Large-sized aqueduct prestressing force construction method

A construction method and prestressing technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of difficult construction, self-heavy single-span troughs, and the inability of a single trough to meet the requirements of a large amount of water delivery, so as to shorten the construction period. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

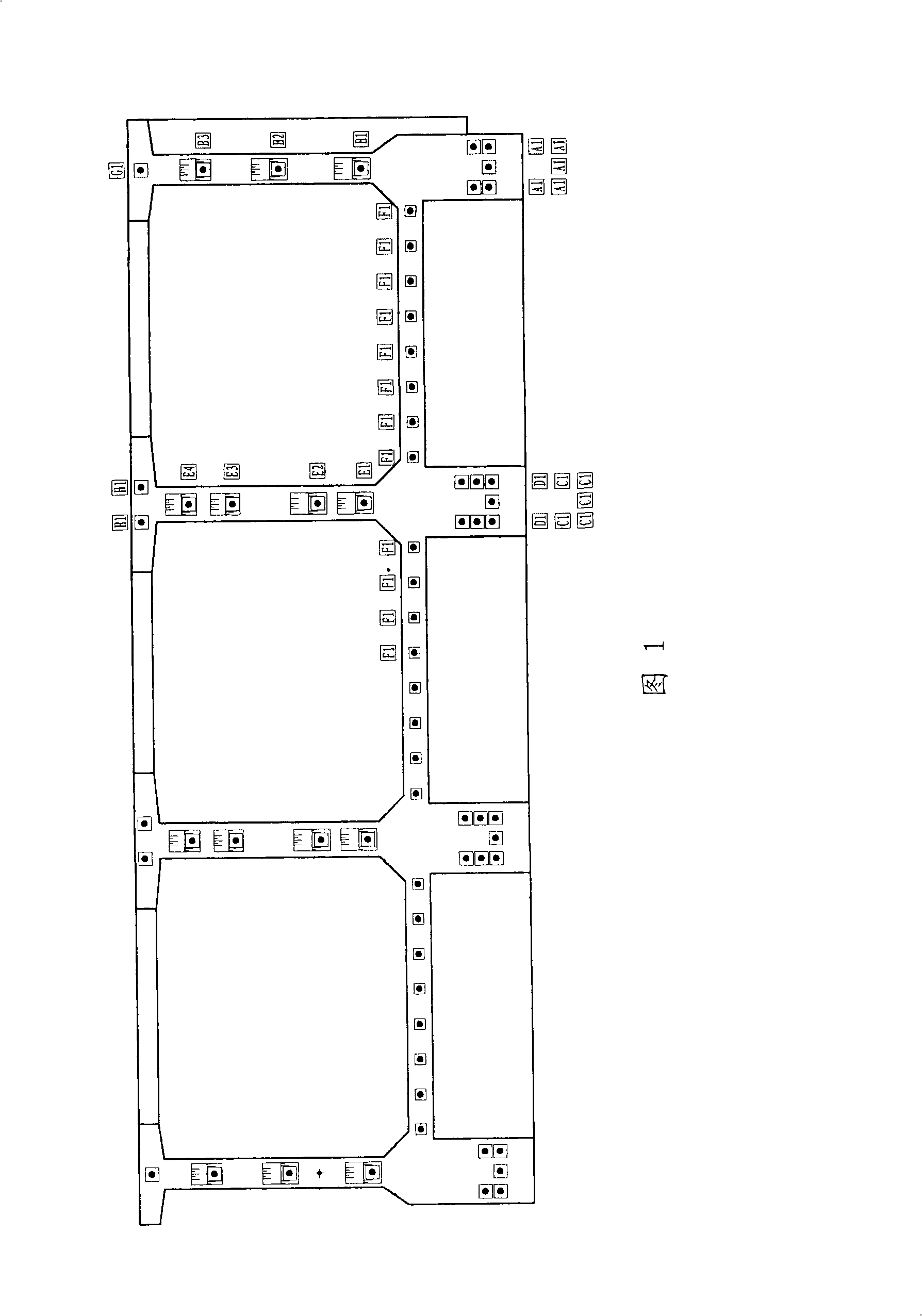

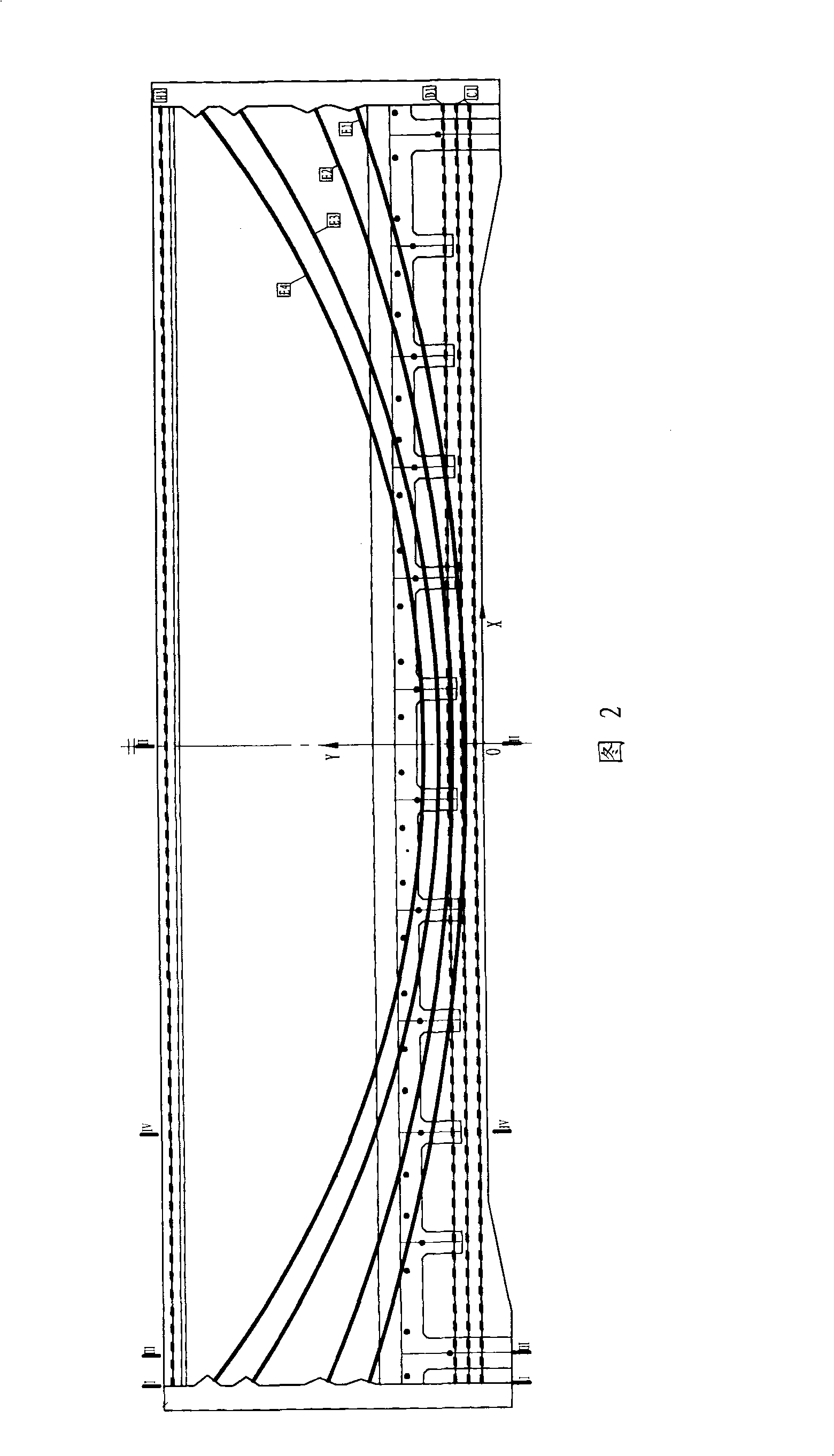

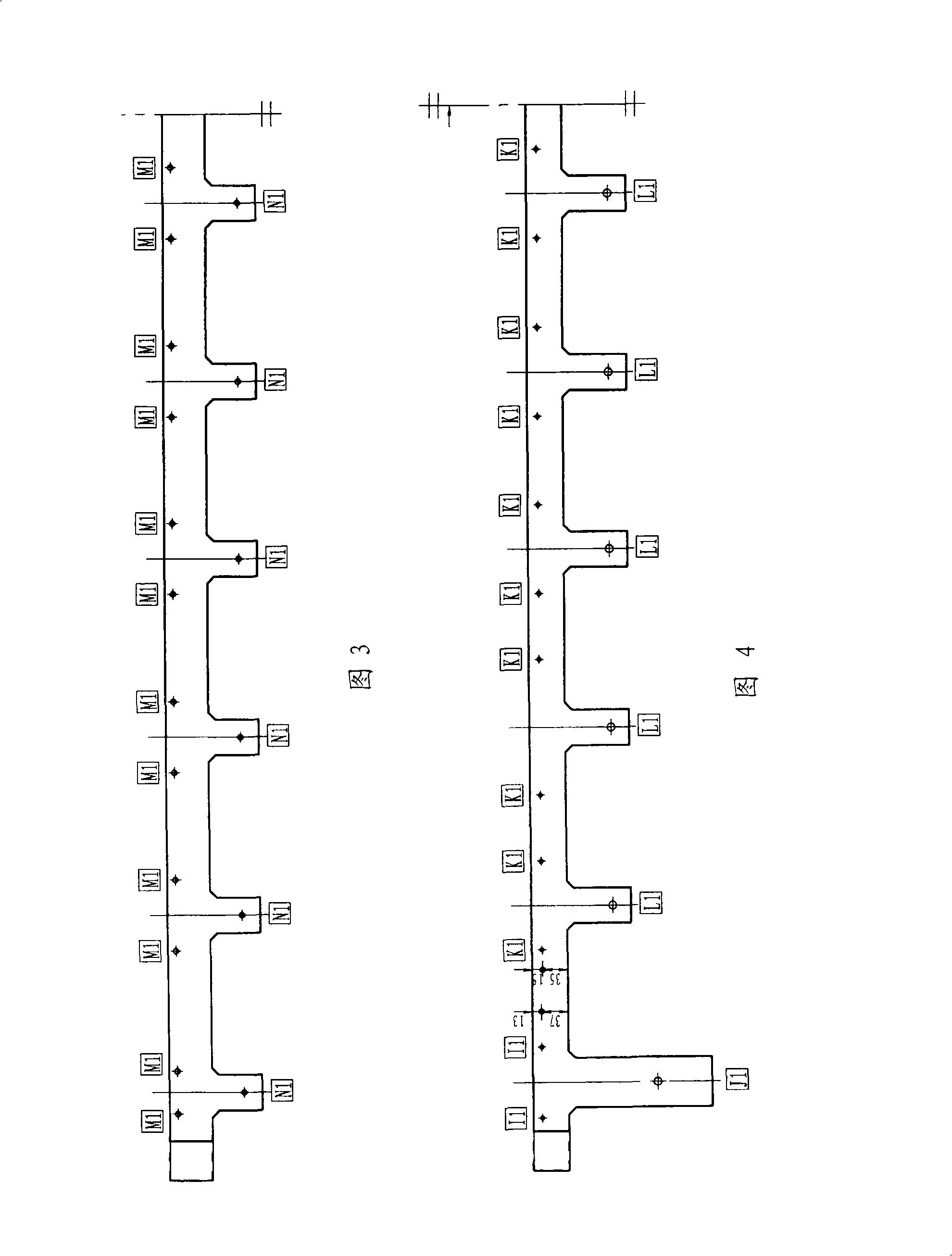

Image

Examples

Embodiment Construction

[0023] The implementation process of the present invention is as follows:

[0024] 1. Material entry: steel hinge line entry inspection, setting out, off-line, numbering; fixed end anchorage production, bundling, classification; anchorage inspection, warehousing, classification placement; bellows inspection, stacking.

[0025] 2. Bellows installation: When the bellows are installed after the bottom net steel bars and lateral steel bars are bound, control the coordinate size of the section and the vector height of each hole marked on the template according to the drawing, and the measurement allowable error is ±5mm , Fix the bellows on the stirrups with the erecting steel bars, and control the left and right positions of the bellows to weld the erecting steel bars and the stirrups to prevent the bellows from shifting or floating. During installation, special bellows joints are used for the extension of the bellows, and the outer edge of the lap joint is tightly wrapped with sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com