Antismudge, water repellent, and antistatic pressure-sensitive or adhesive tape for protection

A technology of conductive polymers and tapes, applied in the field of cloth or tape, pressure sensitive or adhesive film, can solve the problems of complex manufacturing process, increased scratches, high product price, etc., and achieve good antistatic performance , prevent the adhesion of impurities, and achieve the effect of water repellency and antifouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] The present invention can be better understood by the following examples, which are provided for illustration and should not be construed as limiting the invention.

[0068]

[0069] Measurement of electrostatic voltage at peeling: Measured using a 718A static sensor available from 3M when an adhesive-coated protective tape is attached to the surface of a polarizing film for LCD and then peeled off at a rate of 300mm / minute The electrostatic voltage generated at this time.

[0070] Measurement of Surface Resistance and Decay Time: The surface resistance of the outermost layer of the protective tape and its adhesive-coated surface was measured using SRM110. In addition, the upper and lower parts of the film were connected to each other using a ground clamp, and then the decay time required for the voltage to drop from an initial applied amount of 1000 V to 100 V was measured using a Monroe CPM 288.

[0071] Measurement of contact angle: 10 points on a surface with a s...

Embodiment 1

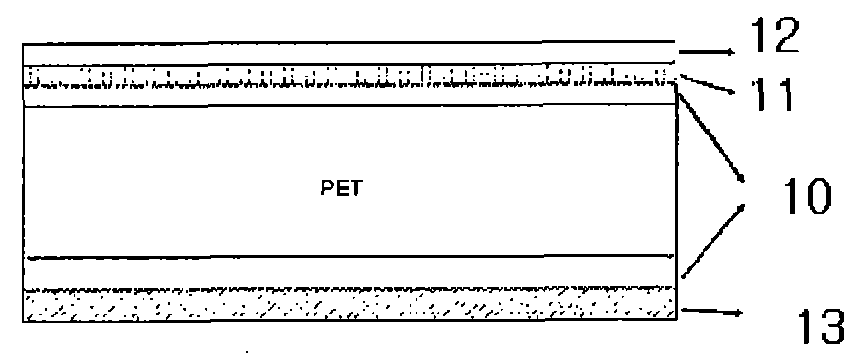

[0093] A thermosetting antistatic solution with waterproof effect and antifouling effect was prepared, coated on one surface of a 36 m thick PET film to a thickness of 0.1 μm, and then dried at 80° C. for 2 minutes. Also, on the other surface of the film, an acrylic adhesive was coated to a thickness of 15 μm.

[0094] The surface resistance of the film was determined to be 10 7 Ω / μm. The film was cut into a size of 25 mm×100 mm, attached to the polarizing film, and then peeled off at a rate of 300 mm / minute. As a result, the electrostatic voltage generated was 100V, and the decay time after application of 1000V was 1.8 seconds, so fast decay was not achieved.

[0095] The contact angle was measured to be about 92 using a surface tensiometer. When the film was pressed with a finger, no fingerprints were observed on the surface.

[0096] Therefore, the thus-produced thin film is advantageous because it has excellent properties and the manufacturing process is simplified by ...

Embodiment 2

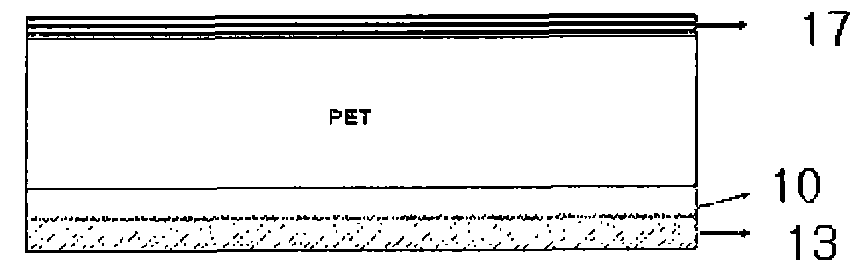

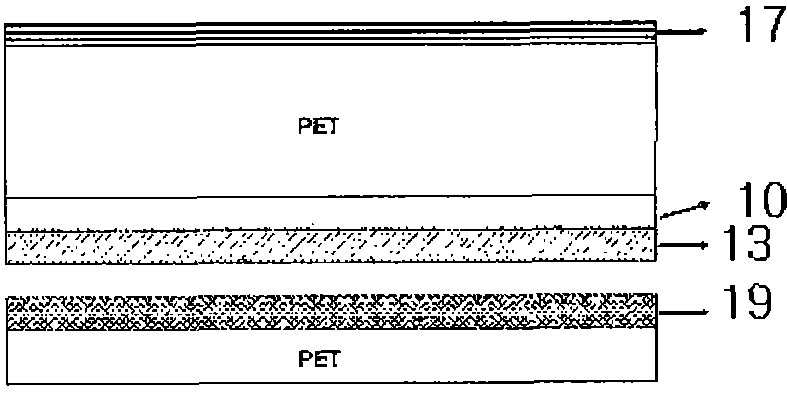

[0098] A UV curable antistatic solution with waterproof and antifouling effects was prepared, coated on one surface of a 36 μm thick PET film to a thickness of 0.1 μm, dried at 60° C. for 2 minutes, and then cured with 800 mJ of light. Also, on the other surface of the film, an acrylic adhesive was coated to a thickness of 15 μm.

[0099] The surface resistance of the film was determined to be 10 7 Ω / μm. The film was cut into a size of 25 mm×100 mm, attached to the polarizing film, and then peeled off at a rate of 300 mm / minute. As a result, the electrostatic voltage generated was 100V, and the decay time after application of 1000V was 1.8 seconds, so fast decay was not achieved.

[0100] The contact angle was measured to be about 93 using a surface tensiometer. When the film was pressed with a finger, no fingerprints were observed on the surface.

[0101] The hardness of the surface treated with antistatic treatment and waterproof and antifouling treatment was observed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com