Complete sealed pump

A fully-sealed, sealing surface technology, used in the field of chemical pumps and sewage pumps, can solve problems such as unreliable sealing, leakage of chemical liquids and sewage, damage to flat sealing rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

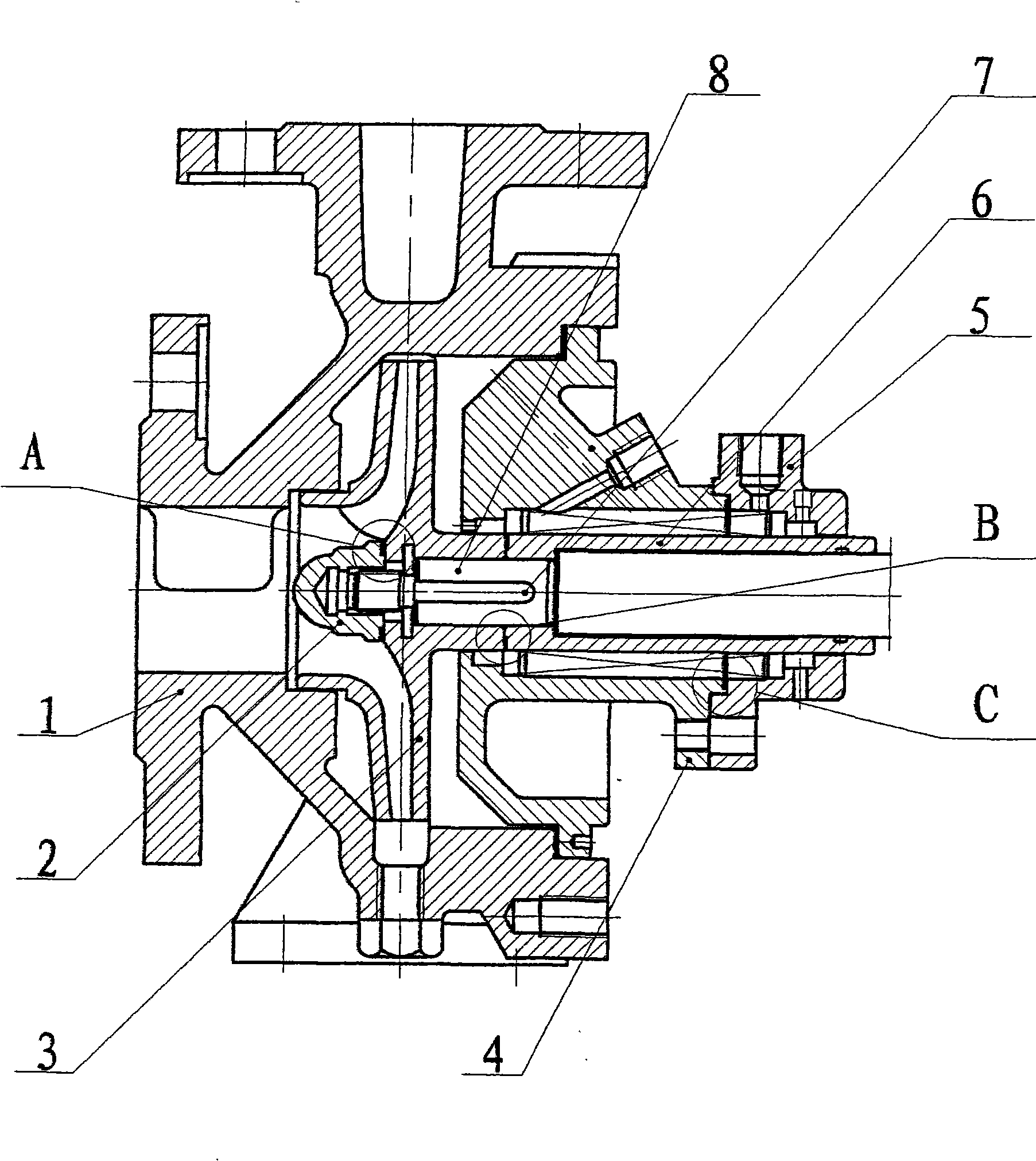

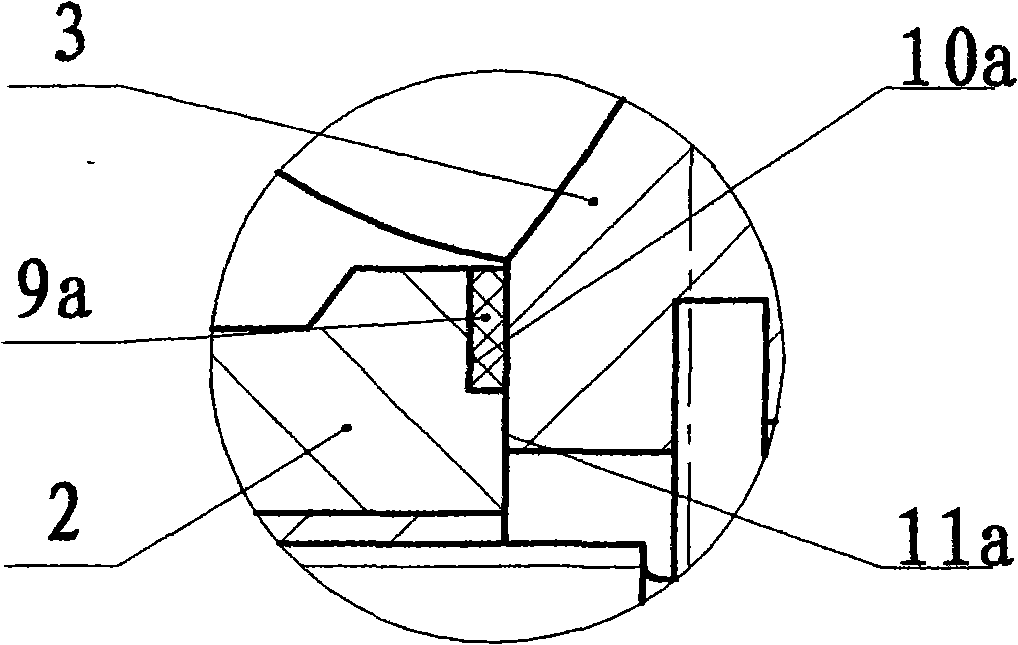

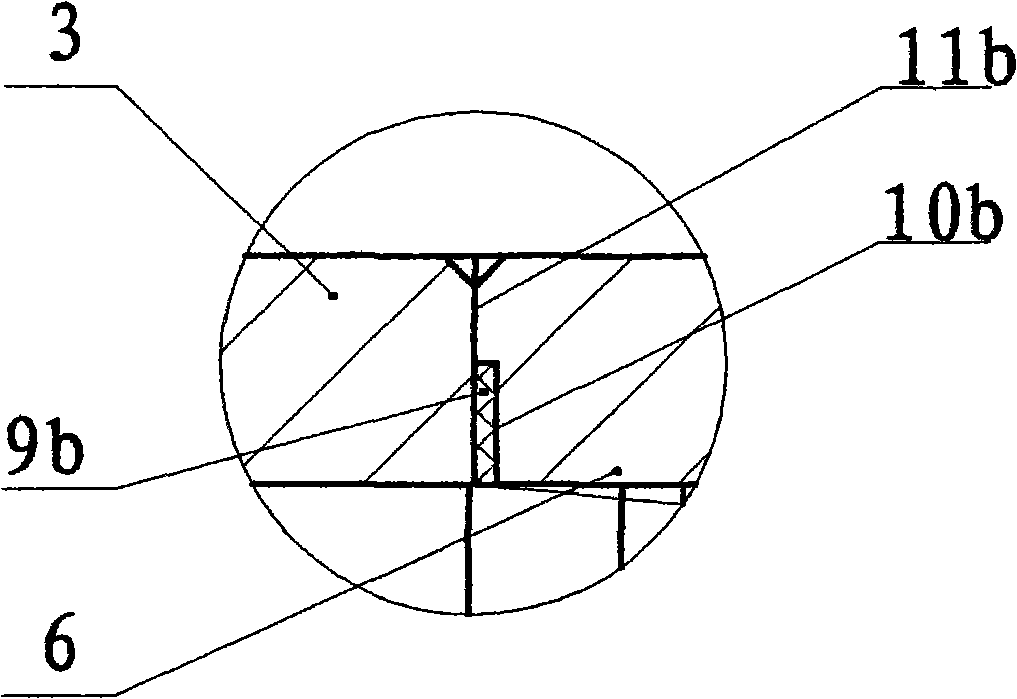

[0015] Such as figure 1 A fully sealed pump is shown, including pump body 1, impeller 3, impeller nut 2, shaft sleeve 6, pump shaft 8, key 7, pump cover 4, gland 5, impeller 3 in pump body 1, shaft sleeve 6. Set it on the pump shaft 8 through the key 7, and lock the impeller and bushing on the pump shaft through the impeller nut 2 at the end of the pump shaft. The pump cover 4 is installed on the pump body 1, and the gland 5 is installed on the pump cover 4. Above, the fastening and sealing surfaces between the impeller 3 and the impeller nut 2, the impeller 3 and the shaft sleeve 6, the pump cover 4 and the gland 5 are all step end surfaces, the convex surface is the stress surface, the concave surface is the sealing surface, and the sealing surface A sealing ring is installed on it. The step end surface is arranged on the fastening sealing surface of the impeller or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com