High intensity sweeteners and coloring agent compositions

A high-intensity sweetener, composition technology, applied in food science, function of food ingredients, confectionery industry, etc., can solve problems such as loss, attention deficit and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Using a Turbula T2F dry powder mixer (WAB AG, Basel, Switzerland), mixing at 32 rpm for 5 minutes, prepared in 2 quart metal screw cap glass bottles containing a certain amount of ® non-caloric sweetener and the composition of the present invention shown in Table 2.

[0075]

[0076] Table 2:

[0077] brand non-caloric sweetener combined with FD&C Red No. 40 or FD&C Blue No. 1

[0078] Samples (triplicate) of each of the compositions shown in Table 2 were tested in dry and hydrated form using a Hunter Colorquest XE (Hunter Associates Laboratory, Inc., Reston, Virginia). The sample was hydrated by dissolving 0.493 g (about 1 teaspoon) of the composition in 236.58 g (about 8 ounces) of distilled water.

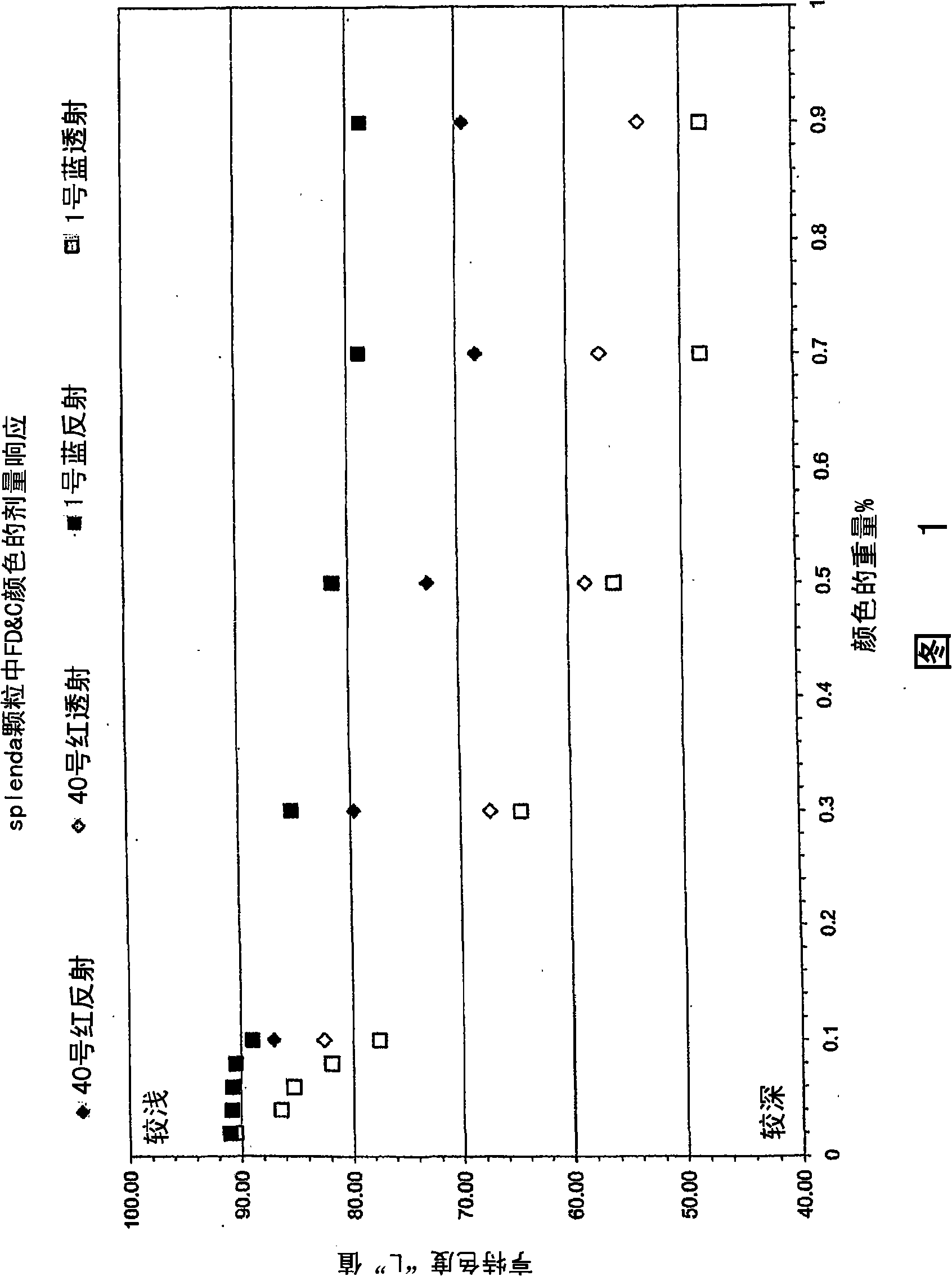

