Stringpiece with bulb made of composite material

A technology of composite materials and balls, applied in the direction of joists, girders, trusses, etc., can solve the problems of easy damage, increased delamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

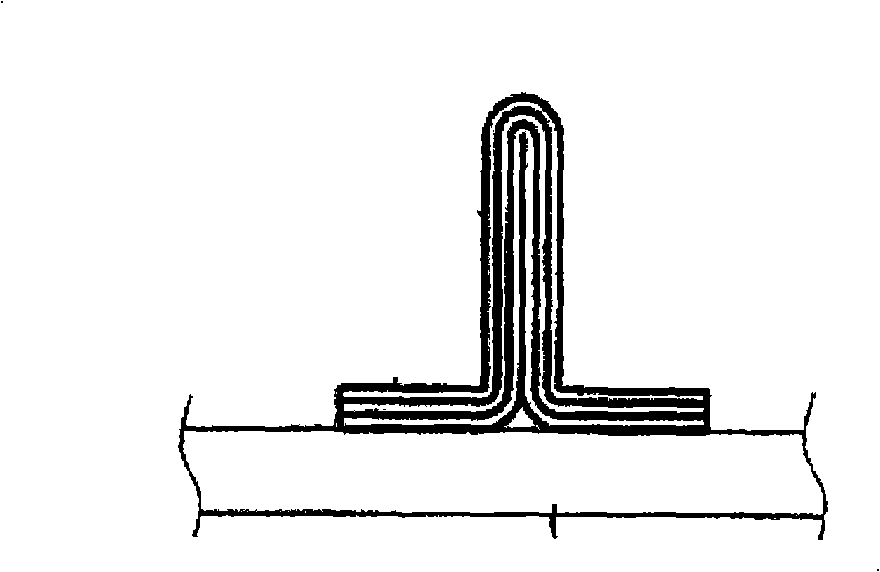

[0030] First the T-stringer 11 will be discussed.

[0031] These stringers 11 are formed by: webs 13, which are elongated sections perpendicular to the feet (or perpendicular to the panels) of the stringers 11; out) contact and function as a means of connecting the panel to the stringer; and a stiffener 17 arranged at the end of the web 13 opposite to the foot 15, the stiffener 17 forming a terminal portion having the shape of a bulb .

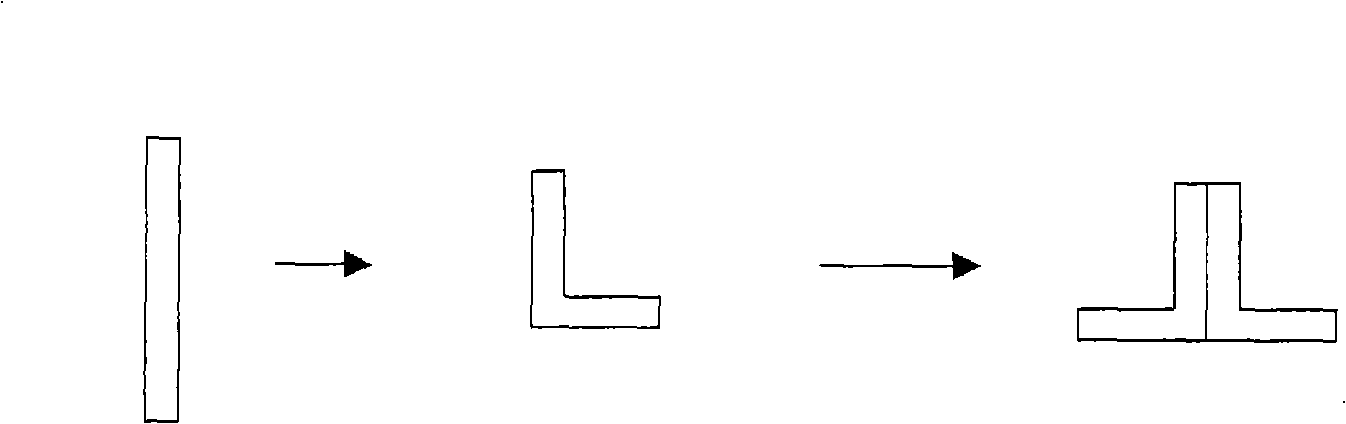

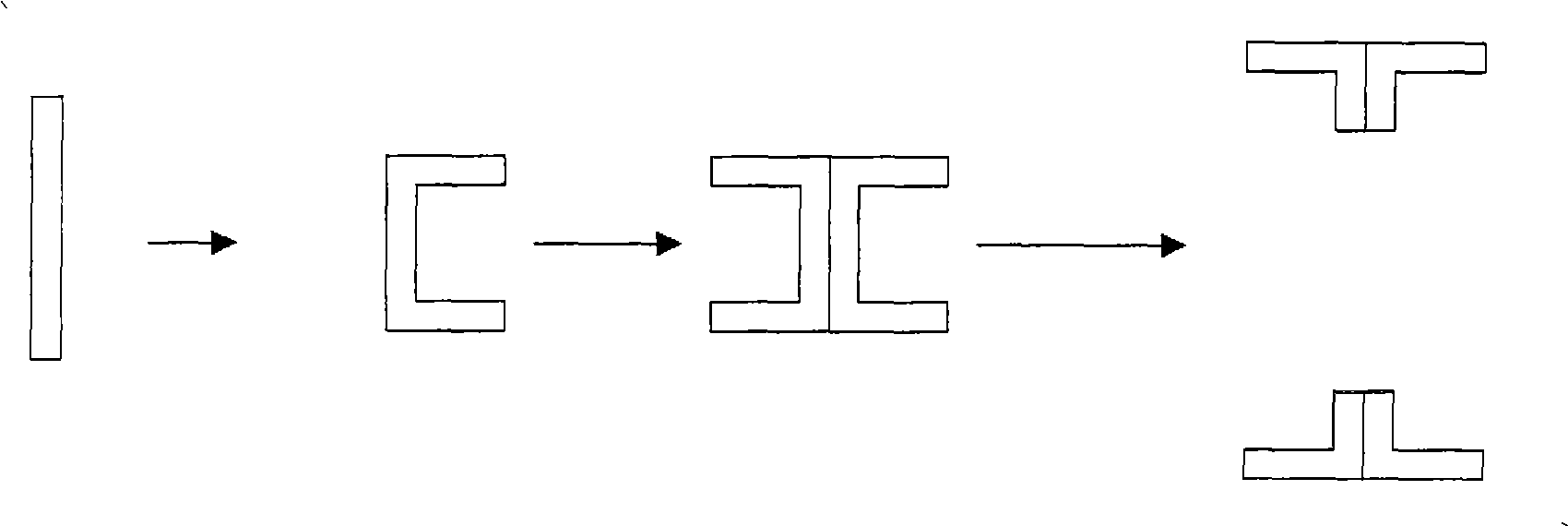

[0032] exist Figure 11 , you can see that the stringer is manufactured in multiple steps.

[0033] In step a) one starts with a planar laminate made of composite material 41 formed from plies of carbon fibers or glass fibers with a thermosetting or thermoplastic resin.

[0034] In step b), said laminate is shaped to define two parts 43 and 45 that will form the foot 15 and two parts 47 and 49 that will form the web 13 . This forming step can be carried out in different ways, for example, using rollers, continuously or semi-continuously by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com