A turbine driven electric power production system and a method for control thereof

A technology of turbines and transmission systems, applied in the control of wind turbines, machines/engines, engines, etc., to achieve the effect of improving accuracy and avoiding instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

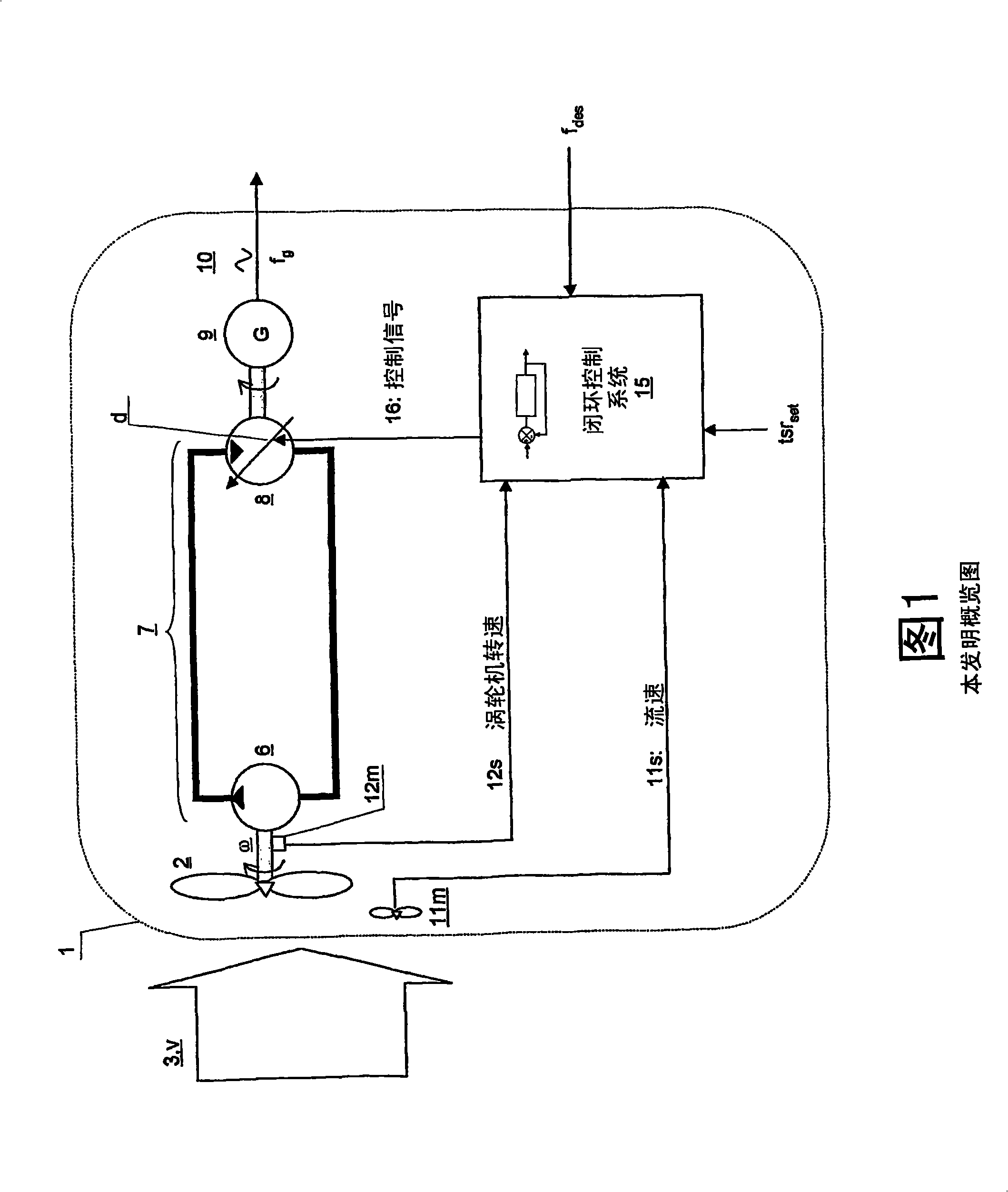

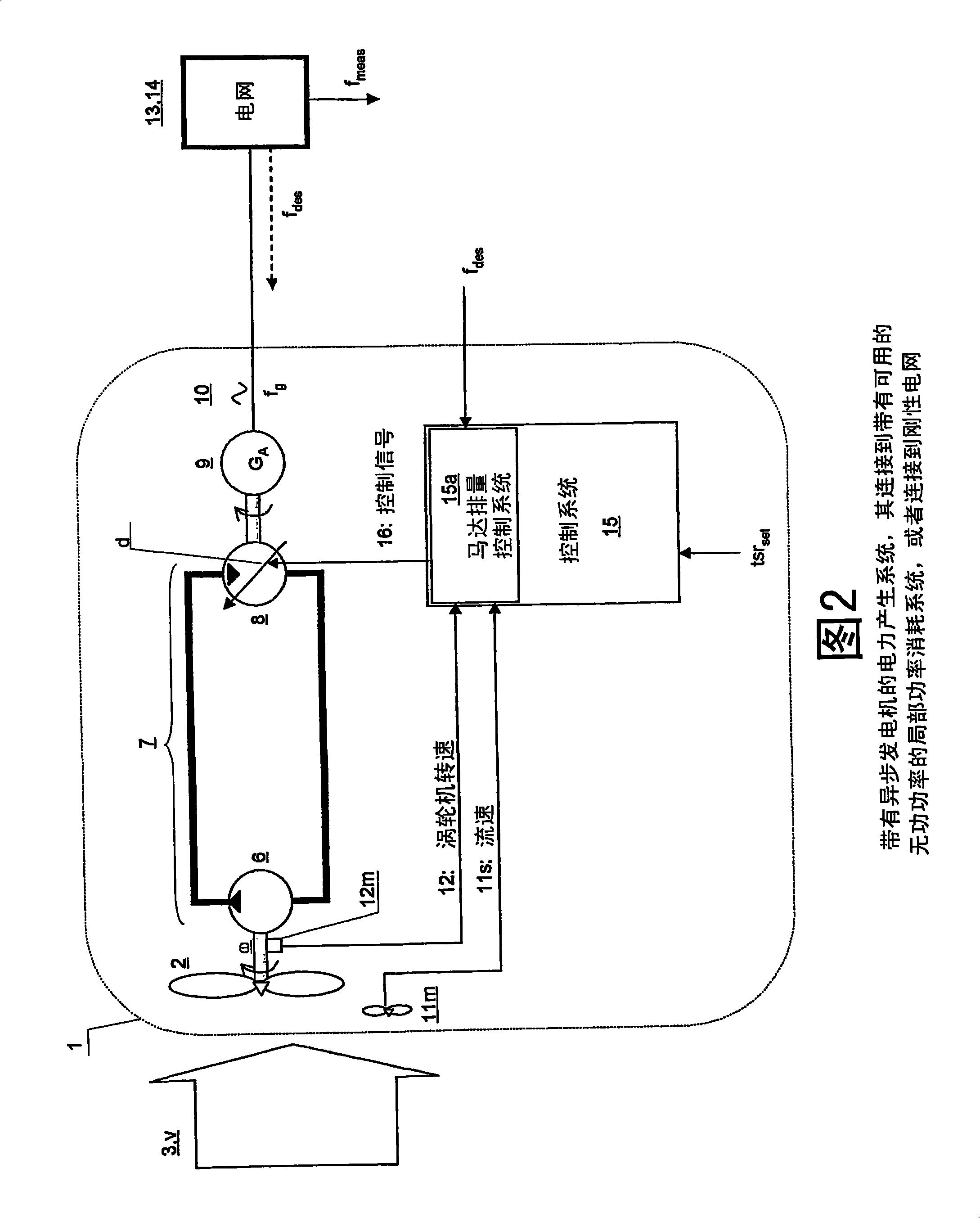

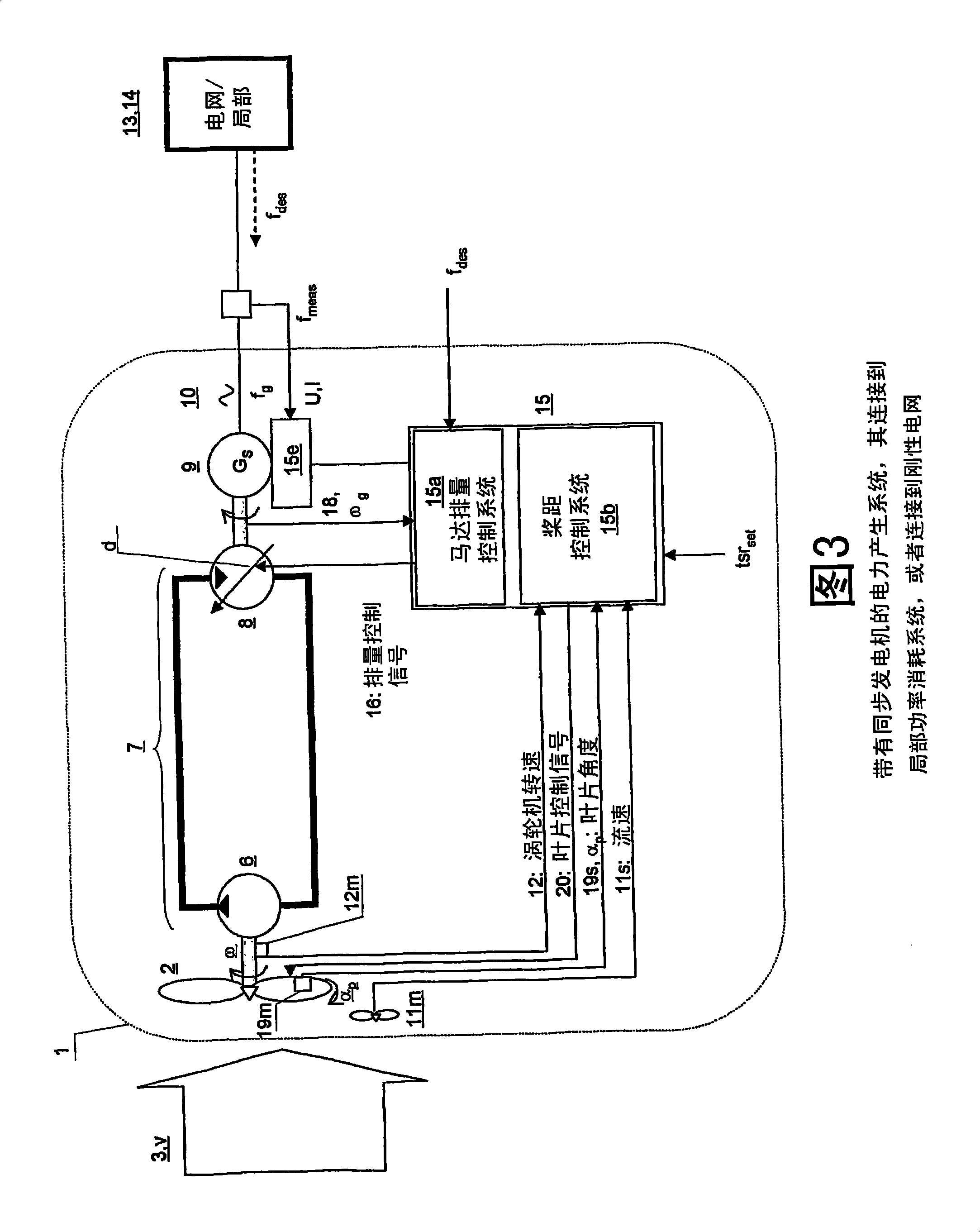

[0051] The invention comprises a turbine driven power generation system (1). The turbine (2) is arranged to be driven by a fluid (3) having a time-varying flow velocity (v), such as is the case with a wind turbine or a water turbine. In the following description, only examples involving wind turbines are discussed, however, it will be apparent to a person skilled in the art that the invention is equally applicable to water driven turbines. Referring to Figure 1, the turbine (2) is connected to operate the hydrostatic displacement pump (6), which is further connected to the hydrostatic displacement motor (8) which is part of the hydrostatic transmission system (7) ). The hydrostatic system may be a closed loop hydrostatic system or an open loop hydrostatic system. The hydrostatic motor (8) is arranged to transmit rotational torque by connecting the hydrostatic motor (8) to a rotating shaft of a generator (9) supplied with alternating current (10). Usually required to stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com