Module and electronic device

An electronic device and intermediate position technology, applied in the field of electronics, can solve the problems of cumulative tolerance of the dimension chain and the difficulty of guaranteeing pin coplanarity, and achieve the effect of eliminating the cumulative dimensional error, reducing the layout space, and improving the coplanarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

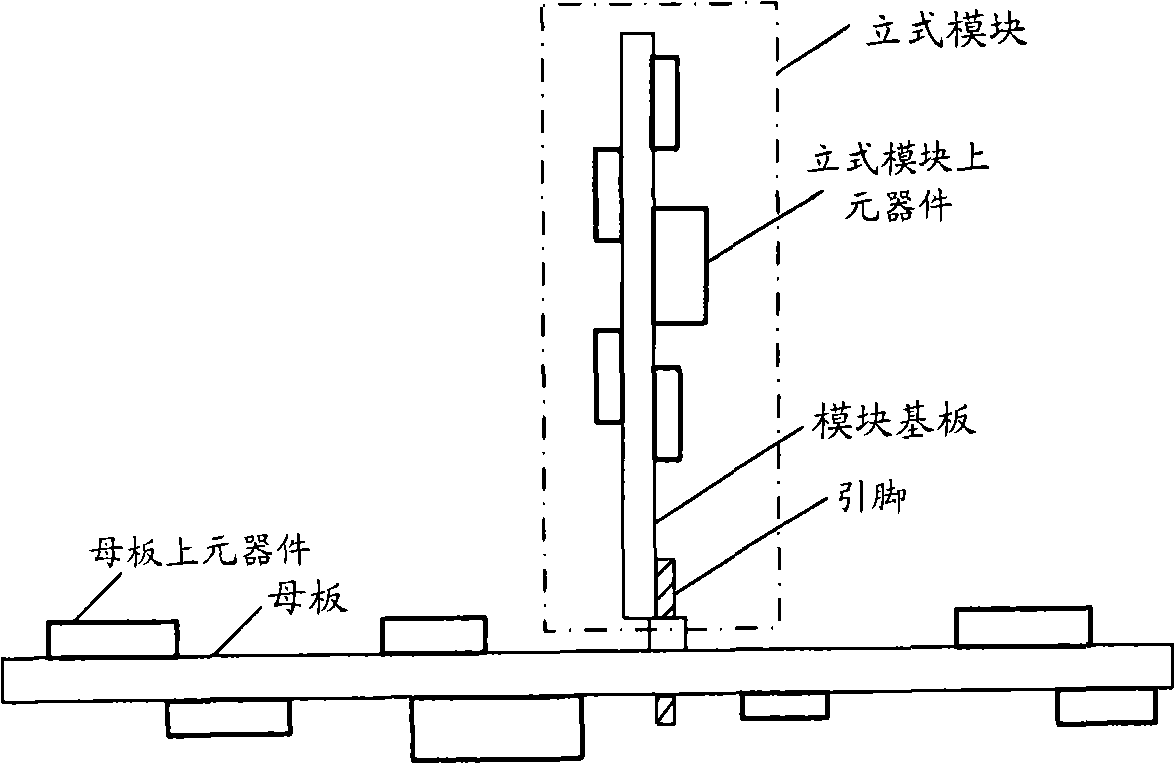

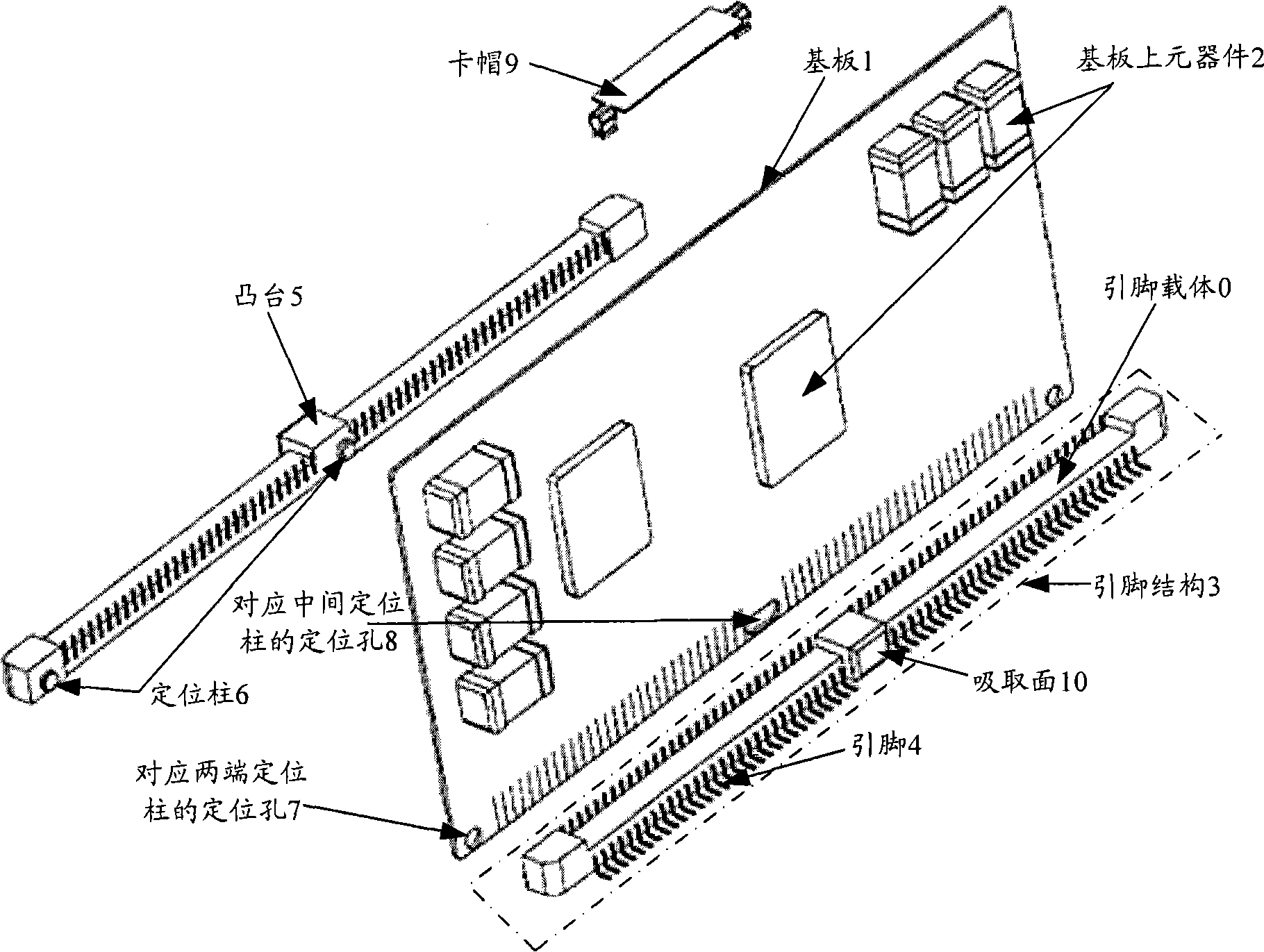

[0036] The module of the present invention mainly includes a substrate and a pin structure.

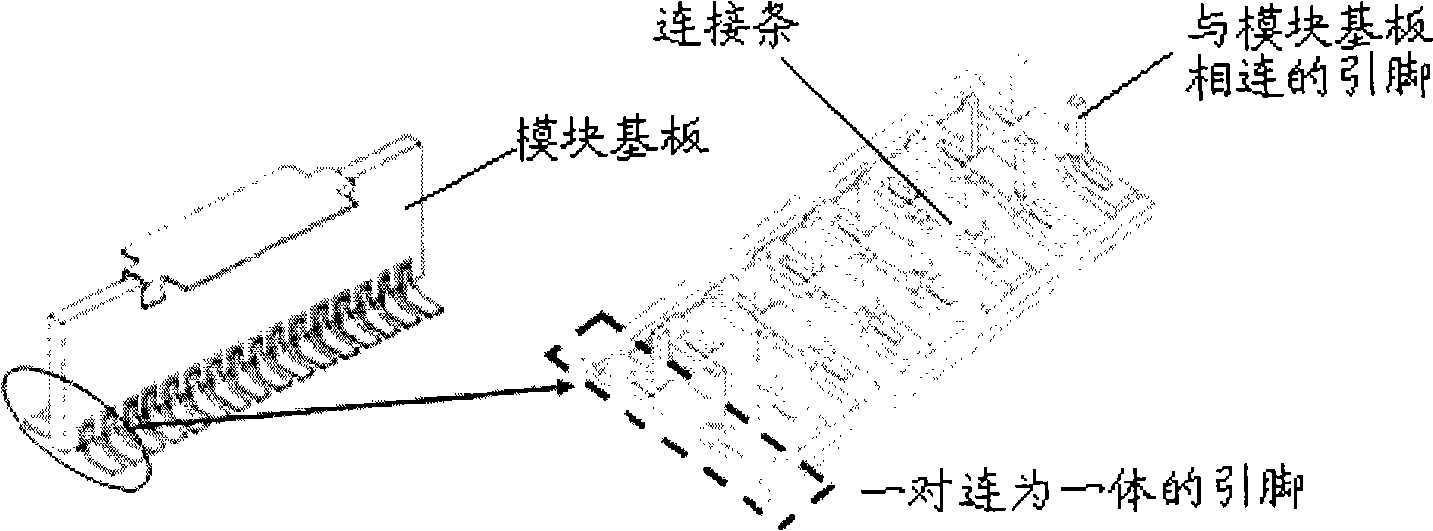

[0037] Wherein, the pin structure includes a pin and a pin carrier; the pins are independently mounted on the pin carrier; the pin structure is at least two, which are respectively arranged on both sides of the substrate for connecting the substrate and motherboard;

[0038] When the substrate is relatively long, two or more pin structures can be respectively arranged on the same side of the substrate to improve the stability of the connection between the substrate and the motherboard.

[0039] The pin carrier is provided with at least two positioning columns, and the substrate is provided with positioning holes corresponding to the positioning columns provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com