Multi-electrode test probe direct dipping fast assessing method for anti-rust performance of soft membrane antirust oil

A technology of anti-rust performance and anti-rust oil, applied in the direction of measuring devices, electrochemical variables of materials, instruments, etc., can solve the problems of long test period, rough evaluation, heavy equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

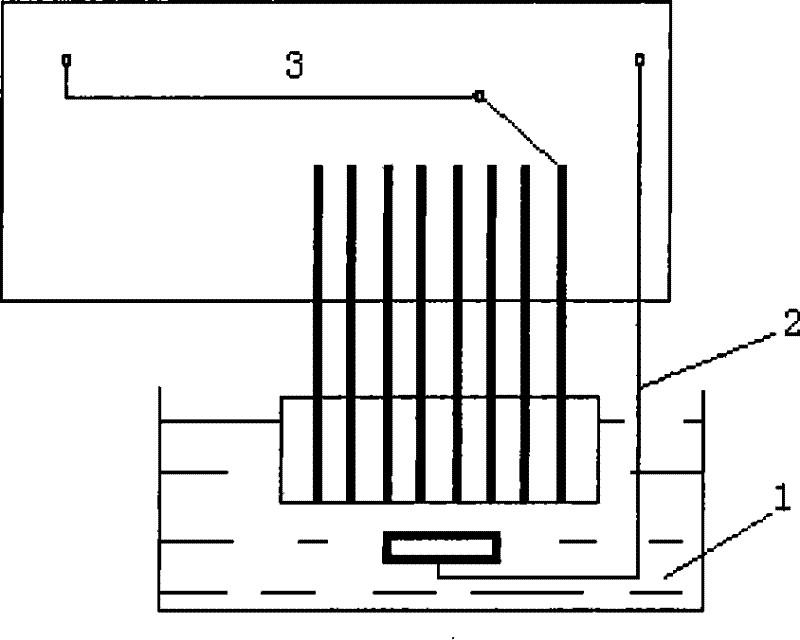

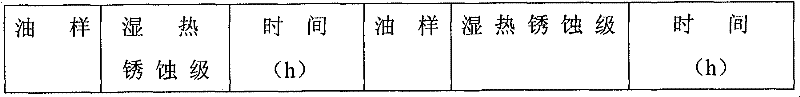

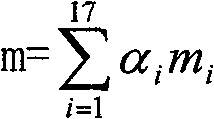

[0026] 64 wire electrodes of Fe (or Cu, Al) base materials with a diameter of 0.9mm are evenly arranged at a distance of 2.5mm, and are insulated from each other by casting epoxy resin to make a test probe; the auxiliary electrode material is the same as the test electrode. During the test, grind the working surface of the test probe and the auxiliary electrode, clean and dry them with petroleum ether, absolute ethanol, etc., put them into the anti-rust oil at a fixed distance, and connect the other end to the tester, such as figure 1 shown. Tested after 10 minutes of deposition, the resistance distribution of 64 electrodes can be obtained (R i ≥1×10 8 Ω). Calculate m, ,δ. Compare m first, the smaller one has better anti-rust performance; if m is the same, compare The larger one has better anti-rust performance; if m, In the same way, comparing δ, the smaller one has better anti-rust performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com