Procedure for upshifting gear in a motor vehicle and a power plant unit for a motor vehicle

A technology for shifting high gears in motor vehicles, which is applied in the field of high gear shifting in motor vehicles and power plant units of motor vehicles, which can solve the problems of reduced vehicle comfort, drive train stress, vehicle bumps, etc., and achieve the effect of eliminating reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

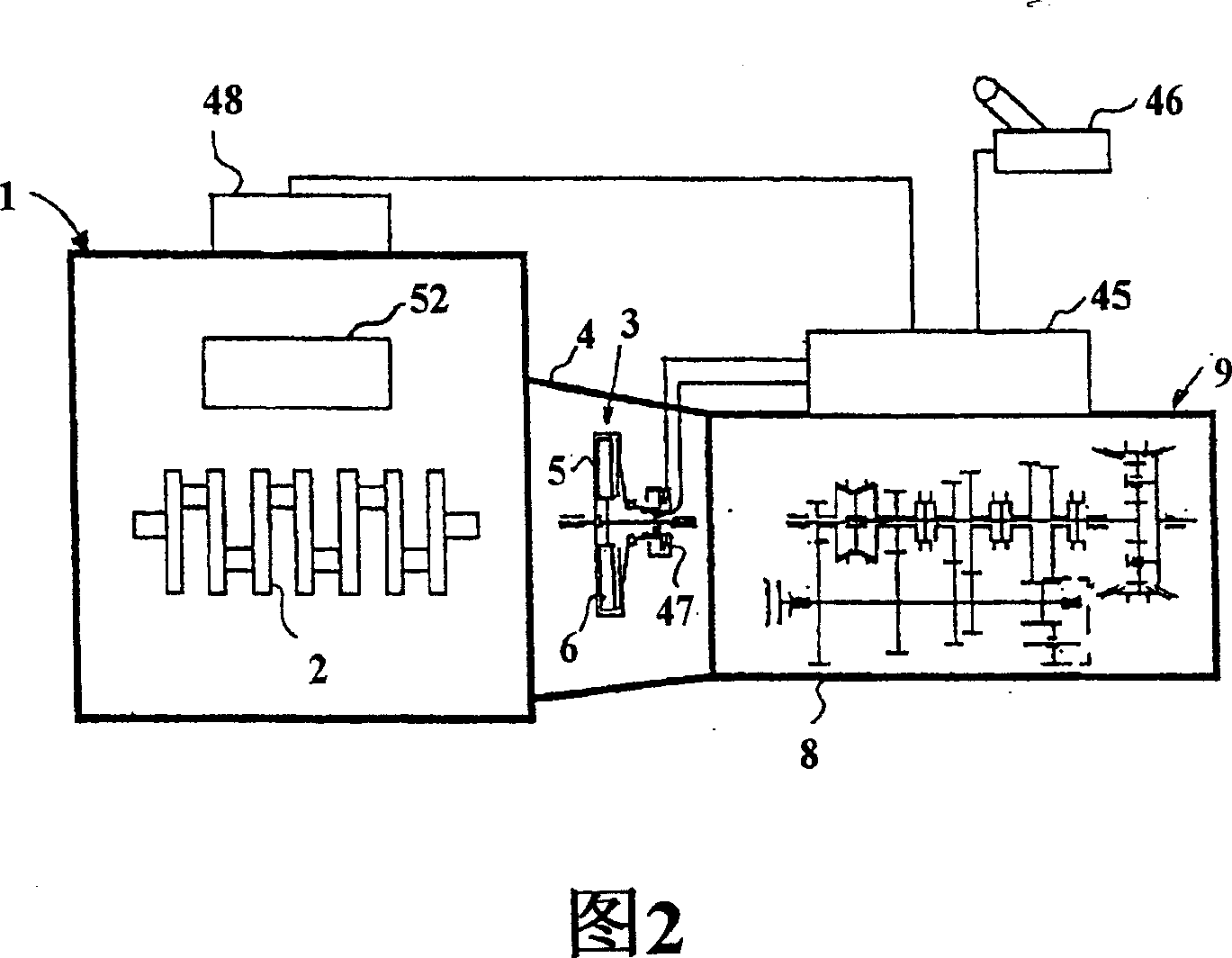

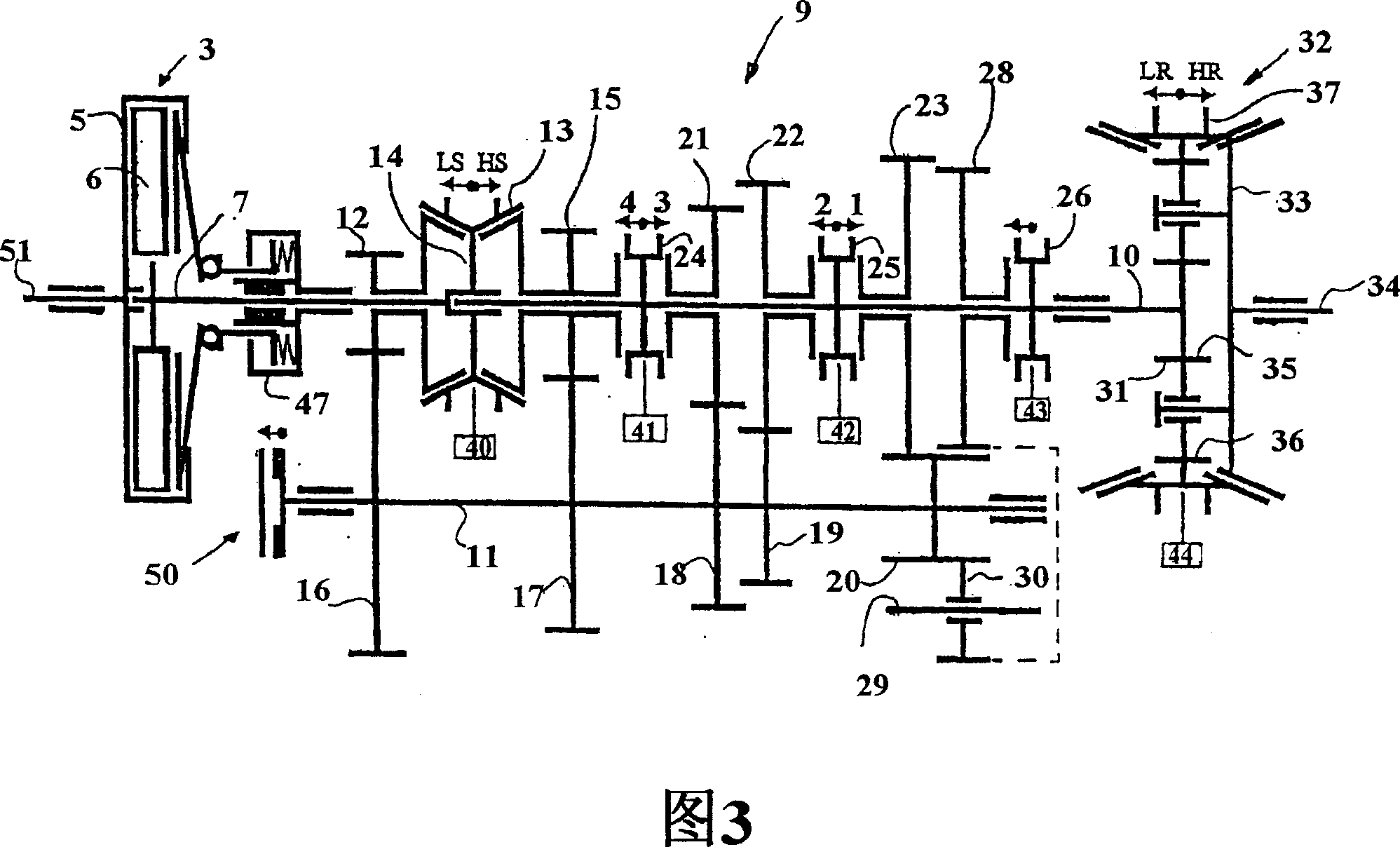

[0028] In FIG. 2, reference numeral 1 designates a six-cylinder internal combustion engine, such as a diesel engine, whose crankshaft 2 is connected to a single-plate dry disc clutch, designated by reference numeral 3, which is housed in a clutch housing 4 . The double disc type can be used instead of the single disc clutch. Through the output shaft 51 of the engine (see Figure 3), the crankshaft 2 is non-rotatably connected to the clutch housing 5 of the clutch 3, while its disc 6 is non-rotatably connected to the input shaft 7, which is rotatably is installed in the housing 8 of the gearbox, generally indicated by reference number 9 . Main shaft 10 and intermediate shaft 11 are also rotatably mounted within housing 8 . It should also be noted that the engine control unit 48 , the transmission control unit 45 and the manual gear selector 46 connected to the transmission control unit 45 . The transmission control unit 45 and the engine control unit 48 are adapted to communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com