Tapered roller bearing

A technology for tapered roller bearings and raceways, which is applied in the field of tapered roller bearings, can solve the problems of not being good, and the lower limit of the gap between the cage and the raceway ring is not disclosed, so as to prevent the decline of life and the increase of interference force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the tapered roller bearing of the present invention will be described below. The same symbols are used to mark the same or equivalent parts, and sometimes they will not be repeated.

[0030] (Embodiment 1)

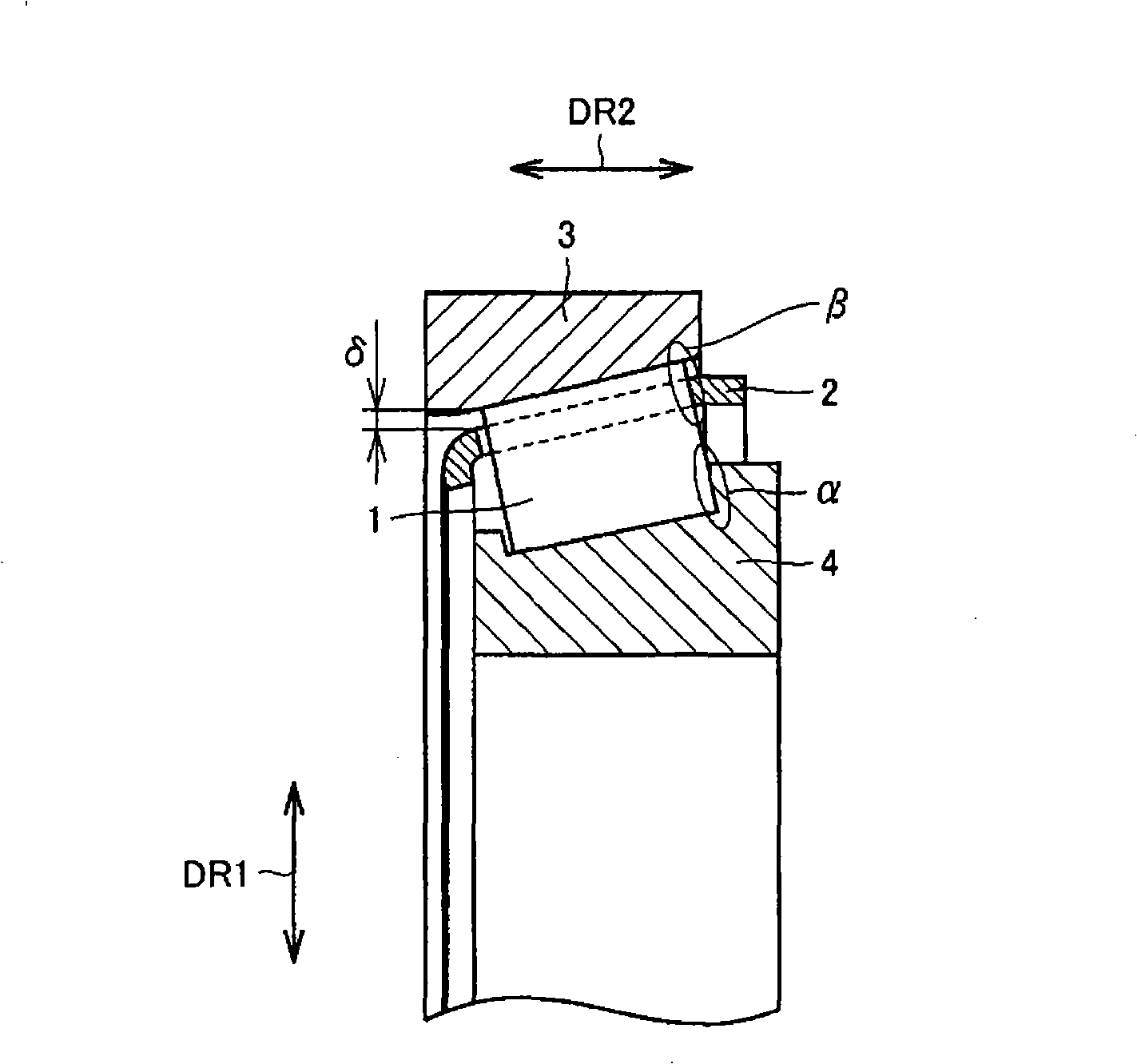

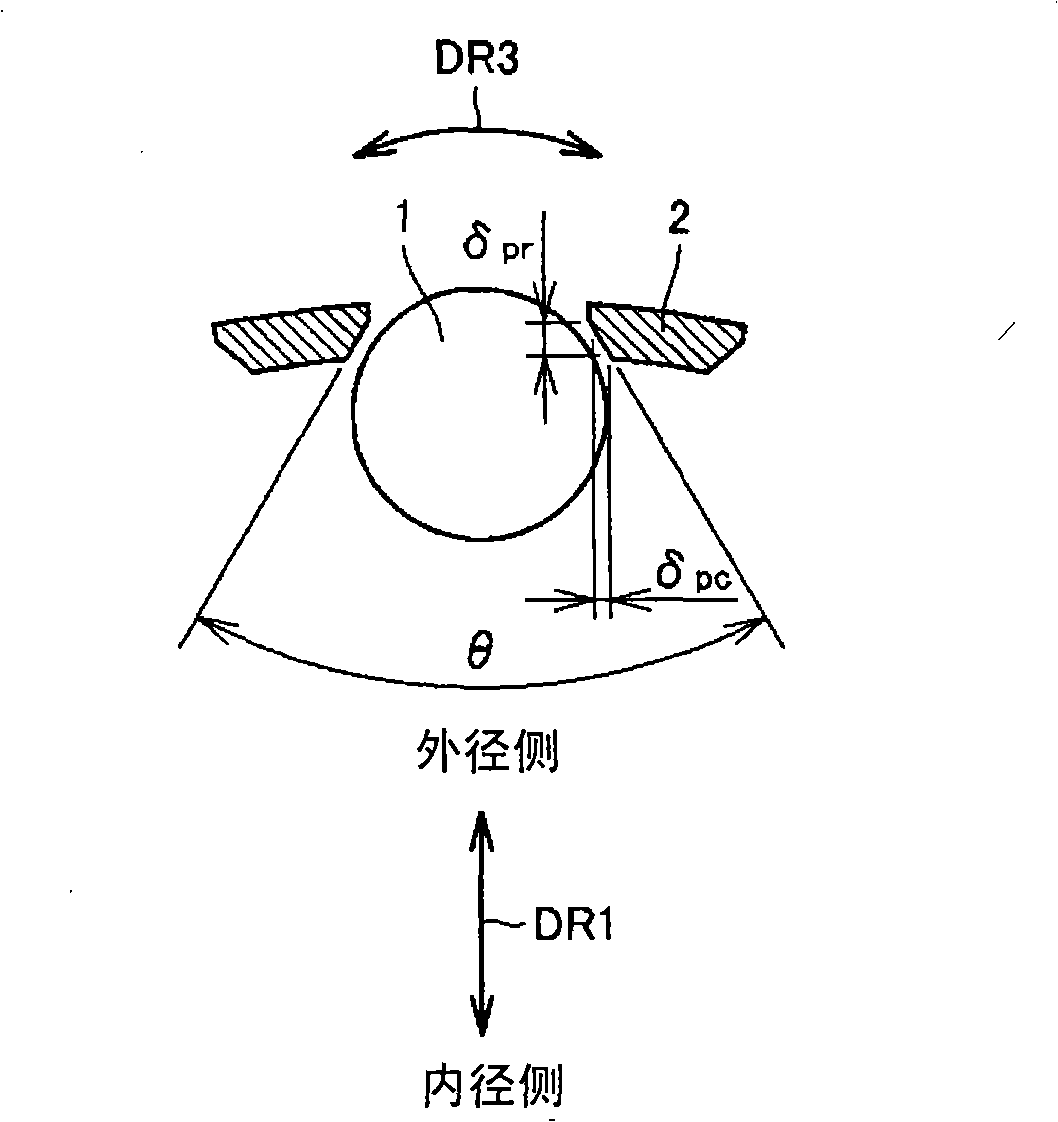

[0031] figure 1 It is a sectional view showing the tapered roller bearing according to Embodiment 1 of the present invention. exist figure 1 Among them, the arrow DR1 indicates the radial direction of the bearing, and the arrow DR2 indicates the axial direction of the bearing. refer to figure 1 , The tapered roller bearing