Double-circulation heat exchange device of oven of high-speed vertical enameling machine

A technology of heat exchange device and enamelling machine, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc. It can solve the problems of low mixed air temperature, high inlet temperature, toxic and harmful gases, etc., to improve the temperature after catalysis, The effect of reducing power consumption and increasing production temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

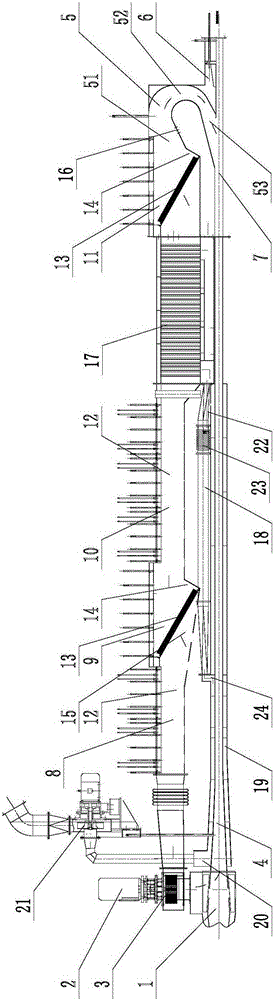

[0017] Such as figure 1 As shown, the high-speed vertical wire drawing enamelling machine oven double-cycle heat exchange device of this embodiment includes an oven hearth 1 and a heating and catalytic zone. The heating and catalytic zone is connected to the furnace evaporation zone 4 through a circulating fan 3 driven by a motor 2. The catalytic zone leads to the hot-blast distribution pipe 5, the end of the hot-blast distribution pipe 5 is equipped with an outlet regulating damper 6, and the outlet of the hot-blast distribution pipe 5 moves towards the channel 7 towards the enameled wire, and the heating catalytic zone includes a catalysis front electric heating zone 8, which is connected successively. The primary catalytic chamber 9, the supplementary heating zone 10 and the secondary catalytic chamber 11 after the primary catalysis, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com