Method for testing cycle life of rechargeable battery

A cycle life and recharging technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of degradation of charge and discharge capacity, no reliable test method, and reduction of the time required for testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

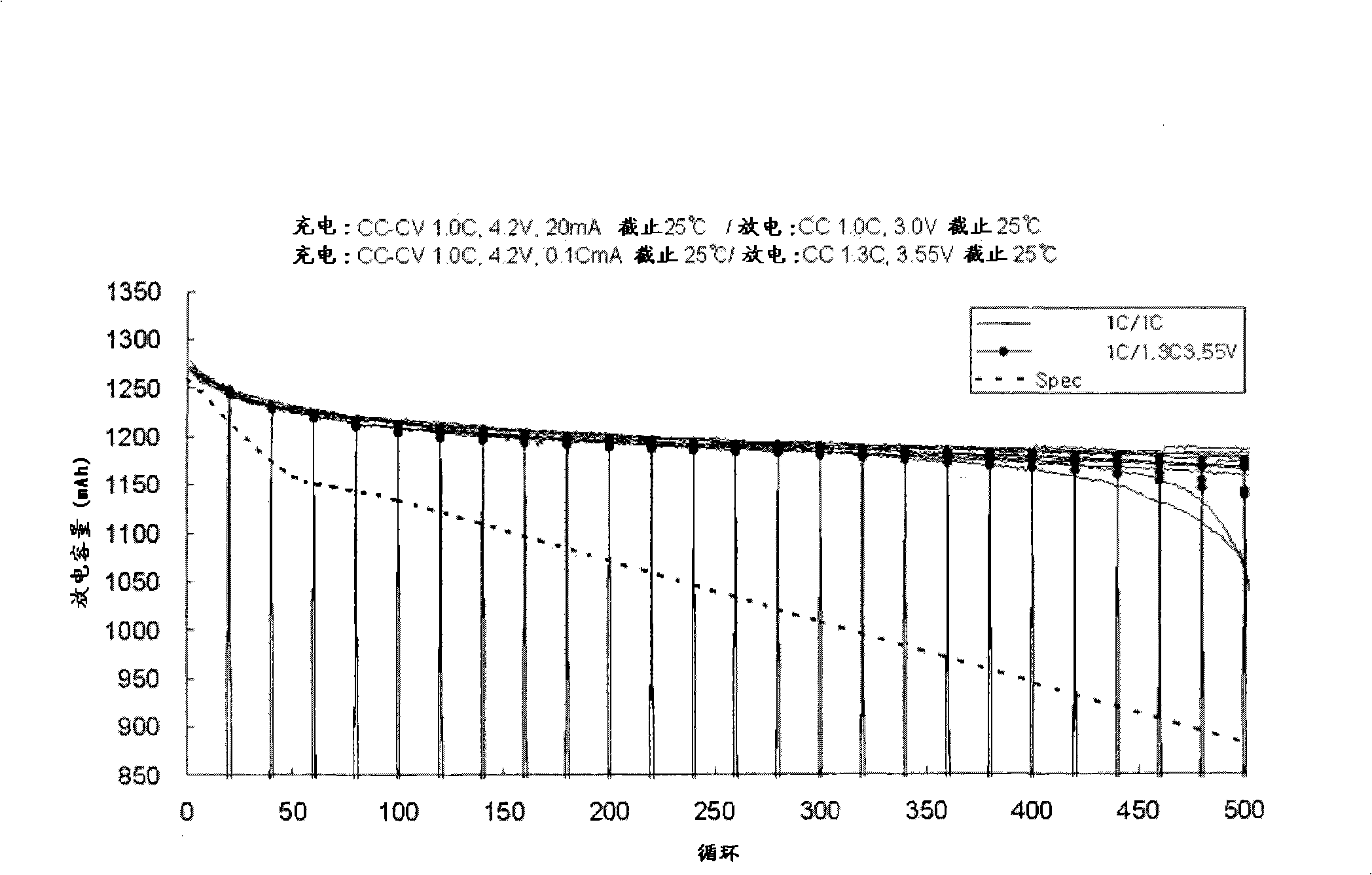

[0056] Embodiment 1: condition 8 of Fig. 6

[0057] Under the conditions of a charge rate of 1.5C, a charge cut-off current of 0.1C, and no charge-discharge recovery period in a normal charge-discharge method, it took 20 days to conduct a cycle life test with 500 cycles.