of this embodiment includes: a roller 1 as a "rolling element", a cage 2 with a pocket for holding the roller 1, and an outer ring 3 and an inner ring as a "raceway ring". 4. Roller 1 rolls between outer ring 3 and inner ring 4 . The cage 2 is formed of, for example, iron. The cage 2 is disposed near the outer ring 3 .

[0032] exist figure 1 middle,

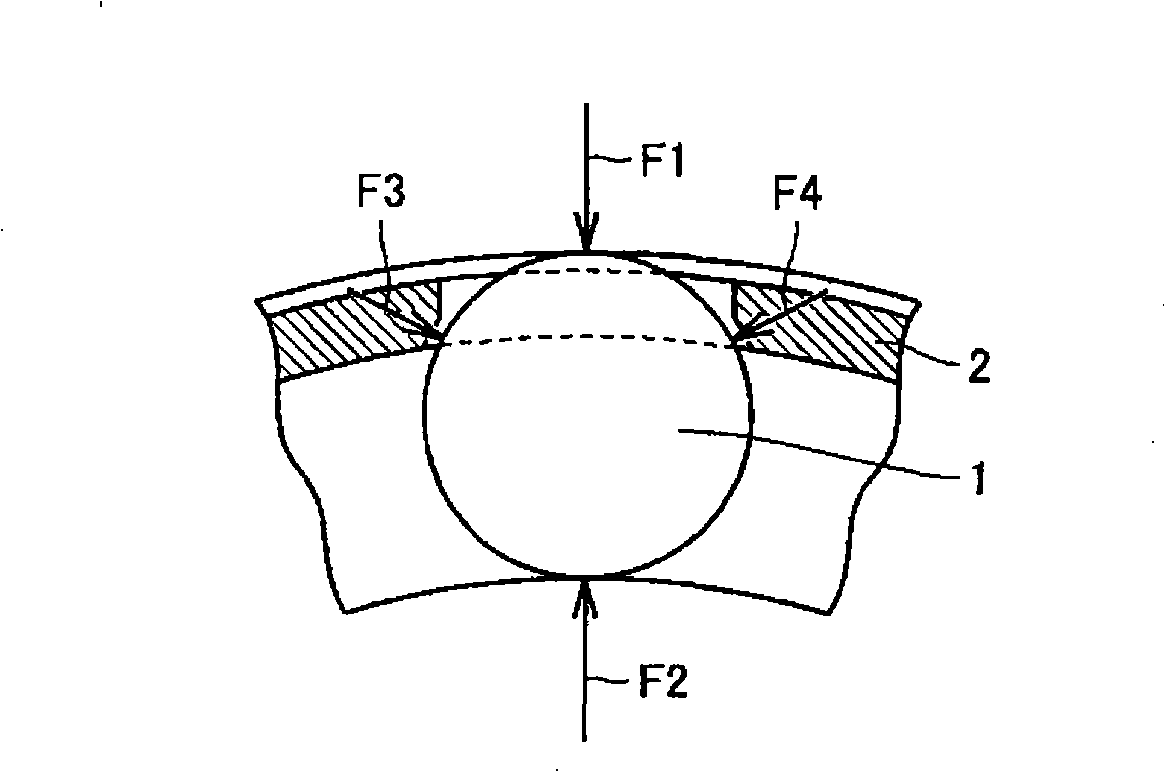

[0033] (A) The rolling surface of the roller 1 is in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com