Vehicle speed change control device

A technology for control devices and vehicles, applied in the direction of engine control, transmission control, components with teeth, etc., can solve the problems of increasing the burden of the synchronization mechanism and prolonging the shifting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

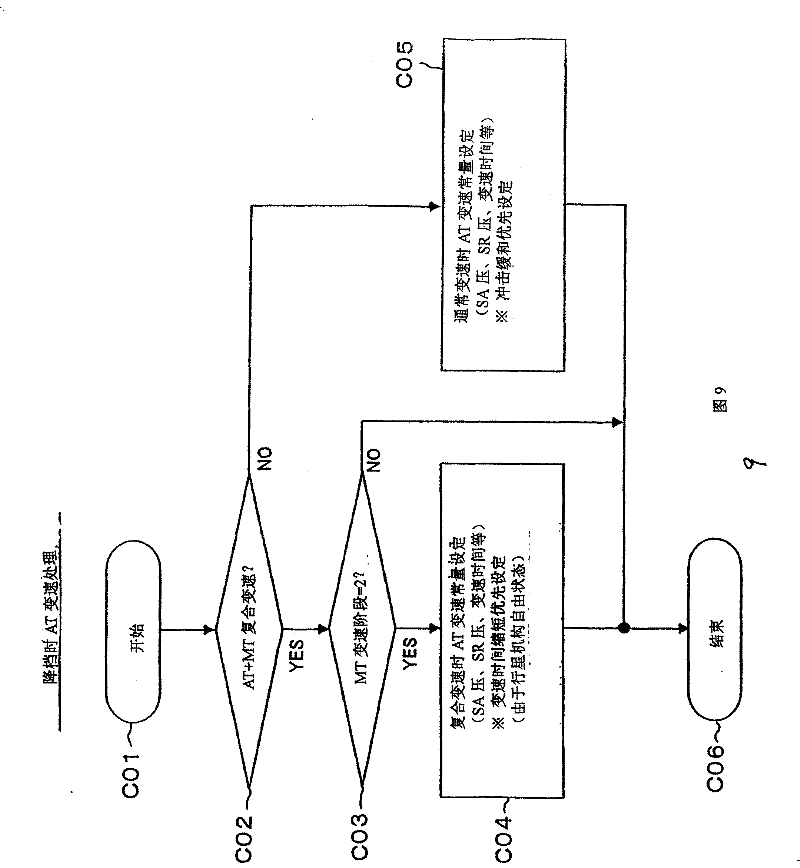

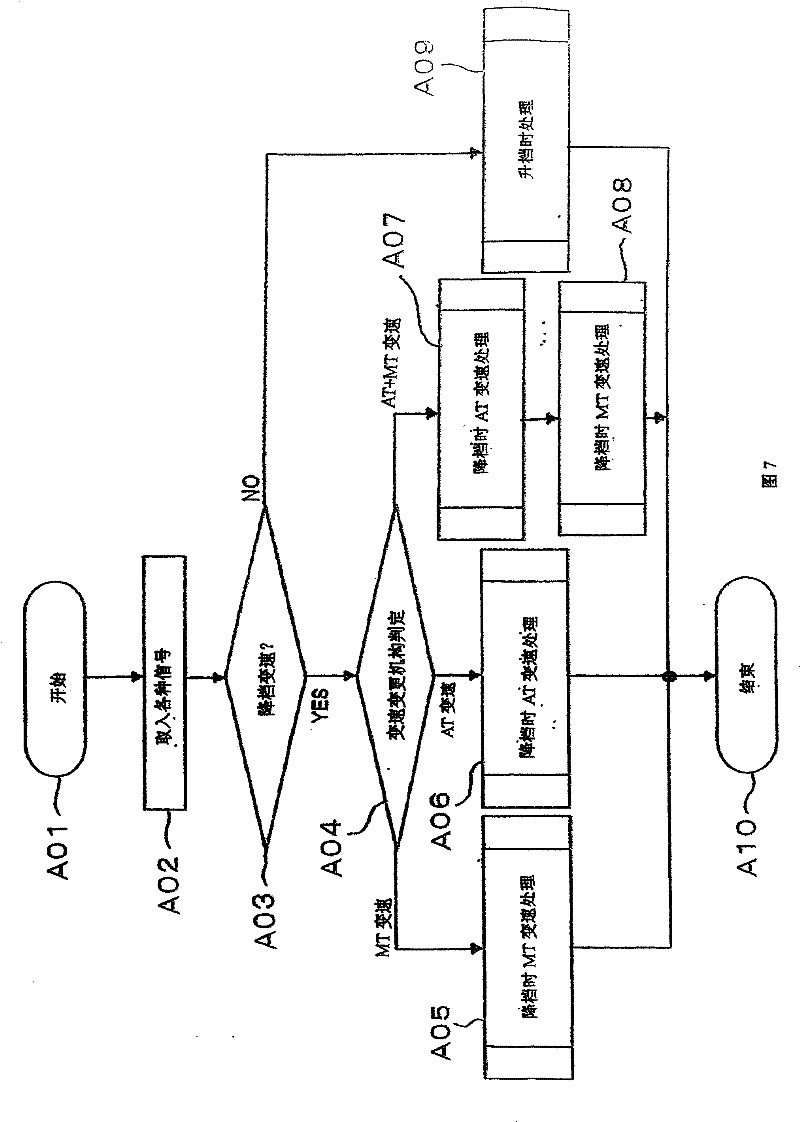

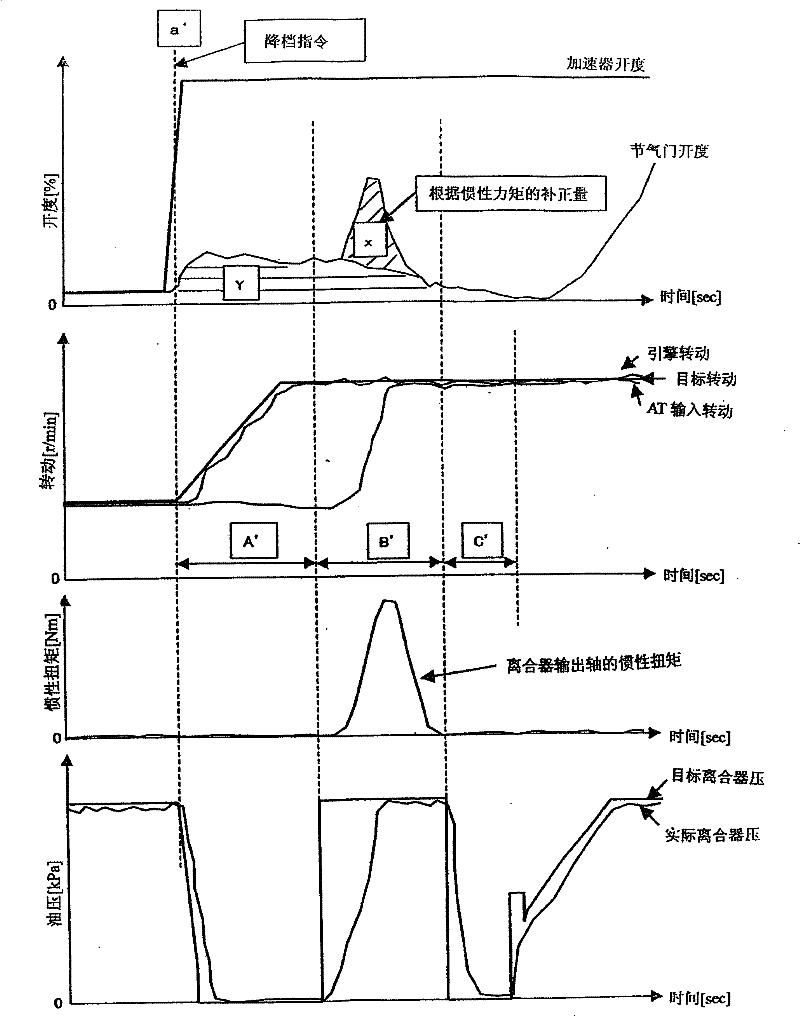

[0045] The embodiments will be described in detail below in conjunction with the accompanying drawings.

[0046] Figure 1-Figure 13 An example of the present invention is shown.

[0047] figure 1 Among them, 1 is the vehicle, and 2 is the power system carried by the vehicle 1. This powertrain 2 includes an internal combustion engine 3 , an automatic transmission (AT+MT) 4 , and a starting clutch 5 as an automatic clutch. Internal combustion engine 3 is connected to automatic transmission 4 via starter clutch 5 .

[0048] The internal combustion engine 3 is provided with: a throttle opening degree control device 7 which is provided with an electronic throttle valve 6 capable of controlling the torque generated by the engine by electronically controlling the degree of opening of the throttle valve; Fuel supply control device 9 for fuel injection valve 8 .

[0049] Automatic transmission 4, the valve body is equipped with a plurality of solenoid valves, and has a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com