Optimized armature assembly guidance for solenoid valves

A technology of guiding device and solenoid valve, which is applied in the direction of fuel injection device, special fuel injection device, charging system, etc. It can solve the problems of affecting the injection volume, increasing friction force, collision between the armature plate and the magnet armature, etc., and achieves the improvement of portability sex, effortless movement, and ease-oriented effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

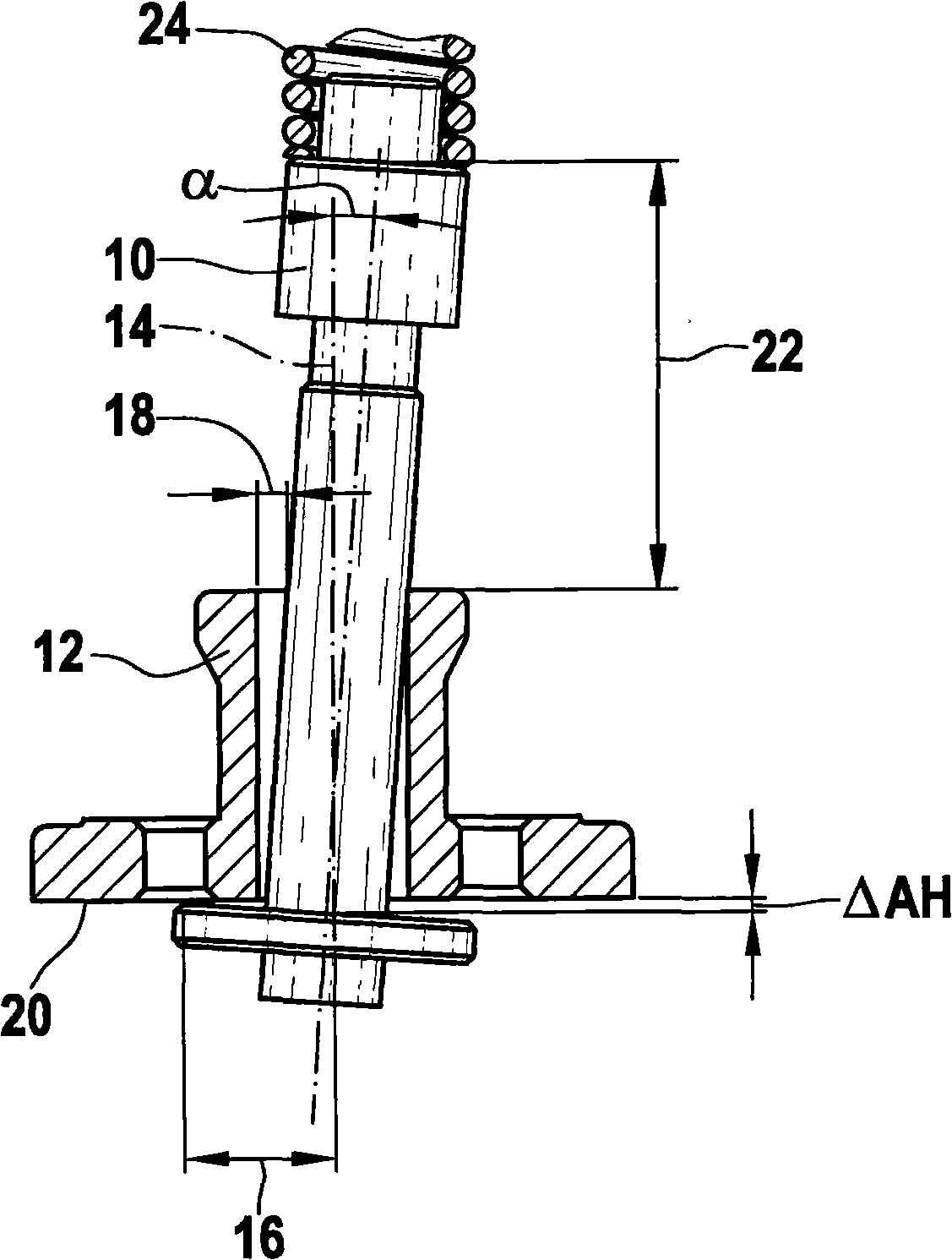

[0017] From figure 1 The influence of the guide play between the armature pin shown in enlarged view and the armature guide according to the prior art can be seen in the description of , the armature plate of which is not shown.

[0018] figure 1 An armature pin 10 is shown, which is surrounded by an armature guide 12 . The armature pin 10 is loaded by a valve spring 24 . A distance 22 exists between the upper annular surface of the armature guide 12 and the force introduction point of the valve spring 24 . The transverse forces occurring between the armature pin 10 and the armature guide 12 decrease as the distance 22 decreases. follow in figure 1 In the arrangement shown in , there is a guide gap 18 between the outer surface of the armature pin 10 and the inner surface of the armature guide 12 . exist figure 1 The armature pin 10 is shown in the described tilted state relative to the main injector axis 14 with the tilt angle α. exist figure 1 The tipping shown on an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com