Blend biodiesel

A biodiesel and blending technology, used in renewable energy and green fields, can solve the problems of poor low temperature flow performance, easy oxidation and intolerant storage, high raw material cost, and achieve low harm to human body from exhaust gas, low sulfur content, and raw material cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 100 g of cottonseed oil into a three-necked flask equipped with a stirring device, a condensation reflux device and a thermometer, and place it in a constant temperature water bath device with a preset temperature of about 65°C. Take about 1% NaOH of oil weight, dissolve in anhydrous methanol, the molar ratio of anhydrous methanol and cottonseed oil is 6:1. Mix anhydrous methanol in which NaOH is dissolved with coconut oil, and stir for about 2 hours at a rotation speed of about 600r / min. After the reaction is completed, transfer it to a separatory funnel to stand still for more than 8 hours, and the upper layer is the crude biodiesel product. Take the crude biodiesel in the upper layer, and evaporate excess methanol at 80°C. Wash the evaporated biodiesel several times with distilled water until the washing water is clear and transparent. Finally with anhydrous NaSO 4 The excess water is removed, and the biodiesel product is obtained after filtration.

[0040]...

Embodiment 2

[0042] Get 30 parts by volume of coconut oil biodiesel, 15 parts by volume of rapeseed oil biodiesel, 20 parts by volume of cottonseed oil biodiesel, 15 parts by volume of tung oil biodiesel and 20 parts by volume of waste oil biodiesel Mix well in tube 1. This blended biodiesel is denoted B100. Take the mixed biodiesel in test tube 1 and mix them with mineral diesel respectively at mixing ratios of 30%, 20%, 10%, and 0% to form a blended oil. The blended oils are correspondingly expressed as B30, B20, B10, B0.