Embodiment 2

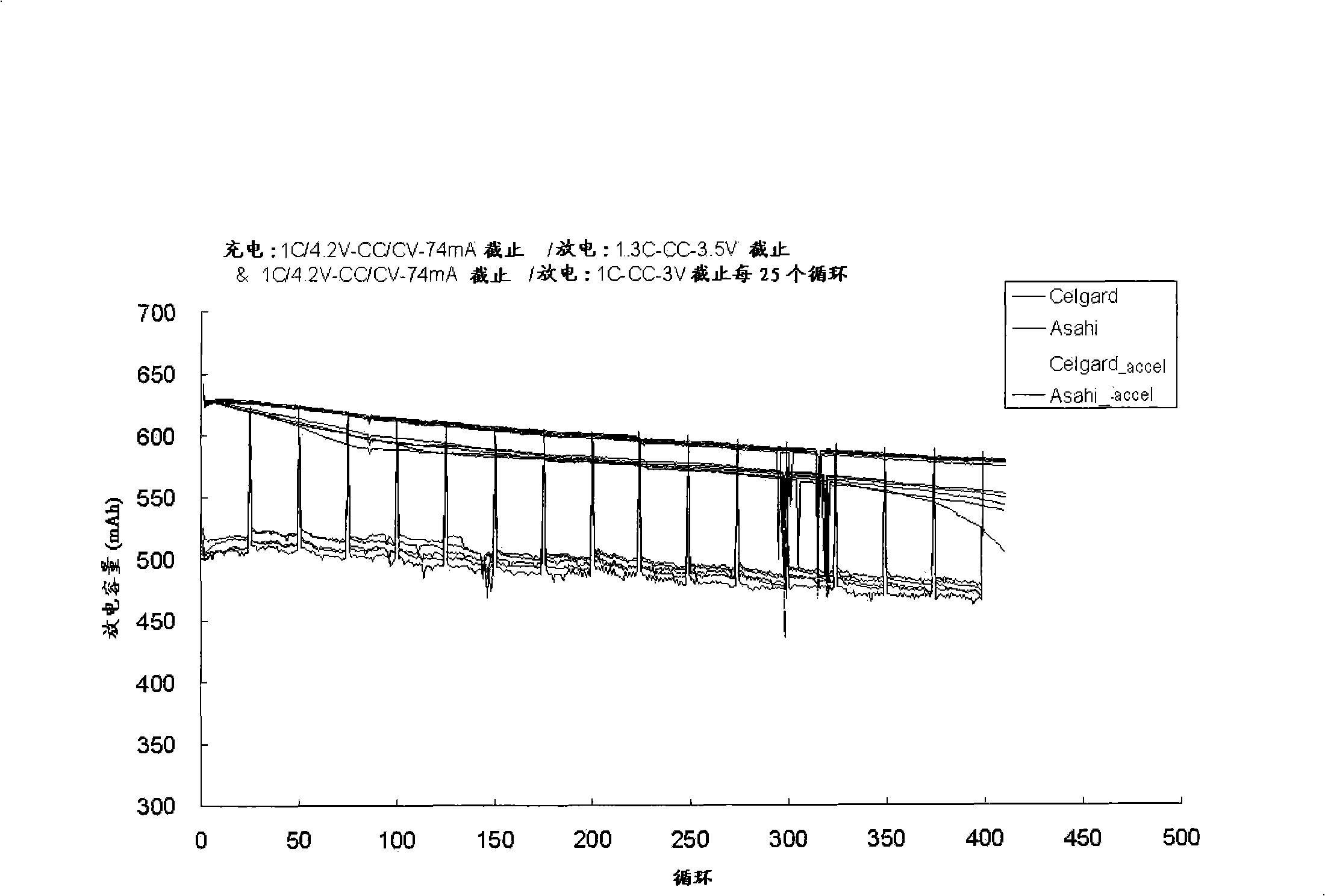

[0074] Example 2: Condition 13 of Figure 6

[0075] It took 41 days to conduct a cycle life test with 500 cycles under the conditions of a charge cut-off current of 0.1C, a discharge rate of 1.3C, a discharge cut-off voltage of 3.3V, and no charge-discharge recovery period in a normal charge-discharge method.

Embodiment 3

[0082] Embodiment 3: condition 14 of Fig. 6

[0083]It took 32 days to conduct a cycle life test with 500 cycles under the conditions of a charge cut-off current of 0.1C, a discharge rate of 1.3C, a discharge cut-off voltage of 3.55V, and no charge-discharge recovery period in a normal charge-discharge method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com