Safe type inverse direct-current welding machine

A safe, direct current technology, applied to arc welding equipment, welding equipment, manufacturing tools, etc., to achieve clear instructions, convenient switching, and prevent electric shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

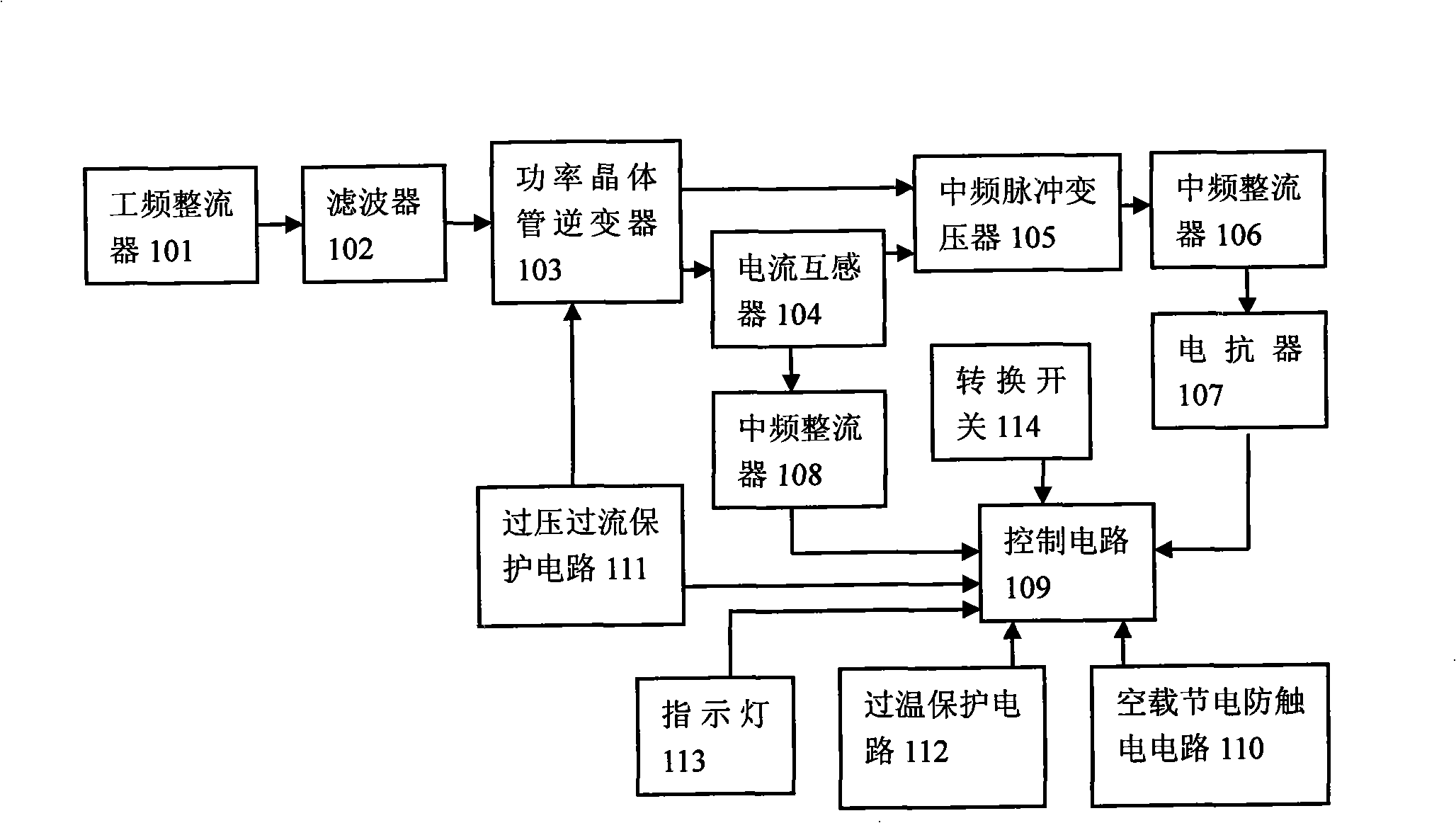

[0028] like figure 1 As shown, the present invention provides a safe inverter DC welding machine, including:

[0029] Power frequency rectifier 101;

[0030] A filter 102, the input end of which is connected to the output end of the power frequency rectifier 101;

[0031] A power transistor inverter 103, the input end of which is connected to the output end of the filter 102;

[0032] A current transformer 104, the input end of which is connected to the output end of the power transistor inverter 103;

[0033] An intermediate frequency pulse transformer 105, whose input ends are respectively connected to the output ends of the power transistor inverter 103 and the current transformer 104;

[0034] Intermediate frequency rectifier 106, its input end is connected to the output end of intermediate frequency pulse transformer 105;

[0035] A reactor 107, the input end of which is connected to the output end of the intermediate frequency rectifier 106;

[0036] An intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com