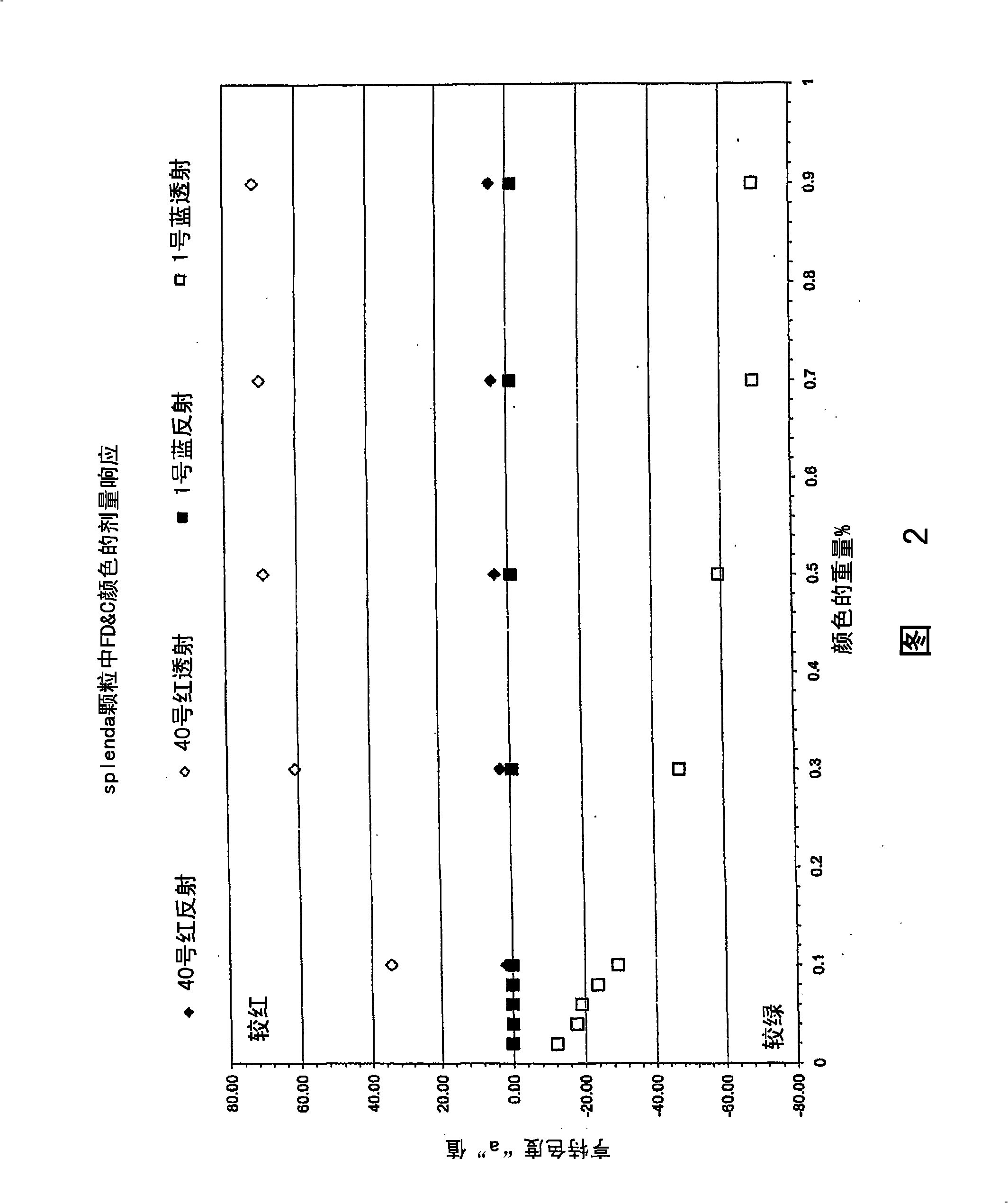

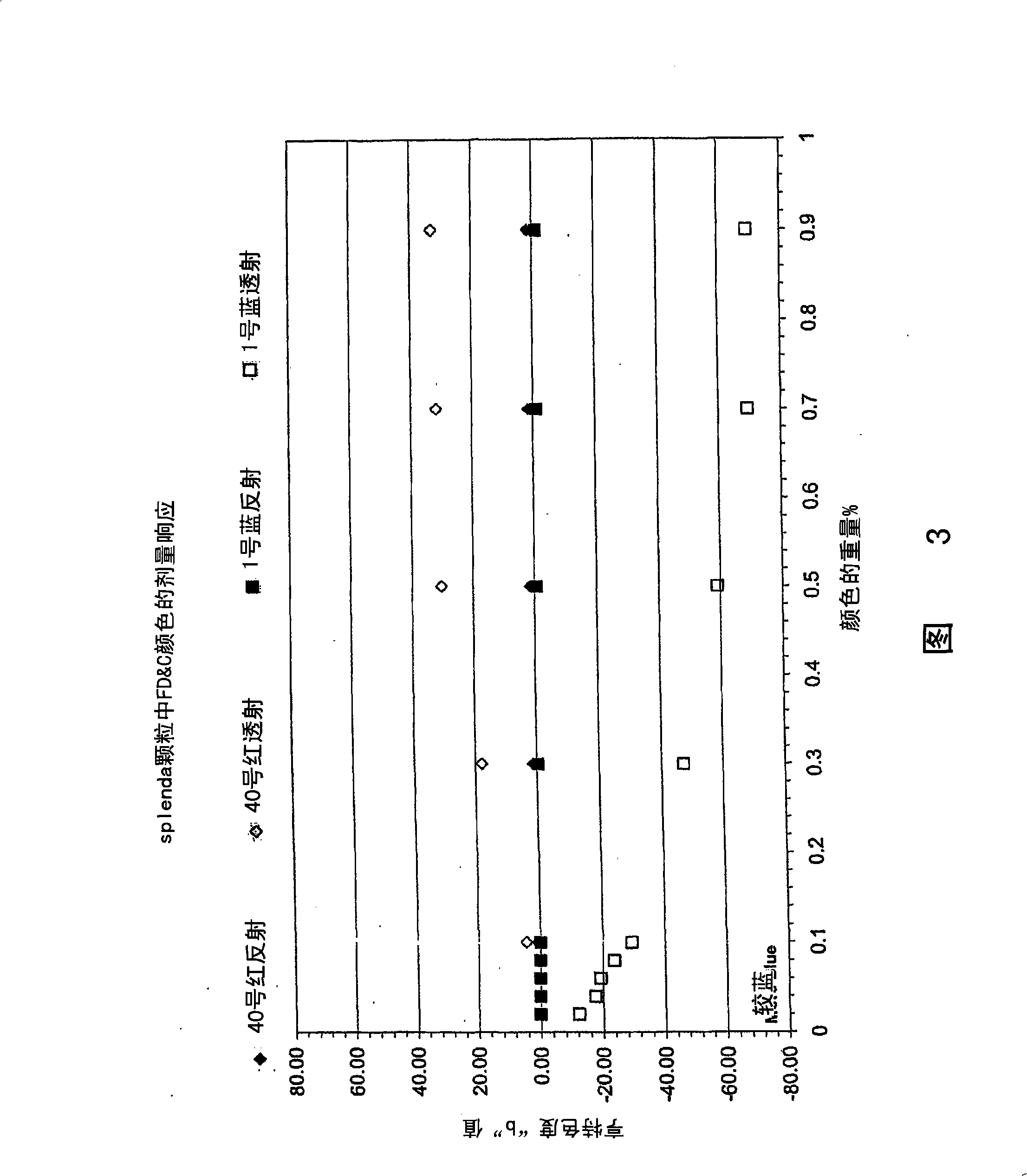

[0079] Although not visually significant at the lowest dose level, the Hunter Color L, a, and b values for the dry sample were lower than typical L, a, and b values for granulated sucralose at 92.72, -0.12, and 0.58, respectively (Wisconsin-Staley control, ti...

Embodiment 2

[0083] Using a Turbula T2F dry powder mixer, mix at 32 rpm for 5 minutes and prepare in a 2-quart metal screw cap glass bottle containing a certain amount of ® non-caloric sweetener and the composition of the present invention shown in Table 4.

[0084]

[0085] Table 4: brand non-caloric sweetener and FD&C No. 5 Yellow and No. 3 Green Composition

[0086] Samples (triplicate) of each of the compositions shown in Table 4 were tested in dry and hydrated form using the Hunter Colorquest XE. The sample was hydrated by dissolving 0.493 g (about 1 teaspoon) of the composition in 236.58 g (about 8 ounces) of distilled water.

[0087] The dose response of the compositions is shown in Table 5 below.

[0088]

[0089] Table 5: Dose Response of Sucralose Hydrate with FD&C No. 5 Yellow or FD&C No. 3 Green

Embodiment 3

[0091] Using a Turbula T2F dry powder mixer, mix at 32 rpm for 5 minutes and prepare in a 2-quart metal screw cap glass bottle containing a certain amount of ® non-caloric sweetener and the composition of the present invention of the two coloring agents shown in Table 6.

[0092]

[0093] Table 6: brand non-caloric sweetener and FD&C No. 5 Yellow and No. 3 Green Composition

[0094] Samples (triplicate) of each of the compositions shown in Table 6 were tested in dry and hydrated form using the Hunter Colorquest XE. The sample was hydrated by dissolving 0.493 g (about 1 teaspoon) of the composition in 236.58 g (about 8 ounces) of distilled water.

[0095] The dose response of the compositions is shown in Table 7 below.

[0096]

[0097] Table 7: Dose Response of Sucralose Hydrate with FD&C Yellow No. 6 and Green No. 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com