Rubber tyre simulated temperature measurement method and apparatus

A technology of rubber tires and temperature measuring devices, which is applied to thermometers, thermometers and measuring devices using electrical/magnetic components directly sensitive to heat, etc. , to achieve the effect of increasing the number of temperature measurements and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

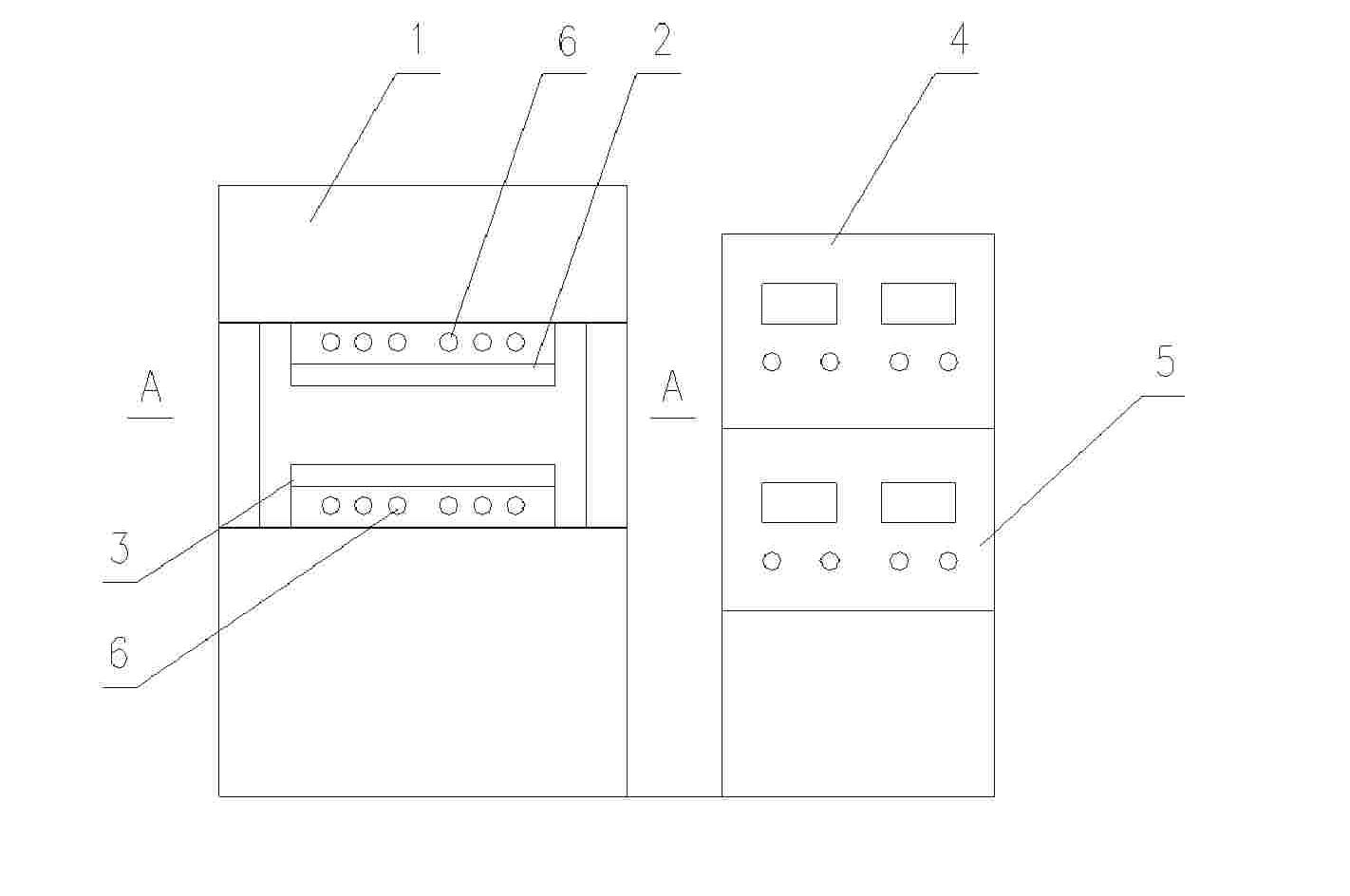

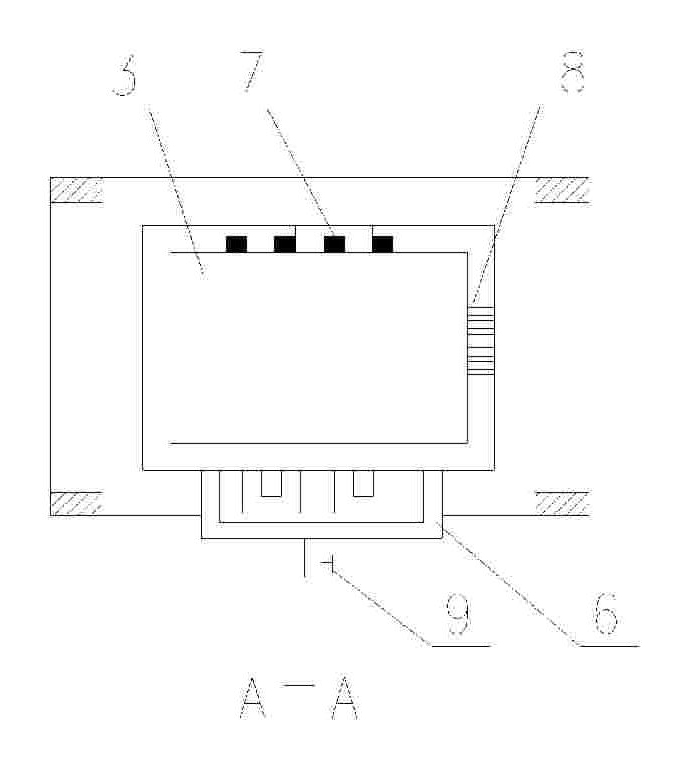

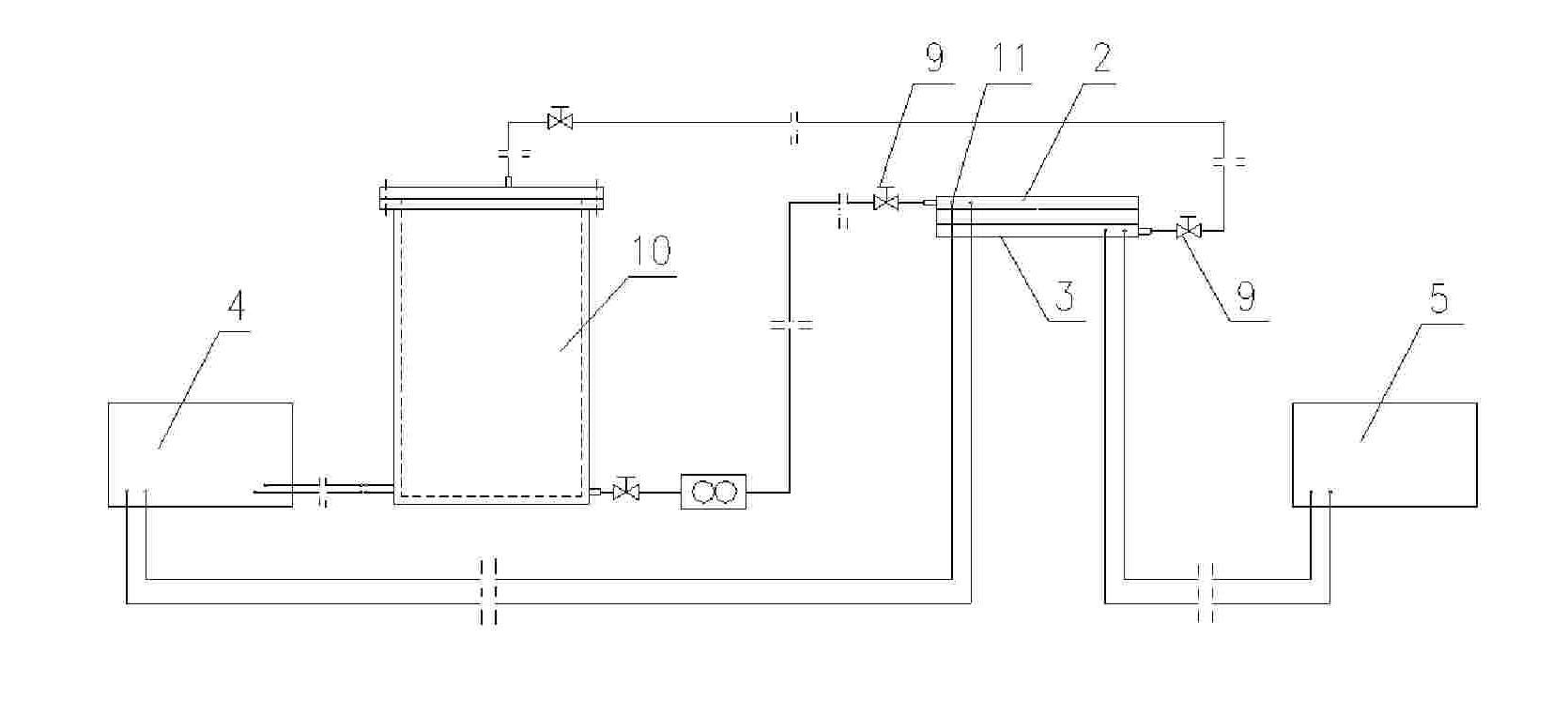

[0017] Embodiments of the present invention: as figure 1 , 2 As shown, the composition of the rubber tire simulation device of the present invention includes a frame 1 and an upper template 2 and a lower template 3 respectively mounted on the upper and lower parts of the frame 1, and electric heating is installed on the upper template 2 and the lower template 3. device 7 and cooling oil pipe 6, and a control valve 9 is also provided on the cooling oil pipe 6, which can heat or force cool the upper template 2 and the lower template 3. Wherein the electric heater 7 adopts a commercially available resistance type heating device, and the cooling oil pipes 6 installed on the upper template 2 and the lower template 3 have independent circuits respectively, and are respectively connected to the oil tank 10 through oil pipelines, thereby the upper template 2, the lower template The template 3 is cooled and lowered in temperature respectively. Thermal sensors 11 are pre-embedded insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com