Two-gear automatic transmission assembly

A technology of automatic transmission and assembly, applied in the field of vehicle transmission system, can solve the problem of long neutral position positioning time, etc., and achieve the effect of shortening the shifting time, short shifting time, and reducing the time of power interruption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

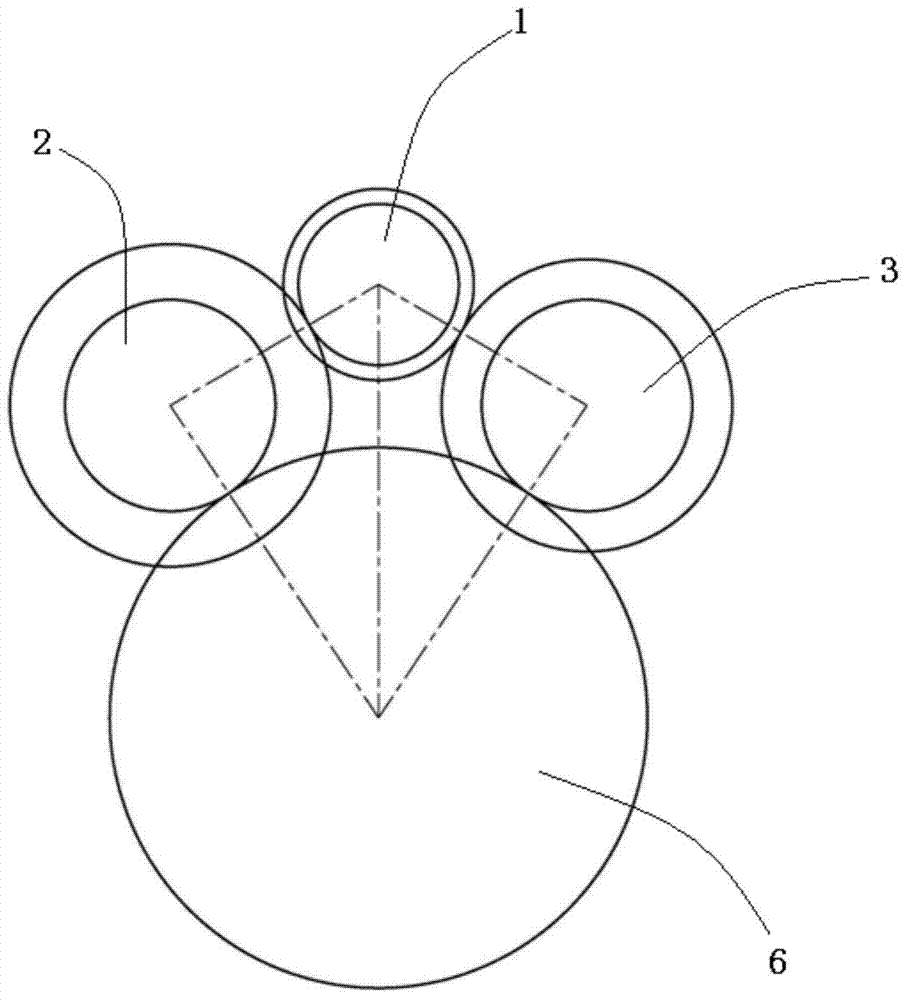

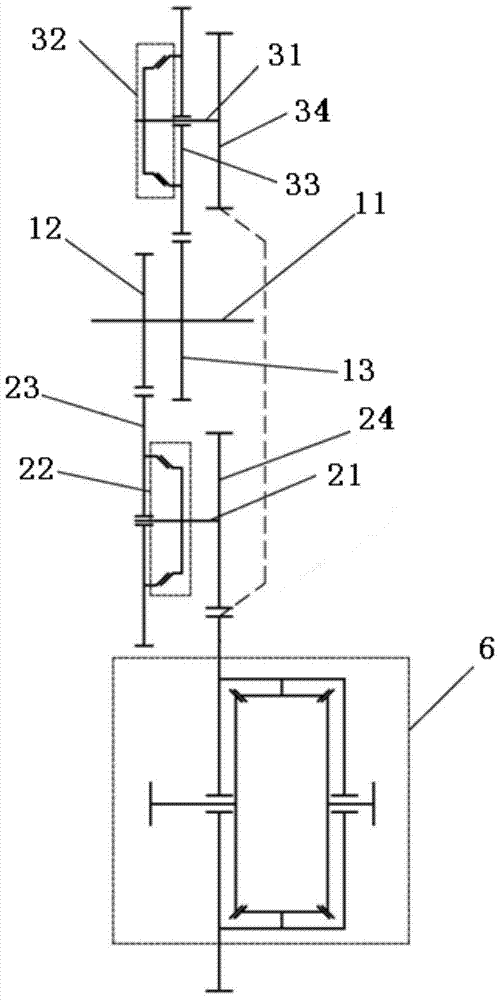

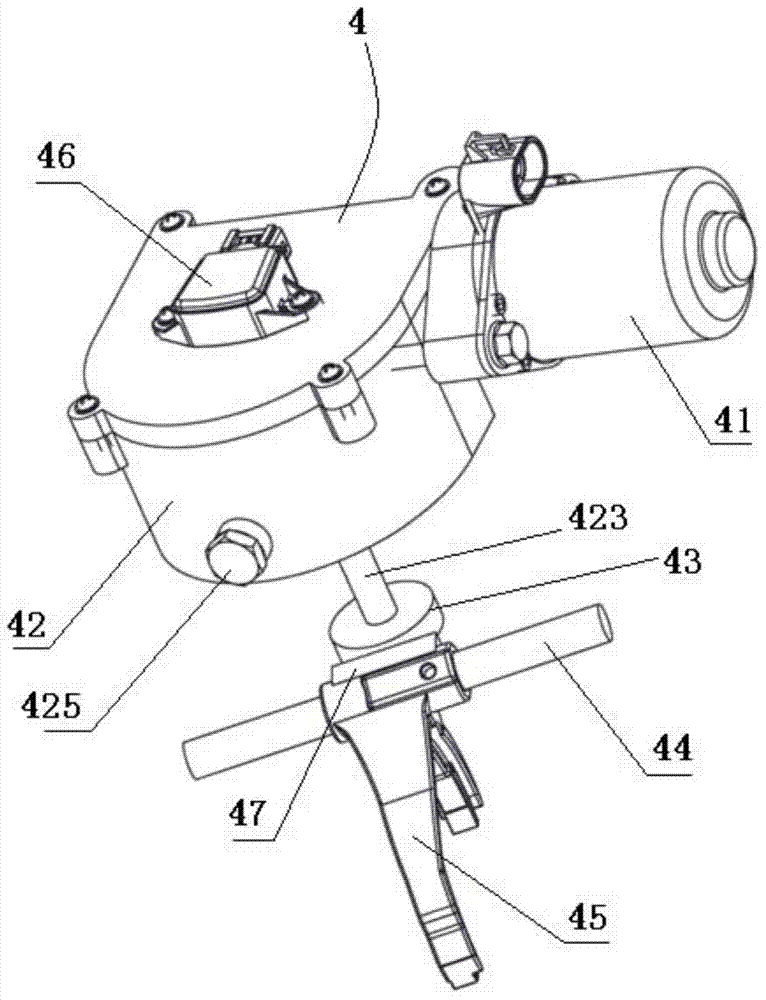

[0043] Such as figure 1 and figure 2 As shown, a two-speed automatic transmission assembly includes an input shaft assembly 1, a first intermediate shaft assembly 2, a second intermediate shaft assembly 3, a first intermediate shaft shift actuator 4, a second intermediate shaft shift Gear actuator and differential assembly 6, the input shaft assembly 1 is transmitted to the first countershaft assembly 2 and the second countershaft assembly 3 through gear meshing, the first countershaft assembly 2 and the second intermediate shaft assembly 3 are respectively engaged and transmitted to the differential assembly 6 through gears, and the differential assembly 6 outputs power to the external left and right drive wheels; the first The intermediate shaft shift actuator 4 drives the first intermediate shaft assembly 2 to work in the first gear state or the neutral state under the control of the external transmission controller, and the second intermediate shaft shift actuator is con...

Embodiment 2

[0069] refer to Figure 6 and Figure 7 , this embodiment 2 includes all the technical features of embodiment 1, and the difference is that when the life of the driving gear 12 of the first gear can meet the requirements of all working conditions, the driving gear 12 of the first gear and the driving gear 13 of the second gear can be combined, At this time, the cost of one gear can be reduced, further reducing the manufacturing cost of the transmission.

[0070] To sum up, the present invention proposes a two-speed automatic transmission assembly, which adopts a double countershaft transmission structure, wherein the two gears are arranged on different countershafts, and are driven by two independent shift actuators. , each synchronizer has only two positions, which are the in-gear position and the neutral position respectively. Therefore, during the de-gearing process of the two-speed automatic transmission assembly of the present invention, the executive motor is always dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com