Bridge base pillar protecting device

A technology of protection device and barge is applied in the field of protection device for acting force to achieve the effect of reducing the acting force and prolonging the impact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

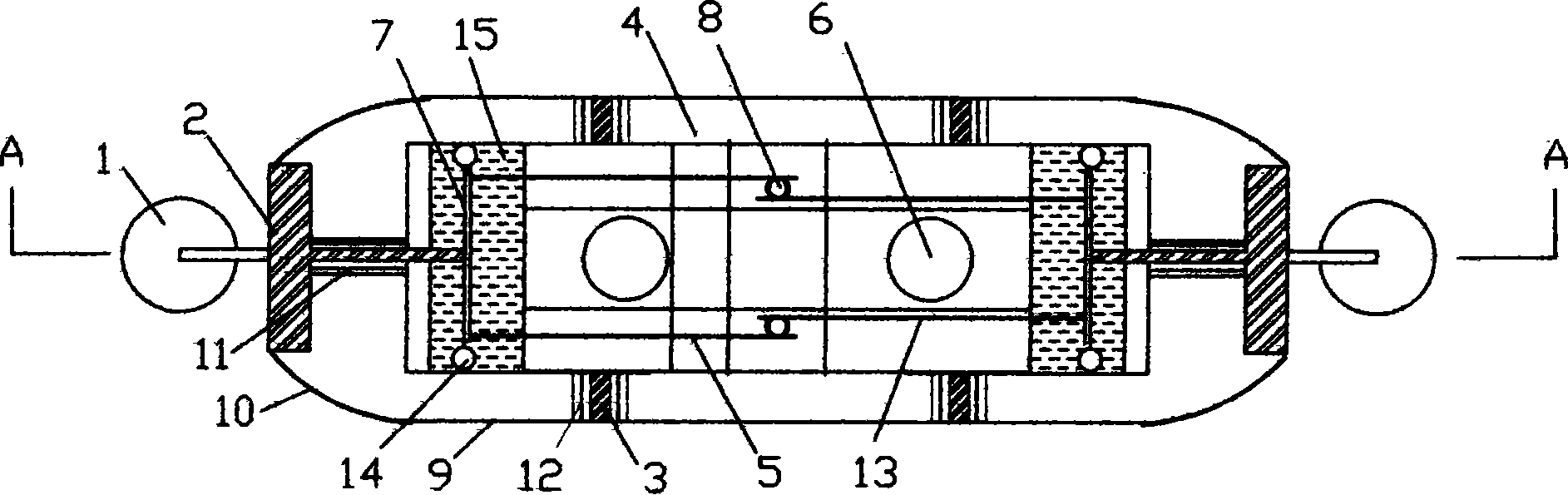

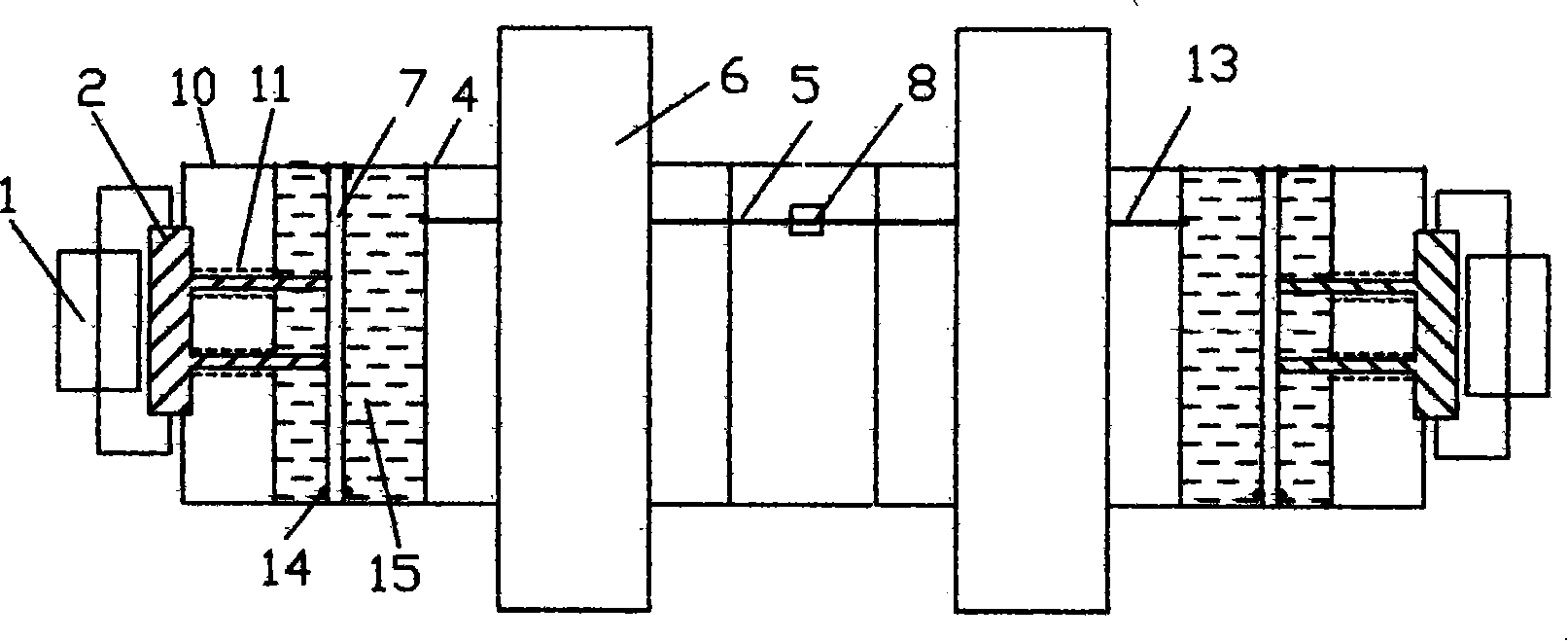

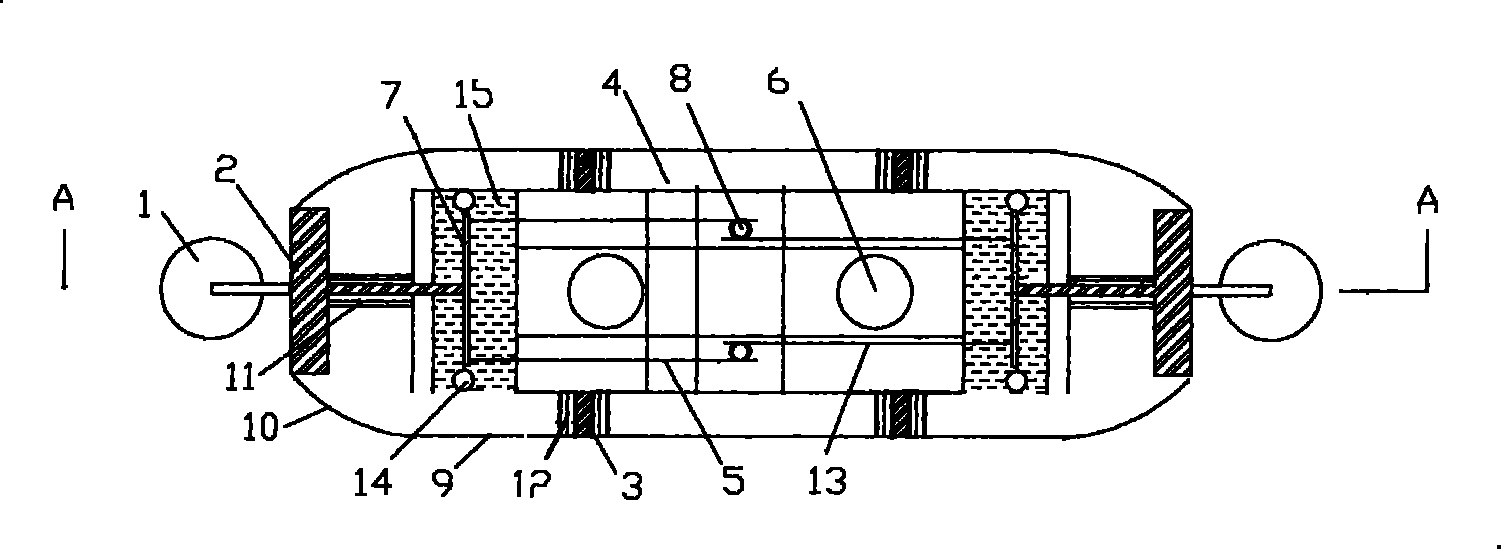

[0025] A bridge column protection device, such as figure 1 , figure 2 As shown, a bridge column protection device, its structural points are: the collision wheel 1 is fixed on the front end of the buffer push rod 2, the side protection plate 9 is connected with the buffer push rod 2 through the flexible joint plate 10, and the other end of the buffer push rod 2 It is connected with the mobile sluice plate 7, and the mobile sluice plate 7 is provided with a pneumatic drive rod 5, the pneumatic drive rod 5 is movably connected with the pneumatic drive rod 13 and the mobile sluice plate on the other side through the reversing wheel 8, and the side protection plate 9 is connected through the Part 3 is connected on the sealed buoyancy tank 4. Sealed pontoon 4 height is 2 meters, floats around bridge pontoon column 6. The buffer push rod 2 is provided with a spring 11 . A spring 12 is arranged on the connecting piece 3 . Guide wheels 14 are installed on the upper and lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com