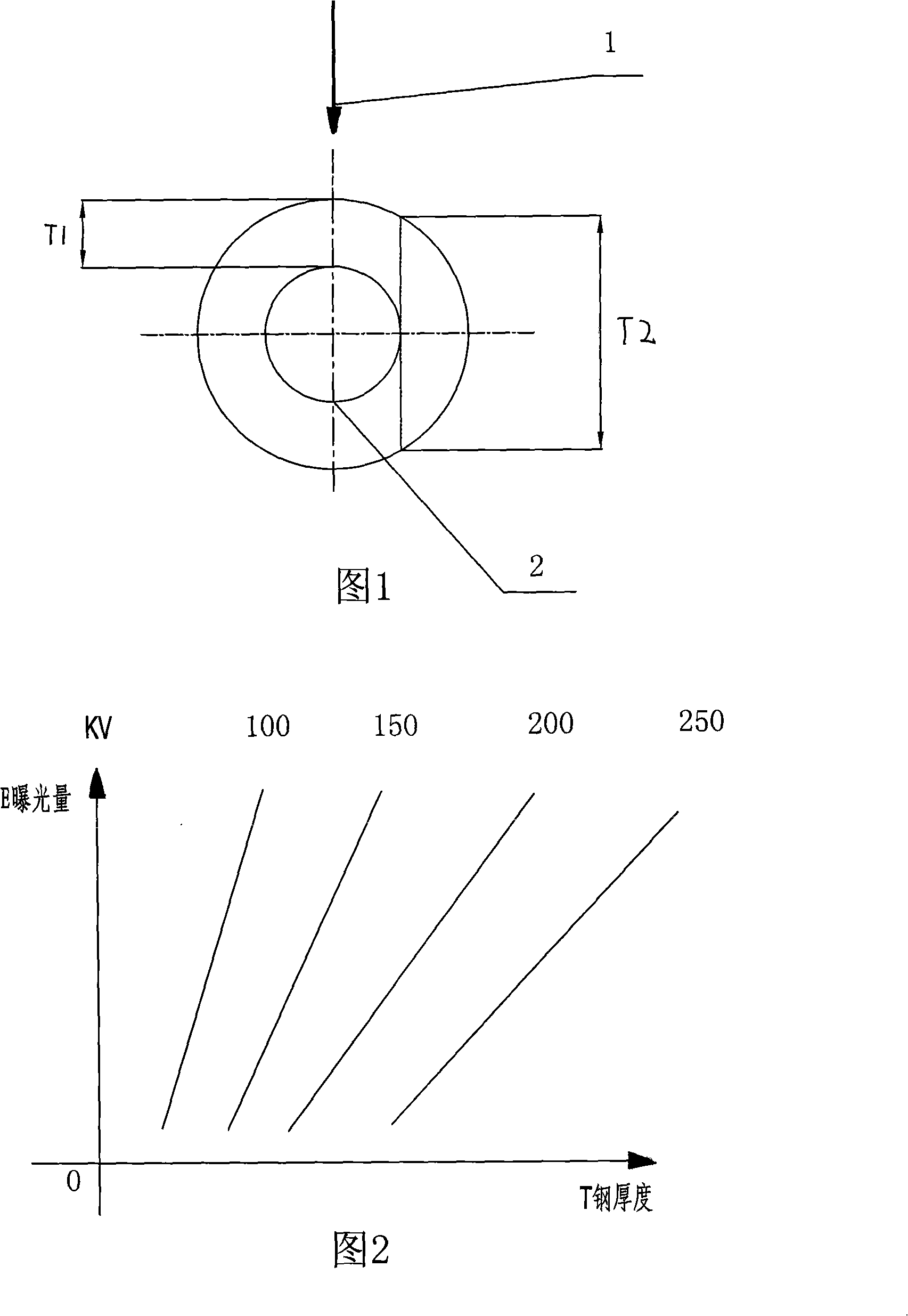

[0027] 1.1 Technical Difficulty in X-ray Inspection of Girth Weld of Small Diameter Pipe

[0028] 1.1.1 Theoretical Analysis of Technical Difficulty

[0029] (1) The difference between the flat stepped test block and the circular arc surface of the small-diameter pipe girth weld

[0030] Whether it is tube voltage-transillumination thickness (KV-T) type exposure curve, or exposure amount-transillumination thickness (E-T) type exposure curve, all are by changing exposure parameters (for example, fixed tube voltage KV, changing exposure amount E ; Or fix the exposure amount E, change the tube voltage KV), and transilluminate the flat ladder test blocks made of different fixed thicknesses. The object of X-ray flaw detection is the girth weld of small-diameter pipes, and the transillumination thickness of the arc surface changes continuously. Using the exposure curve made by the plane step test block for the circular arc surface of the small-diameter pipe girth weld, and selecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com