High-fiber soybean products and process for the preparation thereof

A soybean and soybean milk technology, applied in food preparation, dairy products, milk substitutes, etc., can solve the problems of difficult micronization of soybean powder, poor taste, rough texture of soybean food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] 6) Preparation of soybean food

[0041] As explained further below, various types of soybean foods such as soybean milk, tofu, etc., which contain all the nutritional components of whole soybeans, can be manufactured by using the whole soybean milk prepared above.

[0042] 6-1) Whole soybean milk products

[0043] The whole soymilk prepared in 5) is processed into a packaged soymilk product through a traditional post-processing method. Food additives such as additives for adjusting the viscosity of soymilk, and flavored concentrated water extract or juice may be added to the whole soymilk. When packing the soymilk into a paper package, the soymilk is sterilized at 150° C. for 3 seconds and then packaged so that the soymilk product can be circulated at room temperature. If bottled, pour soymilk into the bottle and sterilize at 121°C for 5-20 minutes. The whole soymilk product comprises soybean particles preferably having an average particle diameter of 50 μm or less a...

Embodiment 1

[0056] Example 1: Preparation of whole soybean milk from germinated soybeans 1

[0057] (Step 1) Preparation of Germinated Soybeans

[0058] 300 kg of unhulled soybean grains were selected, washed with water, and soaked in 1,200 liters (1) of water at 20° C. for 10 hours.

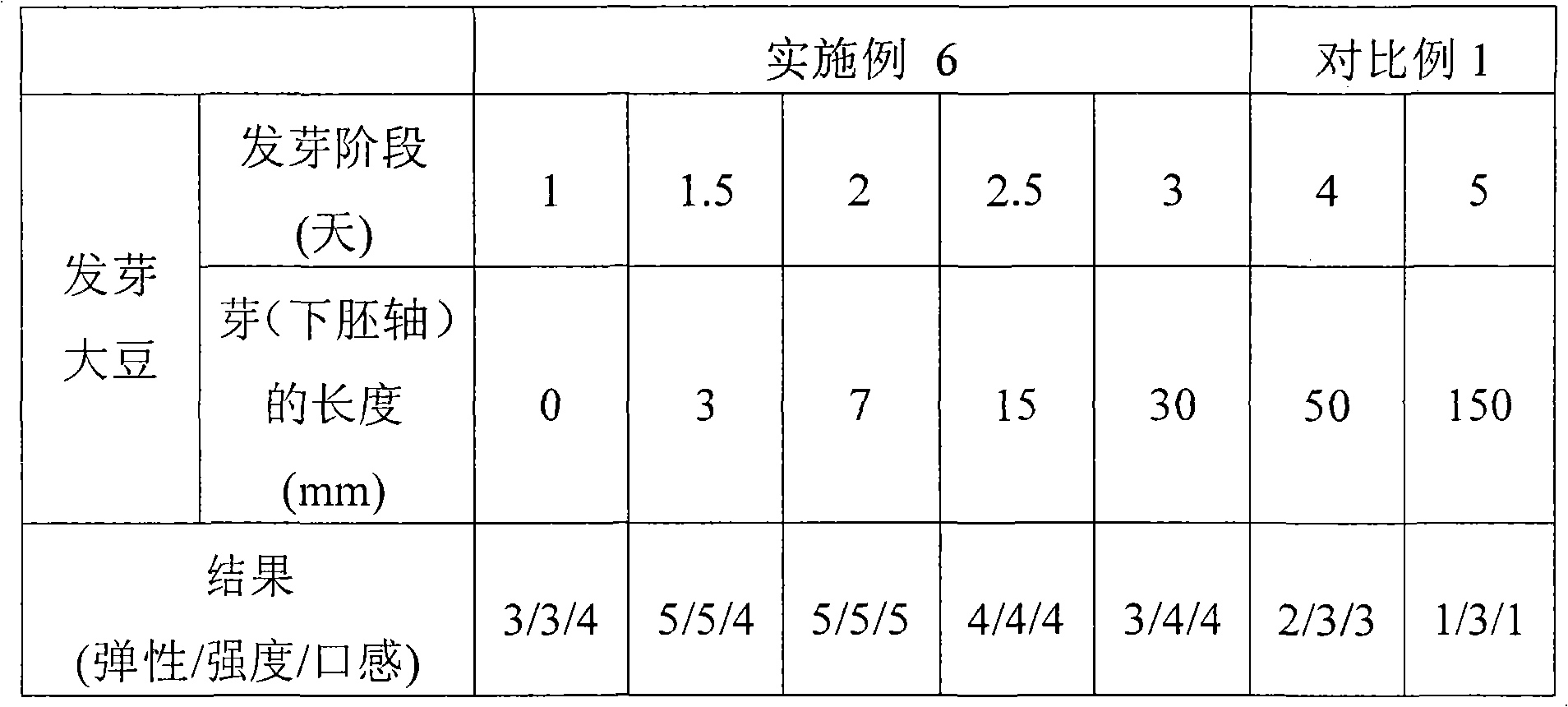

[0059] Discard the soaking water, put the soaked soybeans into a germination box with a thickness of 20-30mm, then cover the lid to keep the surface moist, and germinate at a temperature of 20-25°C for 0, 5, 10, 15 and 20 hours respectively. In order to promote germination, the soybeans are fully watered with water at a temperature of 18-30°C at intervals of 2-3 hours.

[0060] When germination is complete, the soybeans are washed with water and used in subsequent processes.

[0061] (Step 2) Preparation of whole soybean milk from germinated soybeans

[0062] 650 kg of germinated soybeans obtained in Step 1 were transferred to a crusher (Seiken, Japan) and stirred to grind them while adding 1,500 liters ...

Embodiment 2

[0064] Example 2: Preparation of whole soymilk from germinated soybeans 2

[0065] 650 kg of germinated soybeans obtained in Step 1 were transferred to a crusher (Seiken, Japan) and stirred to grind them while adding 1,500 liters of distilled water. The resulting soybean slurry was heated at 105°C for 3 minutes to inactivate the enzyme and passed through a decanter to separate solid matter and soymilk. Add 50 g of enzyme mixture (cellulase: pectinase = 2:1) (cellulase: Amano, Japan; pectinase, Sungwoo, Korea) to the solid matter, in a rotary micronizer maintained at 60°C The resulting mixture was subjected to continuous rotary micronization and enzymatic degradation micronization in a (Hansung mill, Korea).

[0066] The micronized soymilk was uniformly micronized by applying a pressure of 500 bar with a high-pressure homogenizer (Donga Homogenizer, China), and combined with the above-separated soymilk to obtain fully germinated soymilk (approximately 13 brix %).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com