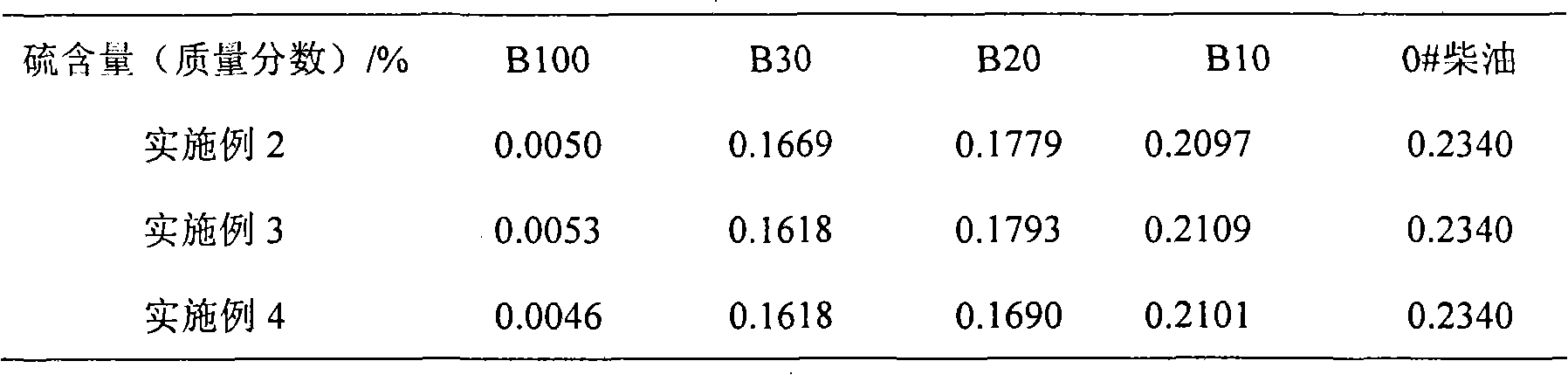

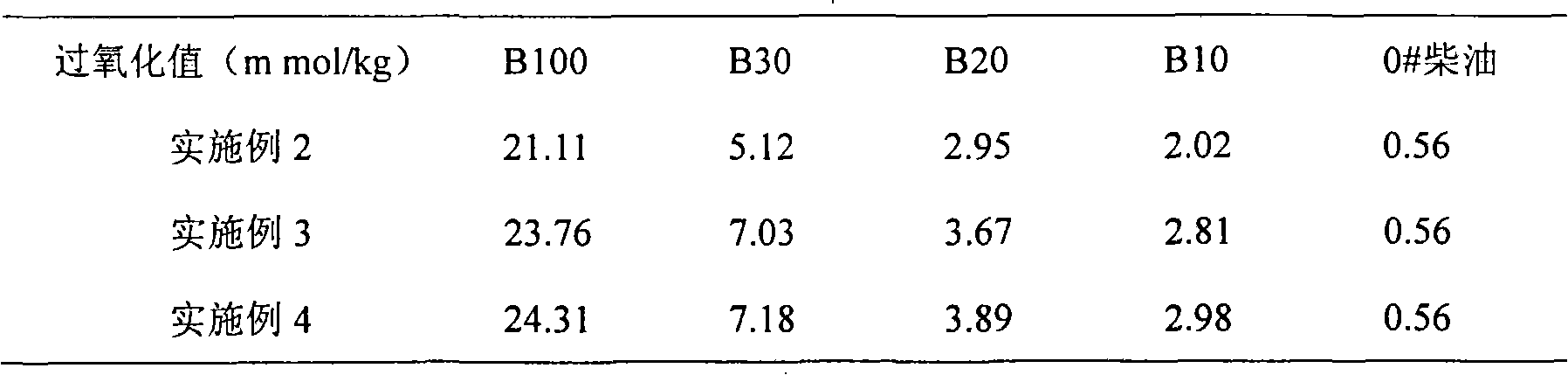

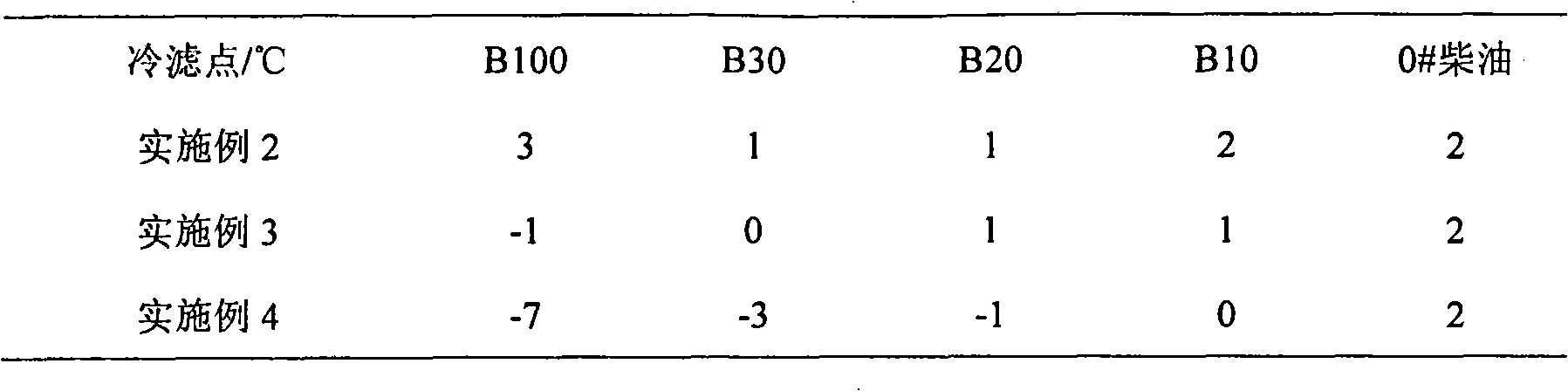

[0043] Follow GB380-77 to measure the sulfur content of blend oil B100, B30, B20, B10 and B0 respectively; follow GBT5538-2005 to measure the peroxide value of blend oil B100, B30, B20, B10 and B0 respectively; follow SH / T0248 to measure the blend Cold filter point for oils B100, B30, B20, B10 and B0. The measurement results of sulfur content, peroxide value and cold filtration point are shown in Table 1-3.

Embodiment 3

[0045] 20 parts by volume of coconut oil biodiesel, 30 parts by volume of cottonseed oil biodiesel, 20 parts by volume of tung oil biodiesel and 30 parts by volume of waste oil biodiesel of Example 1 were placed in test tube 2 and fully mixed. This blended biodiesel is denoted B100. Take the mixed biodiesel in test tube 2 and mix them with mineral diesel respectively at mixing ratios of 30%, 20%, 10%, and 0% to form a blended oil. The blended oils are correspondingly expressed as B30, B20, B10, B0.

[0046] Follow GB380-77 to measure the sulfur content of blend oil B100, B30, B20, B10 and B0 respectively; follow GBT5538-2005 to measure the peroxide value of blend oil B100, B30, B20, B10 and B0 respectively; follow SH / T0248 to measure the blend Cold filter point for oils B100, B30, B20, B10 and B0.

[0047] The measurement results of sulfur content, peroxide value and cold filtration point are shown in Table 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com