Automotive tire pressure monitoring system calibration instrument and calibration method

A pressure monitoring and system calibration technology, applied in tire measurement, tire parts, vehicle parts, etc., can solve problems such as difficult implementation, error handling and response, and difficulty in low-frequency wake-up coils, achieving low power consumption and simple diagnosis. and calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing, the present invention will be further described:

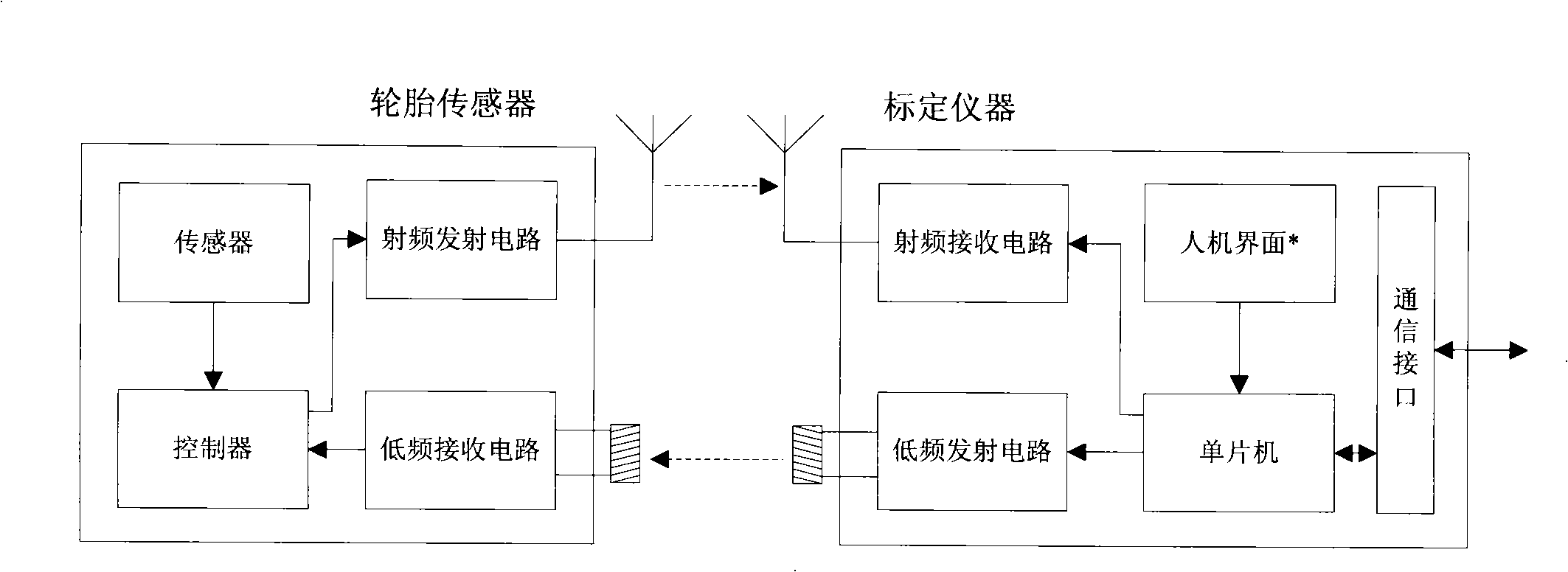

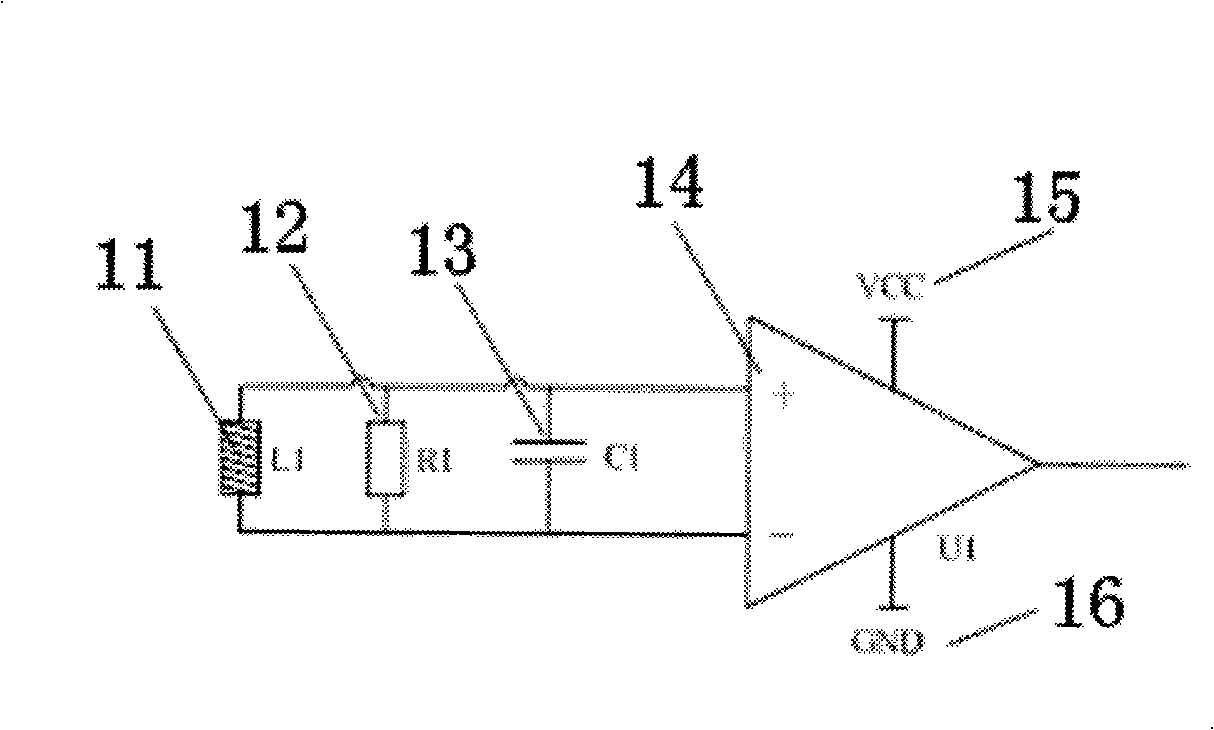

[0046] combine Figure 1-Figure 2 , this embodiment includes two parts, one is a tire pressure sensor; the other is a diagnostic calibration device. Its structure diagram see figure 2 . The tire sensor includes a central control module 2, a sensor 1, a radio frequency transmitting circuit and a low frequency receiving circuit. When the tire sensor receives a diagnostic calibration command through the low-frequency receiving circuit, it sends it to the central control module. The central control module analyzes the command, changes the value of the variable in the internal memory according to the command content, and sends the result through the radio frequency transmitting circuit after the processing is completed. go out. If the diagnosis command is to read the tire parameters, the current tire pressure, temperature, module battery voltage and other values are obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com